Preparation of metal-loaded catalyst with bean dreg-derived nitrogen-doped carbon base as carrier and method for catalyzing hydrodeoxygenation of p-nitrophenol

A technology of p-nitrophenol and supported catalysts, which is applied in the preparation of organic compounds, preparation of amino hydroxyl compounds, chemical instruments and methods, etc., to achieve the effects of simple preparation process, resource saving, and low toxicity of reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a metal-supported catalyst based on a nitrogen-doped carbon base derived from okara and catalyzing the hydrodeoxygenation of p-nitrophenol, comprising the following steps:

[0027] S1. Wash, dry and grind the bean dregs and pass through a 40-mesh sieve. Under the condition of nitrogen protection, roast the treated bean dregs in a tube furnace at 300°C for 2 hours, collect the roasted bean dregs and add potassium hydroxide solution , stirred at room temperature for 30 minutes and then filtered. The filtered bean dregs were washed with water, and the pH was adjusted to neutral to obtain a crude product. The crude product was dried naturally and ground to obtain a crude product. After weighing, it was placed in a tube under nitrogen protection. Roasting in a furnace at 800°C for 2 hours, grinding the product after the roasting treatment to obtain a nitrogen-carbon carrier;

[0028] S2. Disperse the nitrogen-carbon carrier in methanol at room temperat...

Embodiment 2

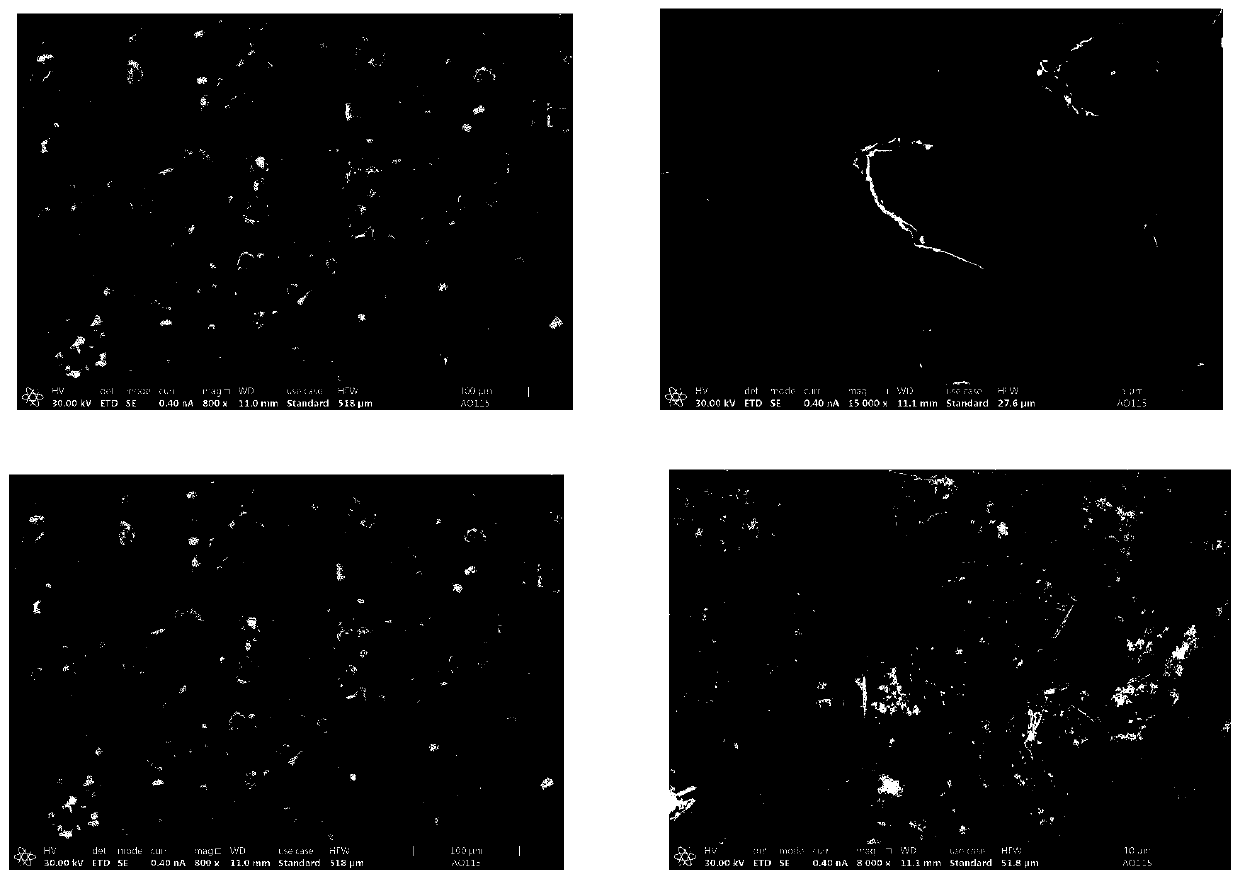

[0032] According to embodiment 1, adopt field emission scanning electron microscope (SEM) to characterize the morphology and particle distribution of sample; Adopt elemental analysis (EDS) to determine the kind and content of the element contained in catalyst; Adopt X-ray diffractometer (XRD) to measure sample The structure, composition and crystallinity of the sample were tested and analyzed by X-ray photoelectron spectroscopy (XPS).

