Gold magnetic composite microspheres with monodispersity and superparamagnetism and preparation method thereof

A composite microsphere and superparamagnetic technology, applied in the direction of diamagnetic/paramagnetic materials, magnetic materials, magnetic objects, etc., can solve the problems of poor dispersion, complex process and weakening of composite materials, achieve good stability and avoid agglomeration , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

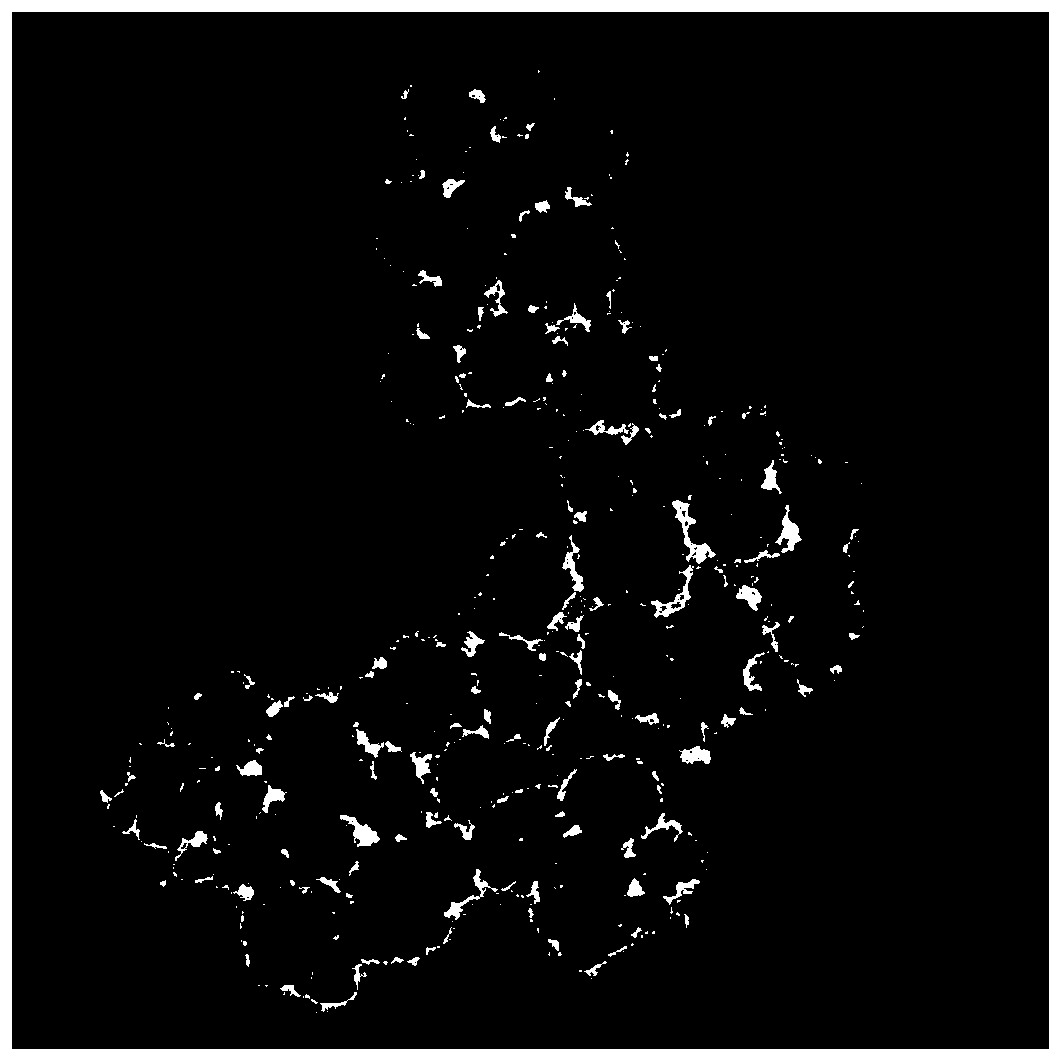

[0036] The preparation method of the gold magnetic composite microsphere with monodisperse and superparamagnetic of the present invention comprises the steps:

