Hydrogel adhesive as well as preparation method and application thereof

A hydrogel adhesive and reaction technology, applied in the direction of adhesives, adhesive types, polyether adhesives, etc., can solve insufficient adhesion ability, poor mechanical strength of hydrogel adhesives, easy swelling, etc. problems, to achieve excellent mechanical strength, good biocompatibility, fast bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

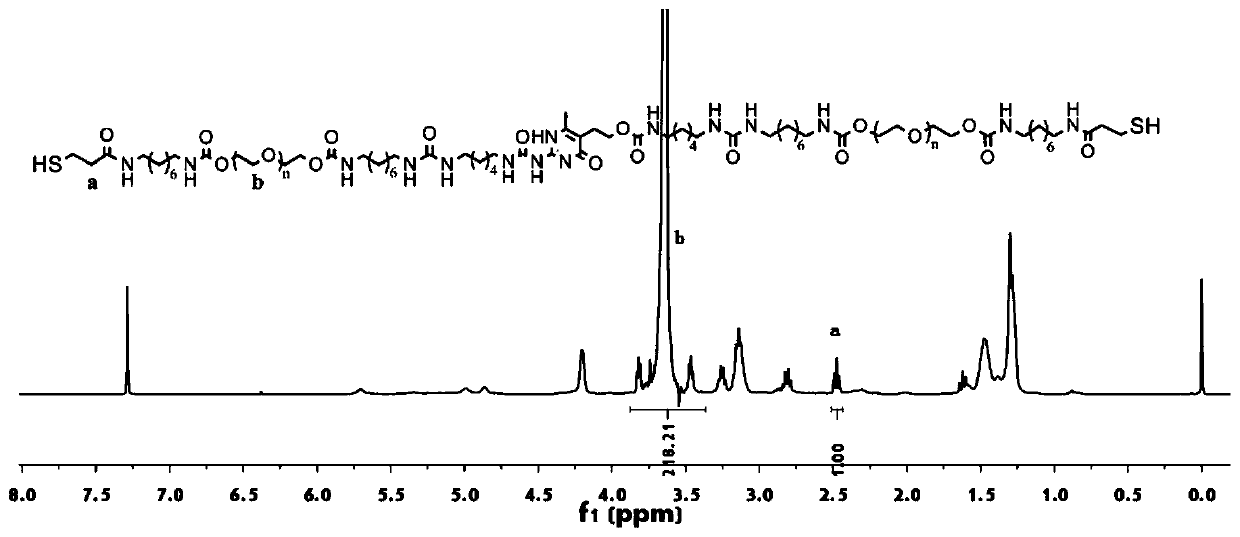

[0056] In the above technical scheme, the mercapto-terminated polyethylene glycol block polymer is a newly prepared polymer of the present invention, but those skilled in the art, based on the structural formula of the mercapto-terminated polyethylene glycol block polymer given in the present invention The preparation method of the polymer can be obtained in combination with the prior art, the present invention provides a preparation method of the polymer, but not limited thereto, the process is:

[0057] Step 1, adding guanidinium carbonate, α-acetyl-γ-butyrolactone and triethylamine into the reaction vessel for reaction to obtain the first intermediate;

[0058] Step 2, adding 1,6-hexamethylene diisocyanate and the first intermediate to the reaction vessel to react to obtain the second intermediate;

[0059] Step 3, adding polyethylene glycol and N,N'-carbonyldiimidazole into the reaction vessel to react to obtain the third intermediate;

[0060] Step 4, add the 3rd interme...

Embodiment 1

[0073] Preparation of Mercapto-terminated Polyethylene Glycol Block Polymer

[0074] Step 1. Add 1.5g of guanidine carbonate, 20ml of absolute ethanol, 2.2ml of α-acetyl-γ-butyrolactone and 5.5ml of triethylamine into the flask, stir and reflux at 90°C for 2h, then cool down to room temperature and keep for 4h Above, the white precipitate was collected, washed with ice ethanol (4° C.) for 2-3 times, and dried to obtain the first intermediate.

