Ultrafiltration/microfiltration membrane and preparation method and use thereof

A microfiltration membrane and filter membrane technology, applied in chemical instruments and methods, other chemical processes, chemical/physical processes, etc., can solve the problems of industrial application difficulties, separation difficulties, adsorbent residues, etc., to solve the problems of adsorbent residues, The effect of high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

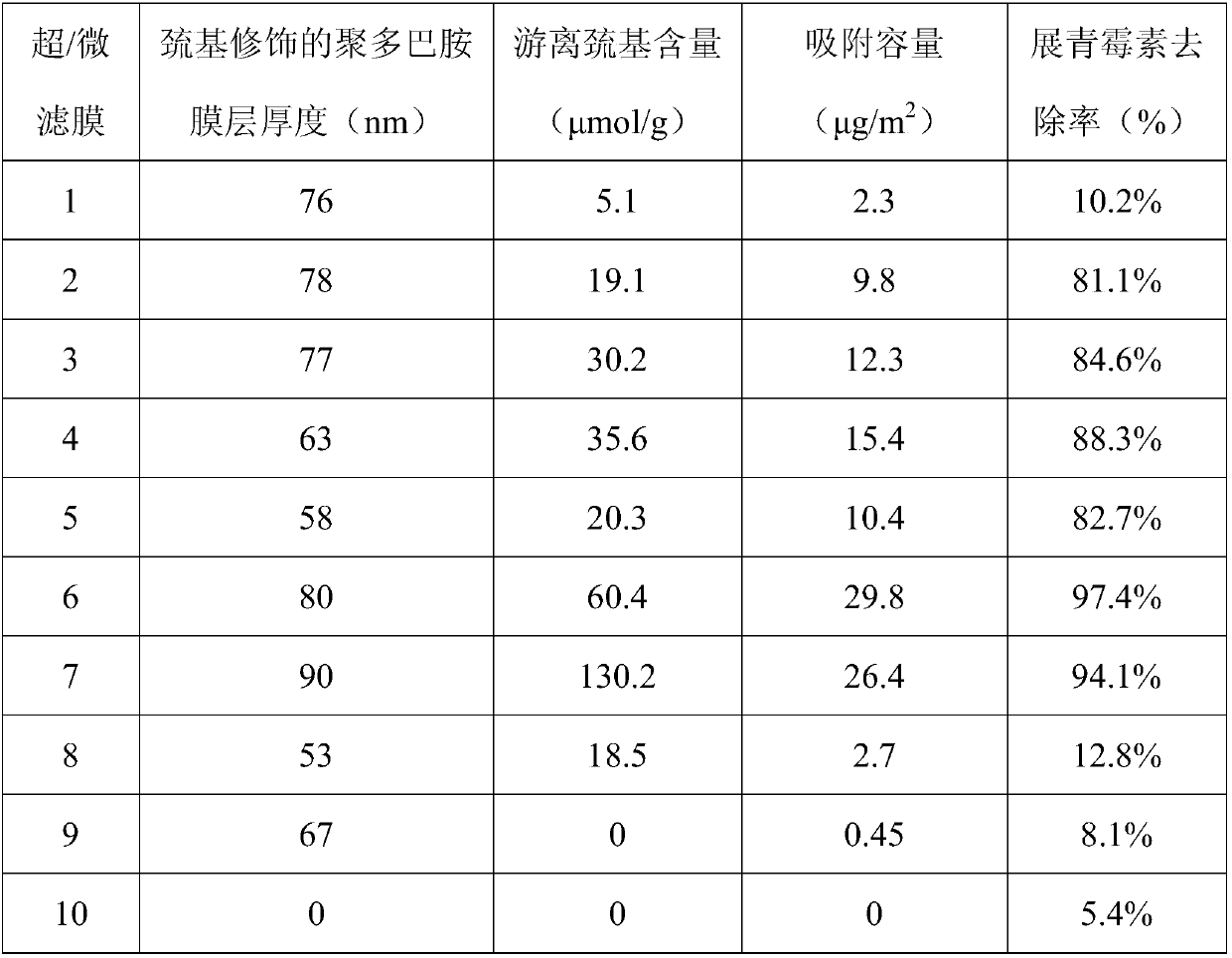

Examples

Embodiment 1

[0050] Prepare the ultra / microfiltration membrane 1 through the following steps:

[0051] In step (1), dopamine is dissolved in tris buffered solution to form a dopamine solution with a concentration of 5 mg / mL and a pH of 8.2, and a polyethersulfone hollow fiber ultrafiltration membrane with a molecular weight cut-off of 12 kDa as a substrate The filter membrane is soaked in the dopamine solution, and the temperature of the dopamine solution is maintained at 25°C, so that the dopamine self-polymerizes in the solution. After 12 hours of self-polymerization, the dopamine self-polymer is deposited on the surface of the matrix filter membrane to obtain polydopamine. film layer;

[0052] In step (2), soak the polydopamine film layer obtained in step (1) in an aqueous solution of chitosan with a concentration of 10 mg / mL, and perform a Michael addition reaction at 60° C. for 1 h to obtain a polydopamine film modified with amino groups layer;

[0053] In step (3), the polydopamine...

Embodiment 2

[0055] Prepare the ultra / microfiltration membrane 2 through the following steps:

[0056] The difference with Example 1 is only that the aqueous solution of mercaptopropionic acid described in step (3) also needs to be activated before carrying out the amidation reaction, and the activation treatment is to combine mercaptopropionic acid, 1-ethyl-(3 -Dimethylaminopropyl) carbodiimide hydrochloride and N-hydroxysuccinimide are mixed in a molar ratio of 1:1:1, and the mixture is dissolved in 2-(N-morpholine at pH 4.6 ) in ethanesulfonic acid monohydrate buffer solution, and perform activation treatment at room temperature for 24 h.

Embodiment 3

[0058] Prepare the ultra / microfiltration membrane 3 through the following steps:

[0059] The only difference from Example 2 is that the molar ratio of mercaptopropionic acid, 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and N-hydroxysuccinimide is 1:10 :10, the time of activation treatment is 0.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com