a fire retardant coating

A technology of fire-retardant coatings and coating additives, which is applied in fire-resistant coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of high product density, the fireproof effect of modified expanded vermiculite is not as good as that of using expanded vermiculite, and the lack of fire-resistant modification of expanded vermiculite. Research and other issues to achieve the effect of avoiding excessive expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

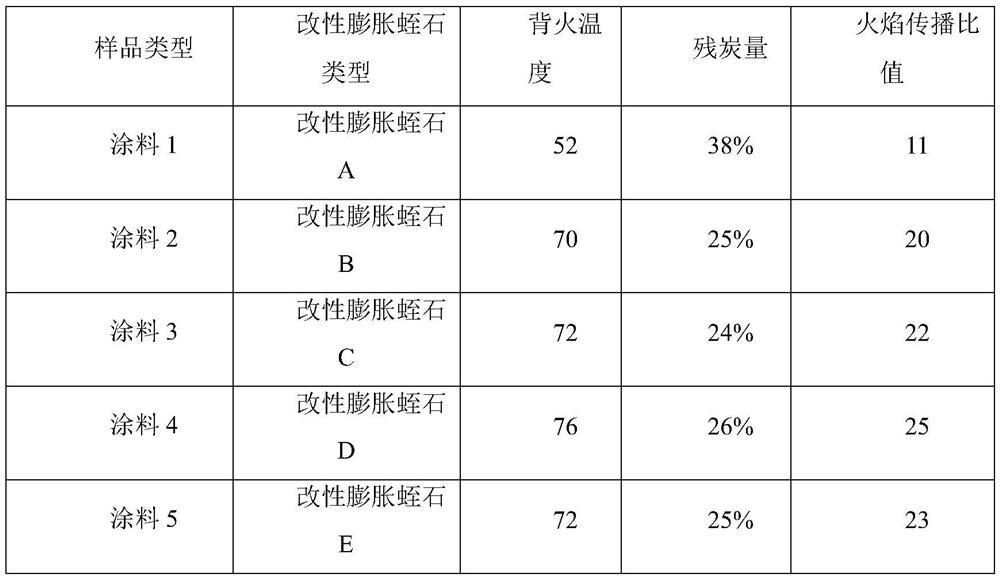

Examples

Embodiment 1

[0034] The preparation method of fire-protected expansion vermiculite a includes the following steps: (1) incomplete expandable calcination of vermiculite: to extract the vermiculite raw material, and in turn into a rotary furnace of 850 ° C, heat expansion for 13 seconds, After the material is not completely expanded, the density is 1050kg / m. 3 ;

[0035] (2) Adding incomplete expansion vermiculum is added to the solvent, stirred and ultrasonically dispersed for 30 minutes to obtain a vermiculite suspension, but the solvent is butanol, and the suspension is added to the cycpoic catalyst to the closed reaction vessel. The temperature is heated to 150 ° C, stirring at high speed and incubated for 3 hours to obtain suspension;

[0036] (3) Add fire modifier to the vermiculite suspension, and perform ultrasonic dispersion 50 minutes; where the fire modifier is composed of a low molecular carbon source and a blowing agent in which the carbon source is pentaerythritol and the foaming...

Embodiment 2

[0039] On the basis of Example 1, the vermiculite heating expansion time and temperature were changed, so that the expansion vermiculum accumulation of the step (1) was 850 kg / m. 3 Other preparation steps, resulting in modified expansion vermiculite B

Embodiment 3

[0041] On the basis of Example 1, the vermiculite expansion time and temperature were changed, so that the expansion vermiculum accumulation density obtained by step (1) was 2000kg / m. 3 The other preparation steps are the same, resulting in modified expansion vermiculite C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com