Self-adhesive multilayer composite flexible decoration sheet preparation process

A technology of composite flexibility and preparation process, applied in the direction of adhesive types, polymer adhesive additives, film/sheet adhesives, etc., can solve the problems of reducing acrylic polymers, sheet surface cracks, aging, etc. , to achieve the effect of improving viscosity and hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The specific preparation process of the antioxidant acrylic polymer emulsion is as follows:

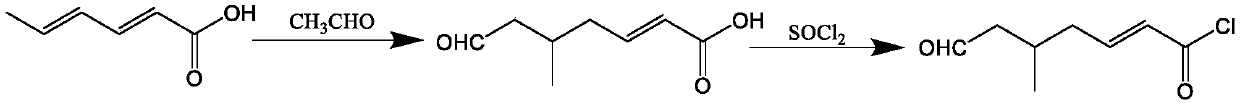

[0026] ① Add 11.2g (0.1mol) of sorbic acid to 60mL of ether solution, stir to dissolve and add 5.3g (0.12mol) of acetaldehyde to it, then increase the temperature to 80-85℃, and then add 6mL dropwise to it. 4% sodium hydroxide solution, control the dropping rate to 4-5mL / min, after the dripping is complete, stir and reflux for 3-4h, and then add dropwise a 2% hydrochloric acid solution with a mass concentration to the solution to pH=1, and then Add 14.3g (1.2mol) of thionyl chloride, keep the temperature constant and reflux for 6-7h, and then perform vacuum distillation to obtain product A, the reaction structure is shown below;

[0027]

[0028] ②Weigh 21.4g of 2,4-dihydroxybenzophenone and 130mL of carbon tetrachloride and add them to the reactor, stir and mix, and raise the temperature to 55-60℃, then add 45.5g of the product A prepared in step ① to it, and heat up Stir the reac...

Embodiment 2

[0032] The specific preparation process of the flexible sheet is as follows:

[0033] Step 1: Put the mineral powder into a muffle furnace at 280-300℃ and roast for 25-26h. After cooling to room temperature, add 1kg of mineral powder into 2L of 8% sodium hydroxide solution, stir and mix for 30-40min, then wash to Dry after neutralization to obtain pre-activated mineral powder (Ac-BZ);

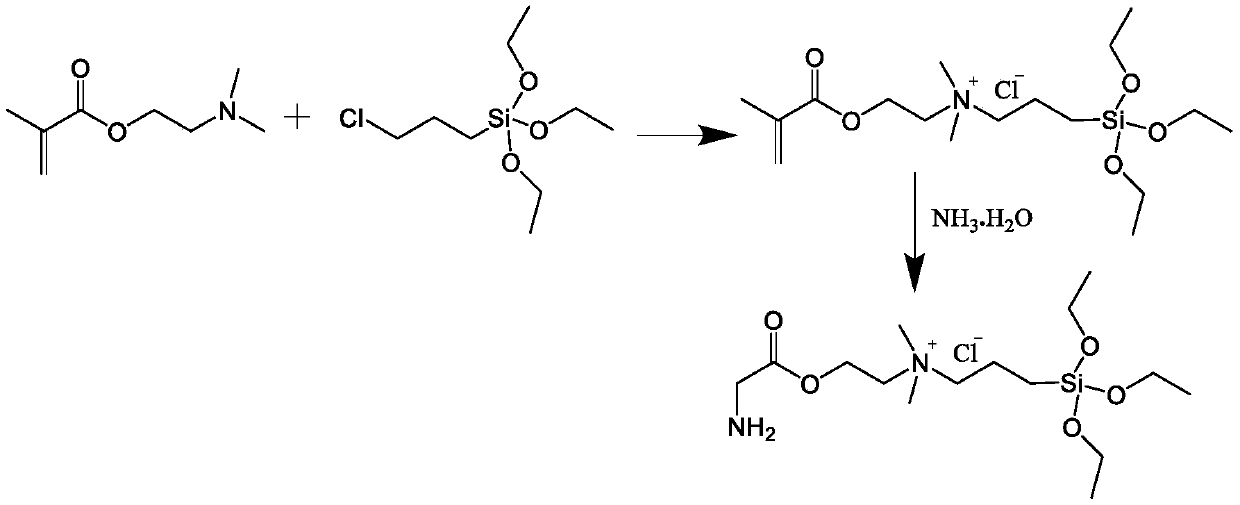

[0034] Step 2: Add 15.7g of dimethylaminoethyl methacrylate, 22.1g of coupling agent KH550 and 200mL of absolute ethanol into the reaction vessel at a certain ratio at the same time, and then heat to 75-80°C and reflux for 4h, then evaporate to remove After the solvent is cooled to 50-60°C, 12.5g of concentrated ammonia is added to the reaction vessel, and the reaction is refluxed for 12-14h, and then vacuum distillation is performed to obtain the modifier. The reaction structure is as follows:

[0035]

[0036] Step 3: Add 16 g of the modifier prepared in step 2 to 800 mL of ethanol solution and sti...

Embodiment 3

[0039] The specific preparation process of the colored flexible sheet is as follows: 100g of the NH prepared in Example 2 2 -BZ, 73g of the antioxidant acrylic polymer emulsion prepared in Example 1, 13g of water and 26g of dyeing slurry, the mass concentration of the direct dye in the dyeing slurry is 75%, and at the same time, add it to the reaction vessel and stir and mix for 1-2min, then add 11g of flexible agent was added and stirred and mixed for 2-3 minutes to obtain a slurry. After the addition of the anti-oxidant acrylic polymer emulsion, the mold was immediately controlled within 2 hours, and then the obtained slurry was poured into the mold for uniform coating and cured at 100°C 3-4h, then demoulding and drying to obtain a colored flexible sheet.

[0040] Comparative example 1:

[0041] The specific preparation process of the colored flexible sheet is as follows: 100g of the NH prepared in Example 2 2 -BZ, 73g (WA-103) water-based acrylic emulsion, 13g water and 26g dyei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com