Ultrathin folded carbon layer coated ZnS composite sandwich material and preparation method and application of ultrathin folded carbon layer coated ZnS composite sandwich material

A technology of interlayer material and carbon layer, which is applied in the field of ultra-thin wrinkled carbon film-coated zinc sulfide composite interlayer material and its preparation, can solve the problems of low conductivity of sulfur and lithium sulfide, complicated preparation process, capacity attenuation, etc., and achieve discharge Excellent capacity, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

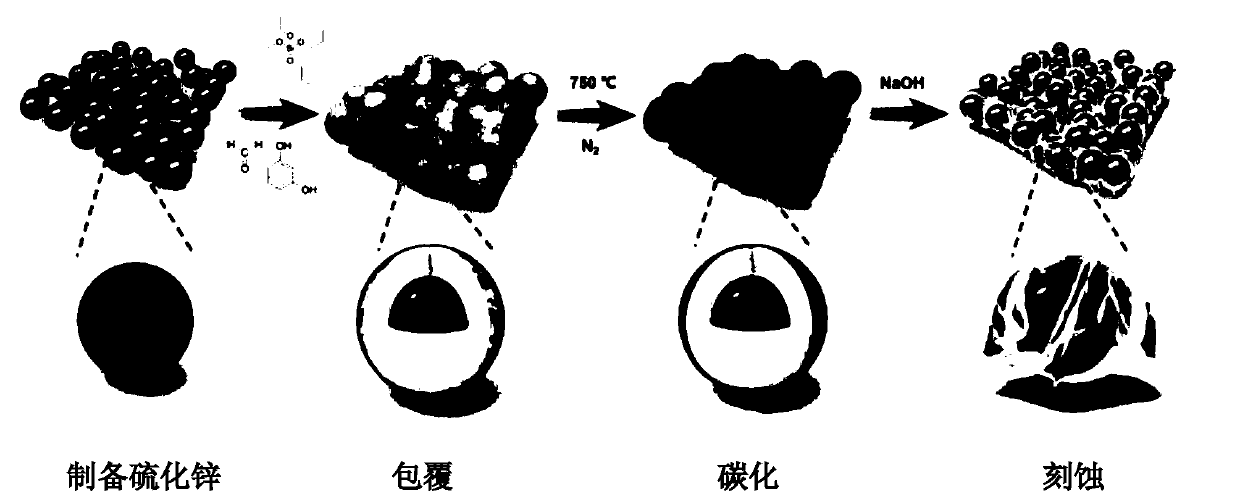

[0034] like figure 1 As shown, the present invention proposes a kind of preparation method of ultra-thin wrinkled carbon layer coating zinc sulfide composite interlayer material, comprises the steps:

[0035] S1: First, disperse zinc acetate and thiourea in water evenly, then add gum arabic and stir evenly to obtain a mixed solution, heat the mixed solution in a hydrothermal reaction kettle, and obtain zinc sulfide nano-microsphere filter cake after suction filtration and washing;

[0036] S2: Disperse the zinc sulfide nanospheres prepared in S1 in a mixed solution of water, absolute ethanol, and ammonia water, add a certain amount of silicon source and stir for a certain period of time, then add a certain amount of resorcinol and formaldehyde solution, The entire mixed solution was stirred at a certain temperature for a certain period of time to obtain an orange precipitate, which was collected by centrifugation and dried to obtain the first intermediate product;

[0037] S3...

Embodiment 1

[0051] S1: Under stirring, add 0.015mol zinc acetate and 0.03mol thiourea to 100ml aqueous solution in turn, and then add 2g gum arabic to obtain a mixed solution; pour the mixed solution into a tetrafluoroethylene tank and place it in a hydrothermal reaction In the still, at 200°C, react for 30h. After the reaction, let the hydrothermal reaction kettle cool down to room temperature naturally to obtain the reaction product zinc sulfide nanospheres;

[0052] S2: Disperse 0.2g of zinc sulfide nanospheres prepared above in a mixed solution of 10ml of water, 100ml of alcohol, and 5ml of ammonia water, add 5ml of methyl orthosilicate and stir at room temperature for 50min; add 100mg of resorcinol to the above solution and 100 μL formaldehyde solution, and the whole mixed solution was stirred at room temperature for 24 hours to obtain an orange precipitate, which was collected by centrifugation and dried at 80° C. to obtain the first intermediate product;

[0053] S3: carbonizing th...

Embodiment 2

[0056] S1: Under stirring, add 0.015mol zinc acetate and 0.028mol thiourea to 100ml aqueous solution in sequence, then add 1.8g gum arabic to obtain a mixed solution; pour the mixed solution into a tetrafluoroethylene tank and place it in a hydrothermal In the reaction kettle, react at 180°C for 24 hours. After the reaction, let the hydrothermal reaction kettle cool down to room temperature naturally to obtain the reaction product zinc sulfide nanospheres;

[0057] S2: Disperse 0.18g of zinc sulfide nanospheres prepared above in a mixed solution of 10ml of water, 90ml of alcohol, and 4ml of ammonia water, add 4ml of methyl orthosilicate and stir at room temperature for 30min; add 80mg of resorcinol to the above solution and 80 μL formaldehyde solution, and the whole mixed solution was stirred at room temperature for 20 hours to obtain an orange precipitate, which was collected by centrifugation and dried at 80° C. to obtain the first intermediate product;

[0058] S3: carboniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com