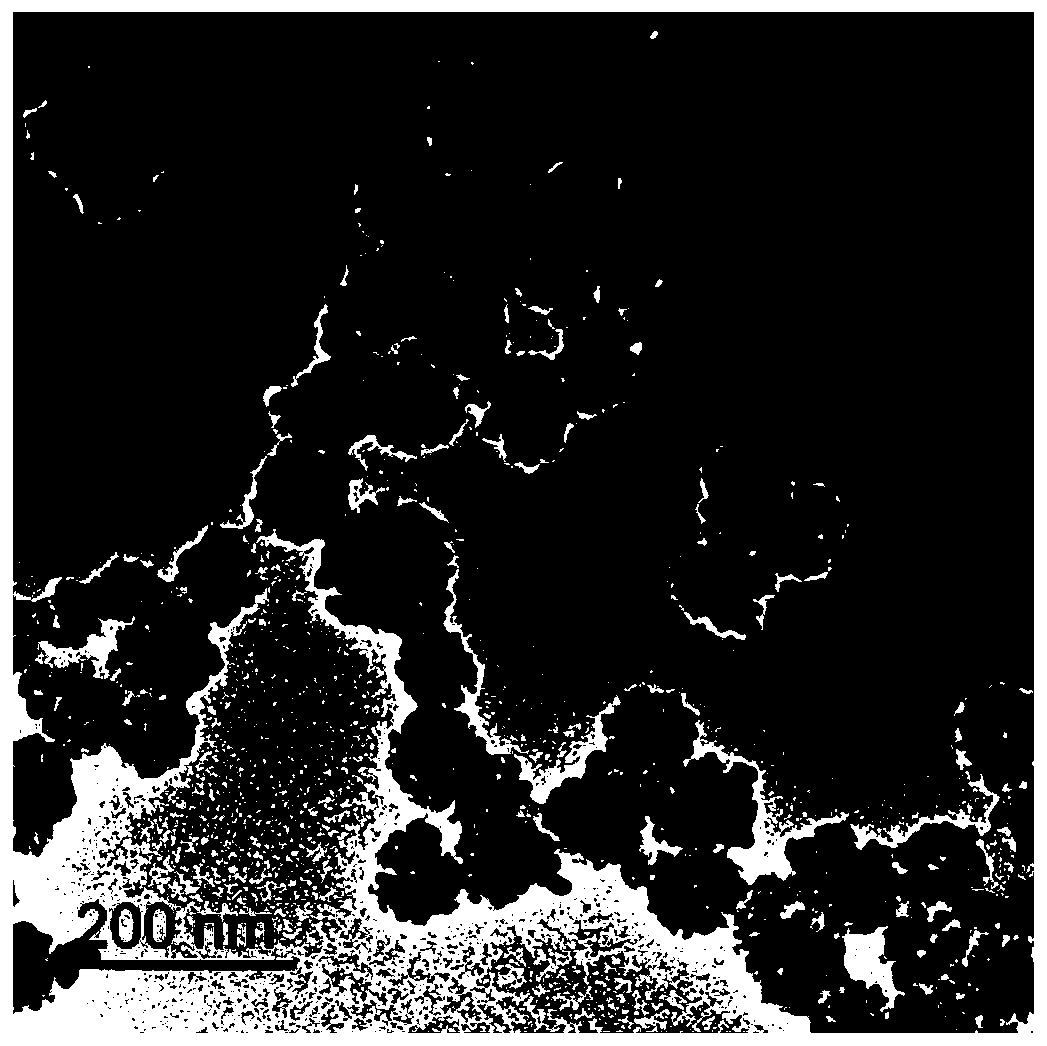

[0037] (1) Preparation of mesoporous Fe by solvothermal method 3 o 4

[0038] FeCl 3 ·6H 2 O and sodium acetate are placed in a round-bottomed flask, and 1,2-propylene glycol solution is used as a solvent, stirred and ultrasonically dissolved to make it uniform, and then, the stirred mixture is heated to 90-110°C, and transferred to polytetrafluoroethylene for reaction In the kettle, react at 160-200°C for 8-10 hours. After the reaction, the black precipitate was collected by magnetic separation with a magnet, and washed several times alternately with ultrapure water and absolute ethanol until the cleaned supernatant was clear, and finally freeze-dried, and the obtained powder was mesoporous Fe 3 o 4 . where FeCl 3 ·6H 2 The molar ratio of O to sodium acetate is (0.1-0.15):1.

[0039] (2) Reducing agent on me...

Embodiment 1

[0044] (1) Preparation of mesoporous Fe by hydrothermal method 3 o 4

[0045] 5mmolFeCl 3 ·6H 2 O and 50mmol sodium acetate were placed in a round-bottomed flask, and 40ml of 1,2-propanediol solution was taken as a solvent, stirred and ultrasonically dissolved to make it uniform, and then, the stirred mixture was heated to 90°C, and transferred to polytetrafluoroethylene In the reaction kettle, react at 160°C for 8h. After the reaction, the black precipitate was collected by magnetic separation with a magnet, and washed several times alternately with ultrapure water and absolute ethanol until the cleaned supernatant was clear, and finally freeze-dried, and the obtained powder was mesoporous Fe 3 o 4 .

