Method for repairing graphite structure in reduced graphene oxide and application of nitrogen-doped reduced graphene oxide

A technology of graphite structure and graphene, applied in the application of nitrogen-doped reduced graphene oxide, repairing the field of graphite structure in reduced graphene oxide, can solve the problem of affecting the physical and chemical properties of graphene, low specific capacitance, and destroying the integrity of graphite structure In order to achieve the effects of large-scale production, mild conditions and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

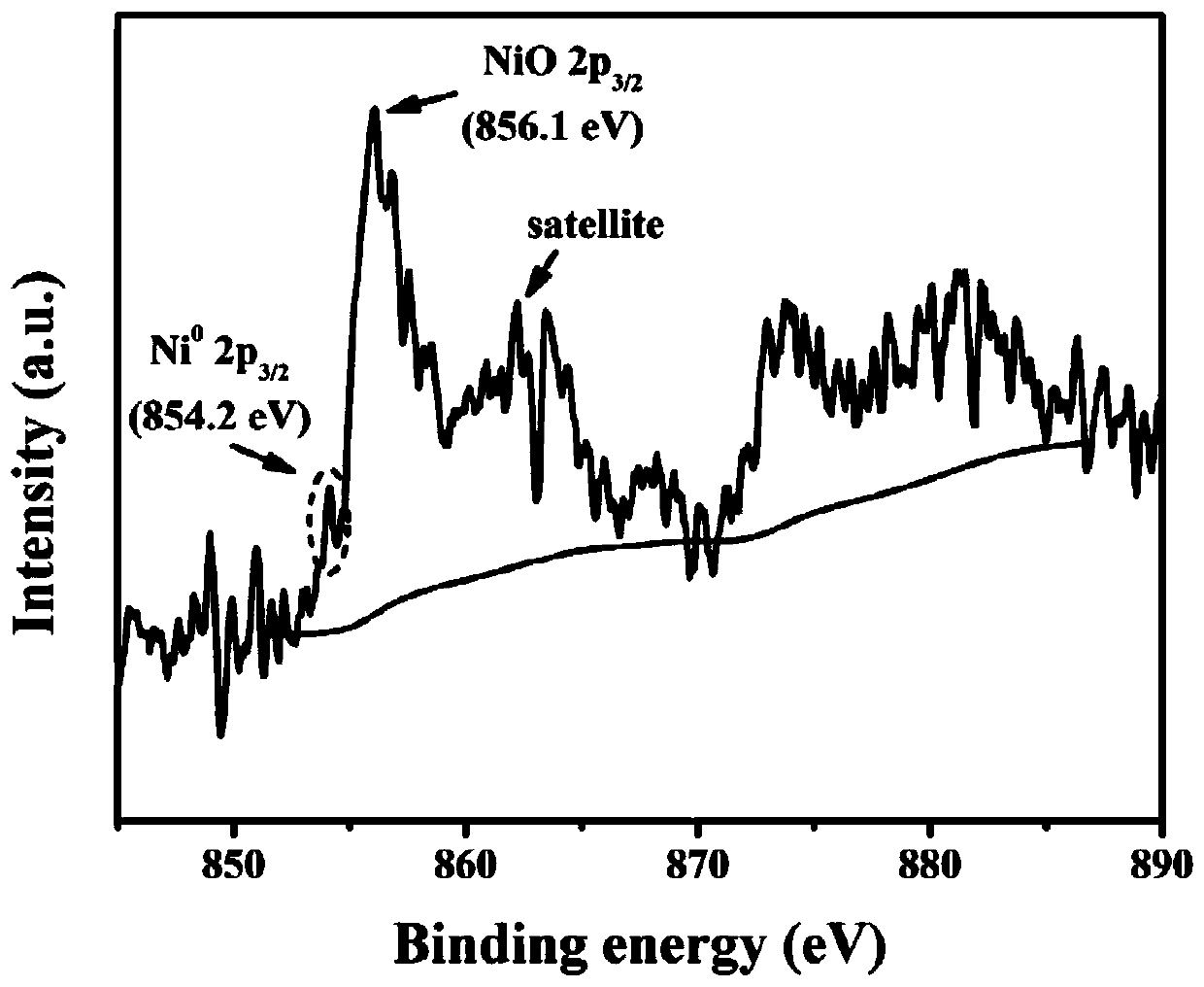

[0030] Under stirring conditions, 6 mL of pyridine was added to the suspension of 3.5 mL of graphene oxide, and then 33.3 mg of nickel sulfate hexahydrate was dissolved in 10.5 mL of deionized water and added to the above solution; the mixed solution was sealed in poly Then the container was kept at 180°C for 6 hours; the polytetrafluoroethylene container was cooled to room temperature and the solution was freeze-dried, and the resulting solid was calcined at 300°C for 1 hour at a heating rate of 5°C / min. Hour. After cooling down to room temperature, wash with 300mL 1M hydrochloric acid and 1000mL deionized water, and dry; carry out XPS spectrogram analysis on the sample that has not been washed with 1M hydrochloric acid after calcination, and the figure 2 As can be seen, it can be seen that it contains a trace amount of nickel elemental substance through its nickel peak, and these trace amounts of nickel elemental substance can catalyze pyridine to form nitrogen-doped graphi...