[0033] figure 2 It is the SEM topography image of the Pd / NC catalyst, and Table 1 shows the element distribution results of the nitrogen-doped carbon-based support. It can be seen from the table that the heteroatom nitrogen was successfully introduced into the carbon base by the method of okara calcination, and the nitrogen content exceeded 11%. achieved the intended purpose.

[0034] Table 1 Element distribution results on the surface of Pd / NC catalyst

[0035]

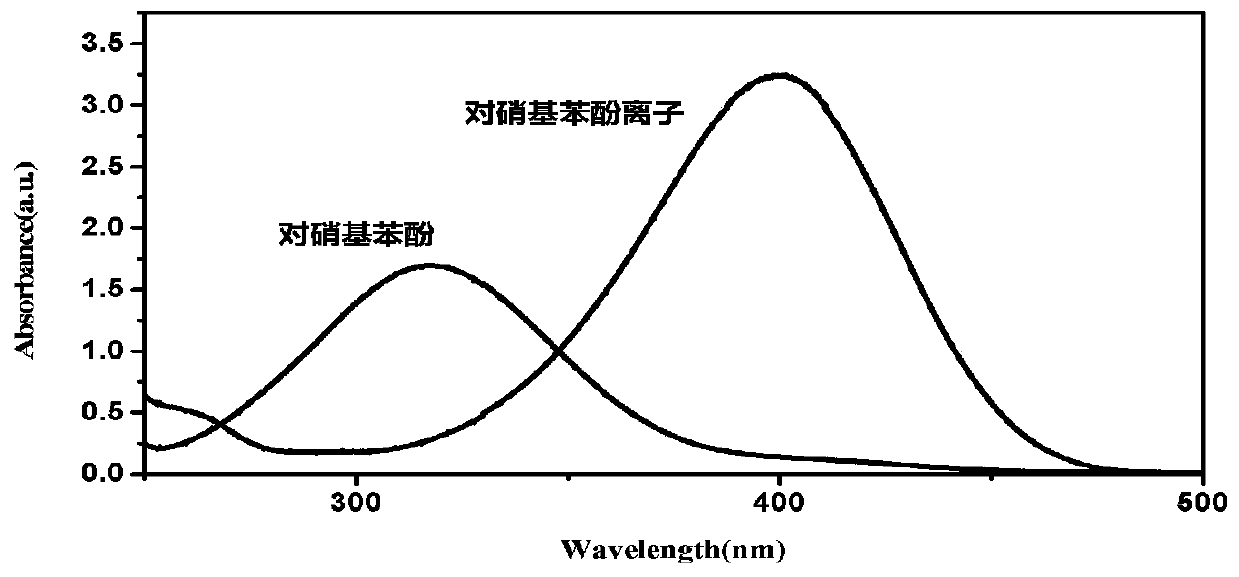

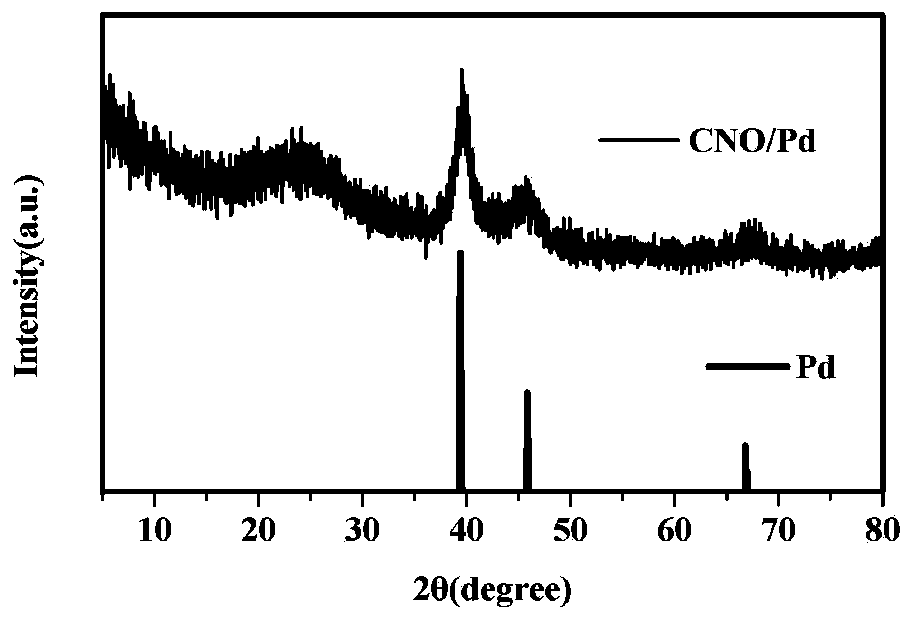

[0036] image 3 It is the XRD characteristic diffraction pattern of metal...

Embodiment 3

[0043] Effect of Metal Content on Reaction

[0044] According to Application Example 1, this experiment used the nitrogen-carbon material prepared from bean dregs as the carrier and metal Pd as the load to investigate the catalytic reaction time required for the metal Pd-supported catalyst with different mass fractions under the same conditions. The results are shown in Figure 7 As shown, it can be seen that with the continuous increase of the mass fraction of Pd contained in the catalyst, the required reaction time is constantly decreasing, indicating that within a certain range (this experiment is a Pd content of 2% to 10%), the same Under the reaction conditions (Pd is the supported metal and the carrier is the carbon-nitrogen material derived from bean dregs), the catalytic effect of 4-NP hydrogenation is the best when the Pd content is 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com