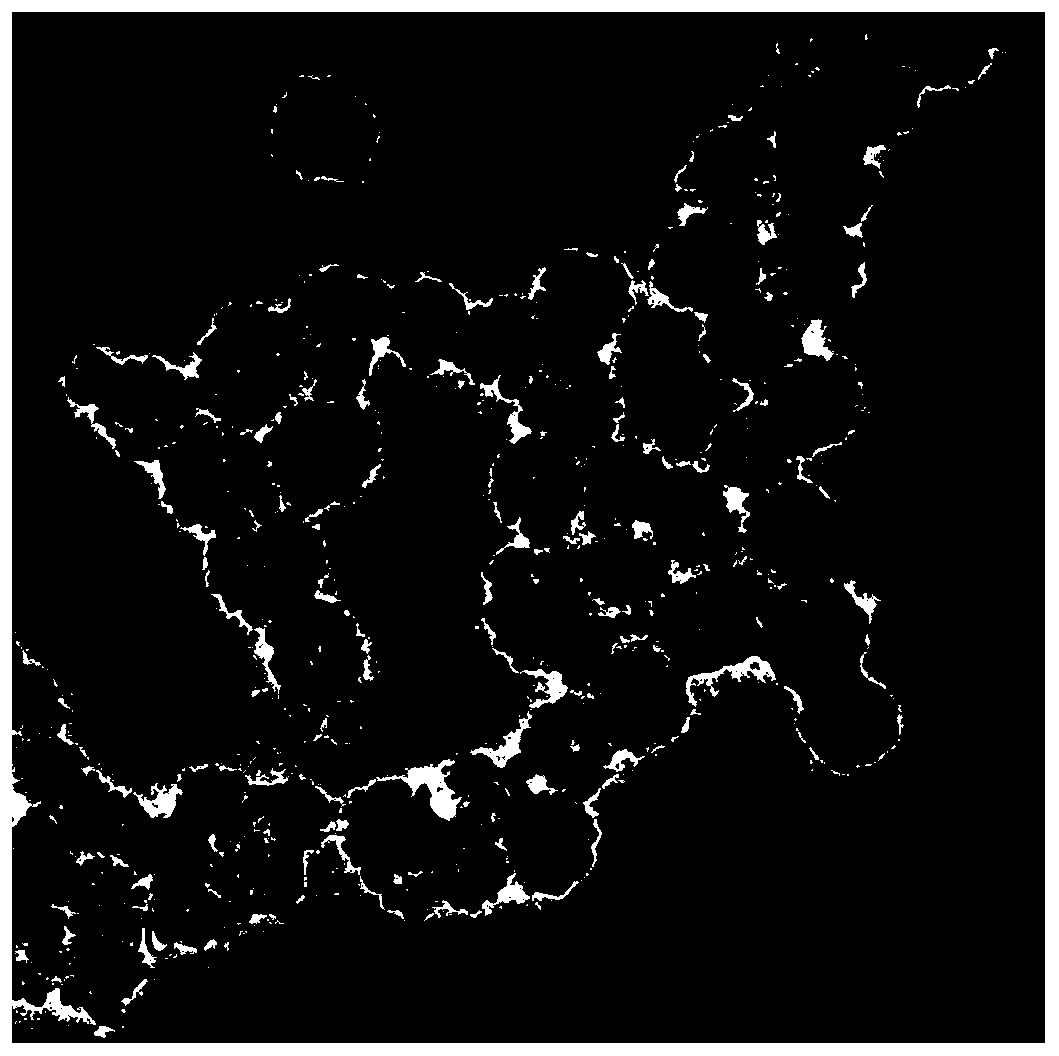

[0046] (2) Reducing agent on mesoporous Fe 3 o 4 surface modification

[0047] Take 0.05g of anhydrous sodium citrate and dissolve it in 100ml of ultrapure water. After the dissolution is complete, add 100mg of mesoporous Fe prepared in (1). 3 o 4 , the mixture was m...

Embodiment 2

[0051] (1) Preparation of mesoporous Fe by hydrothermal method 3 o 4

[0052] 5mmolFeCl 3 ·6H 2 O and 50mmol sodium acetate were placed in a round-bottomed flask, and 40ml of 1,2-propanediol solution was taken as a solvent, stirred and ultrasonically dissolved to make it uniform, and then, the stirred mixture was heated to 95°C, and transferred to polytetrafluoroethylene React for 10 hours at 180°C in the reactor. After the reaction, the black precipitate was collected by magnetic separation with a magnet, and washed several times alternately with ultrapure water and absolute ethanol until the cleaned supernatant was clear, and finally freeze-dried, and the obtained powder was mesoporous Fe 3 o 4 .

[0053] (2) Reducing agent on mesoporous Fe 3 o 4 surface modification

[0054] Take 0.10g of anhydrous sodium citrate and dissolve it in 100ml of ultrapure water. After the dissolution is complete, add 100mg of mesoporous Fe prepared in (1). 3 o 4 , the mixture was mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com