Embodiment 2

[0032] The application of the nitrogen-doped reduced graphene oxide prepared on supercapacitor electrode materials comprises the following steps under optimal conditions:

[0033] Carbon black, polytetrafluoroethylene suspension and the prepared nitrogen-doped reduced graphene oxide are mixed in a mass ratio of 1:1:8 to form a slurry, and then the coating is coated on a stainless steel current collector (1cm -2 ), and then pressed at a pressure of 20 MPa for 10 minutes to make it closely contact with the current collector, and then vacuum-dried at 80°C for 24 hours. Obtain the electrode material that can be applied on the supercapacitor; In the three-electrode system, the silver / silver chloride electrode is used as the reference electrode, the platinum electrode is used as the counter electrode, and the electrolyte is 6M potassium hydroxide; in the two-electrode system, the The prepared two electrode materials and the cellulose separator were assembled into a "sandwich" type; ...

Embodiment 3

[0041] Embodiments 1 and 2 are the best preferred schemes of the present invention, and the following Table 1 and Table 2 are the single factor optimization experiments carried out in the process of obtaining the best preferred schemes of Example 1 in obtaining Examples 1 and 2. Except that the conditions considered to be investigated are different from those in Example 1, other conditions are the same as in Examples 1 and 2.

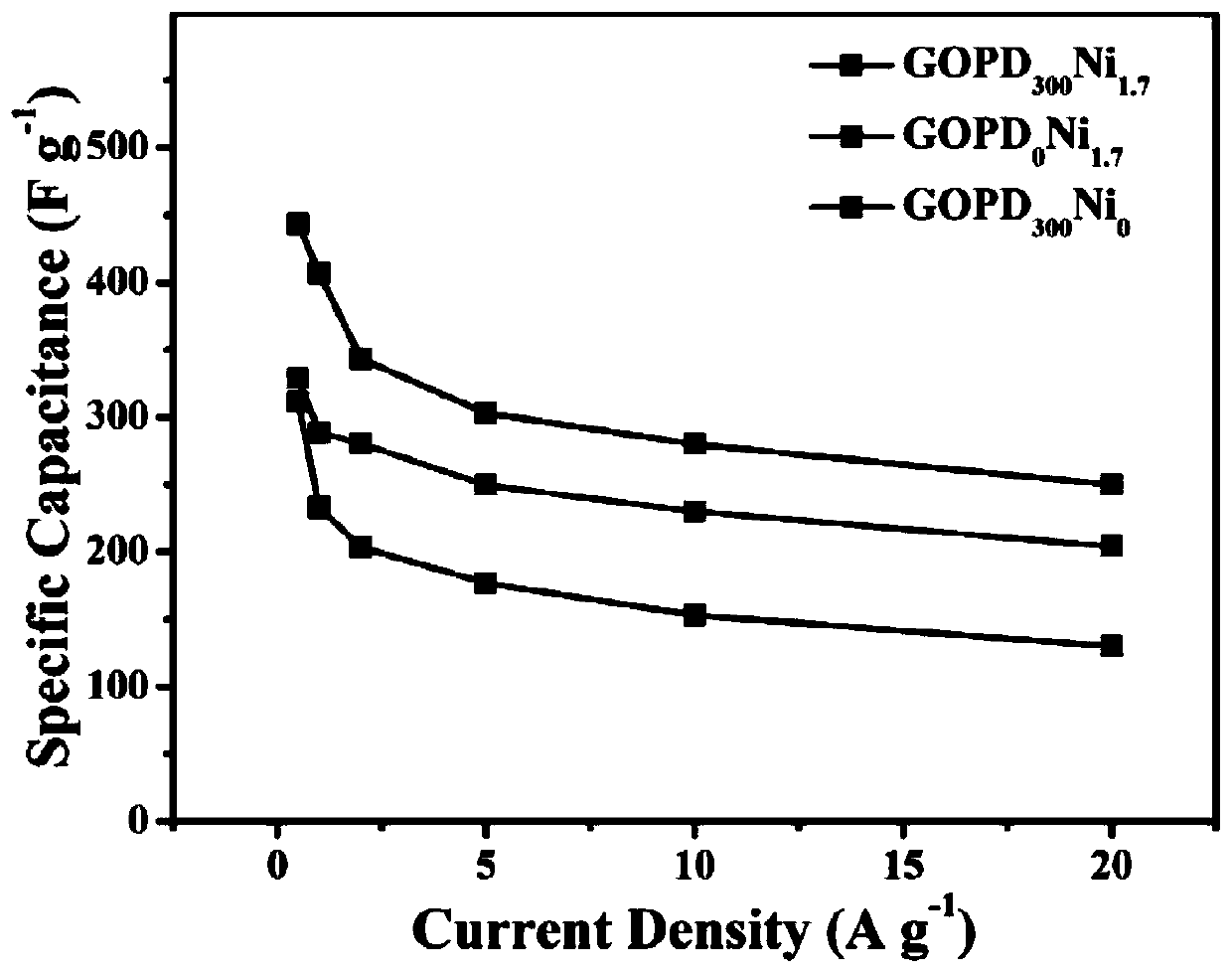

[0042] Capacitance data table under different current densities of materials prepared by the technology of the present invention under different pyridine ratios in table 1

[0043] Current density (A / g) 1 2 5 10 20 GOPD 300 Ni 1.7 (F / g)

416.2 347.6 315.0 293.0 264.0 GOPD 250 Ni 1.7 (F / g)

368.1 308.2 272.5 245.0 224.0 GOPD 350 Ni 1.7 (F / g)

384.6 315.4 286.5 263.0 234.0

[0044] Capacitance data table of the material prepared by the technology described in the present invention under diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com