[0075] Step 2. Add 1g of the first intermediate, 20ml of 1,6-hexamethylene diisocyanate and 1ml of pyridine into the flask, and raise the temperature to 90°C for 3 hours under the protection of nitrogen until the solution becomes completely transparent. Then, the reaction solution is directly precipitated in a 400ml normal In pentane, the second intermediate was collected.

[0076] Step 3: Add 0.81g of N,N'-carbonyldiimidazole and 15ml of dichloromethane into the flask, dissolve 2g of polyethylene glycol (4000Da in molecular weight) in...

Embodiment 2

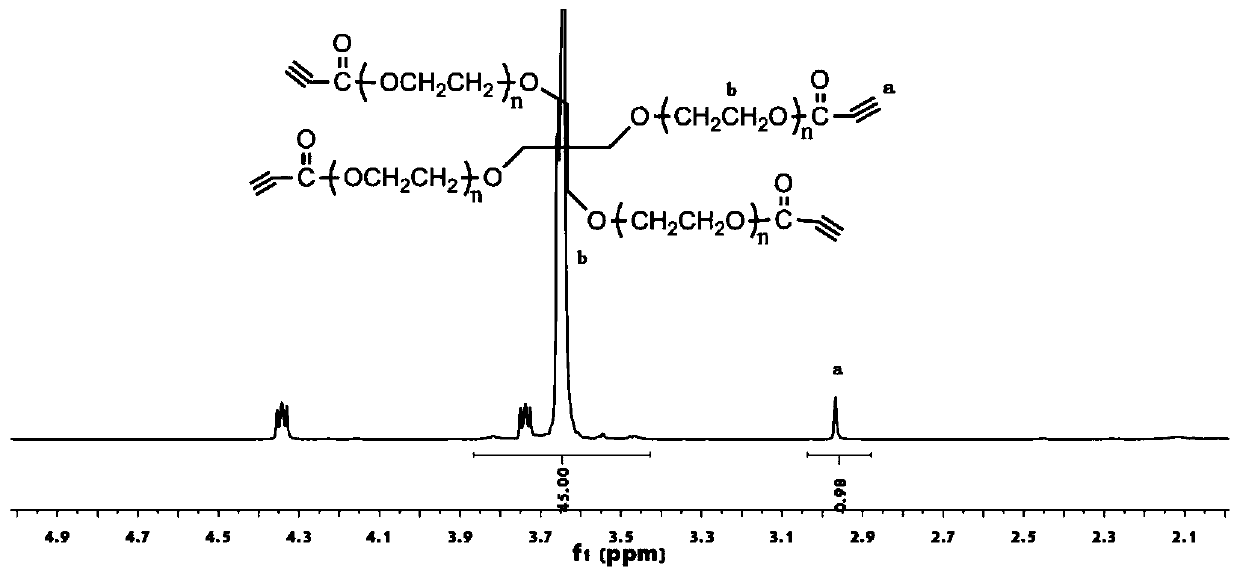

[0081] Preparation of Alkyne-terminated Four-Armed Polyethylene Glycol

[0082] Add 0.5g polyethylene glycol (molecular weight: 2000Da), 0.2g p-toluenesulfonic acid and 50ml cyclohexane into the flask, after heating to 110°C, add 0.22g propiolic acid; connect the Dean-Stark oil-water separator to collect the generated Water, reflux reaction 36h, after the reaction finishes, concentrate the reaction solution, dissolve in 50ml dichloromethane again, extract with saturated sodium bicarbonate solution (twice) and saturated saline (once) respectively afterwards, dry, spin dry solvent, Alkynyl-terminated four-armed polyethylene glycols are obtained.

[0083] Utilize nuclear magnetic resonance to analyze the four-armed polyethylene glycol that the alkynyl end-blocking that embodiment 2 obtains, obtain the nuclear magnetic resonance spectrum, as figure 2 shown. Depend on figure 2 According to the peak integral area ratio of a and b, the alkynyl end-capping degree of the obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com