Iridium complex, preparation method, and application thereof

An iridium complex and coordination technology, applied in indium organic compounds, chemical instruments and methods, platinum group organic compounds, etc., can solve problems such as poor carrier transport ability, and achieve good carrier transport ability and chemical properties. Stable, high synthetic yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Preparation of THF solution of lithium salt of thioamide substituted with auxiliary ligand isopropyl diphenylamino group

[0073] Diphenylamine and n-butyl lithium are reacted to extract hydrogen in THF solution at low temperature, and then reacted with isopropyl isothiocyanate to obtain the lithium salt THF solution of isopropyl diphenylamino thioamide Directly used in the next step of the synthesis of complex reaction.

[0074] The above method can be used to prepare other thioamide lithium salt THF solutions:

[0075]

Embodiment 2

[0076] Example 2 Preparation of the iridium complex of the present invention

[0077] Combine the main ligand 1-(4-(trifluoromethyl)phenyl)isoquinoline and IrCl 3 Reflux in the ethoxyethanol solution at a ratio of 2:1 for 10 hours, cool and filter to obtain the chlorine bridge complex of iridium; then 10mmol (15.43g) of the chlorine bridge complex and 20mmol of isopropyl diphenylamino thioamide The THF solution of the lithium salt was stirred in the ethylene glycol dimethyl ether solution at room temperature for one hour to obtain the crude product of the iridium complex. The column chromatography obtained 16.11 g of pure Samc 8 (yield: 80%). And further put 5gSamc 8 in the quartz tube, at 10 -5 Under Pa vacuum conditions, it was purified by heating and sublimation to obtain 3.5 g of luminescent material (sublimation rate 70%) meeting the requirements of the preparation device. The response is as follows:

[0078]

[0079] The obtained iridium complex Samc 8 was analyzed by hydrog...

Embodiment 3

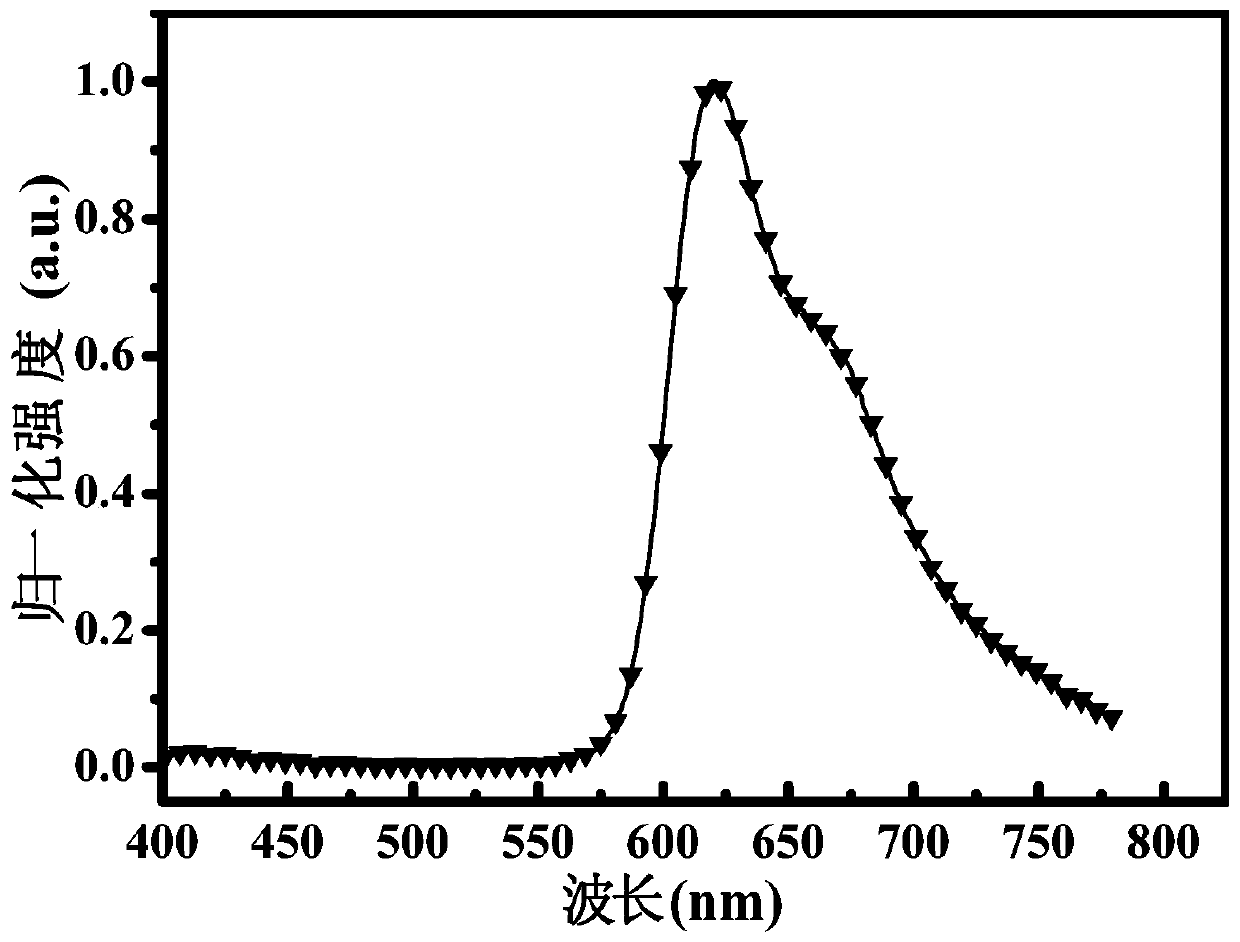

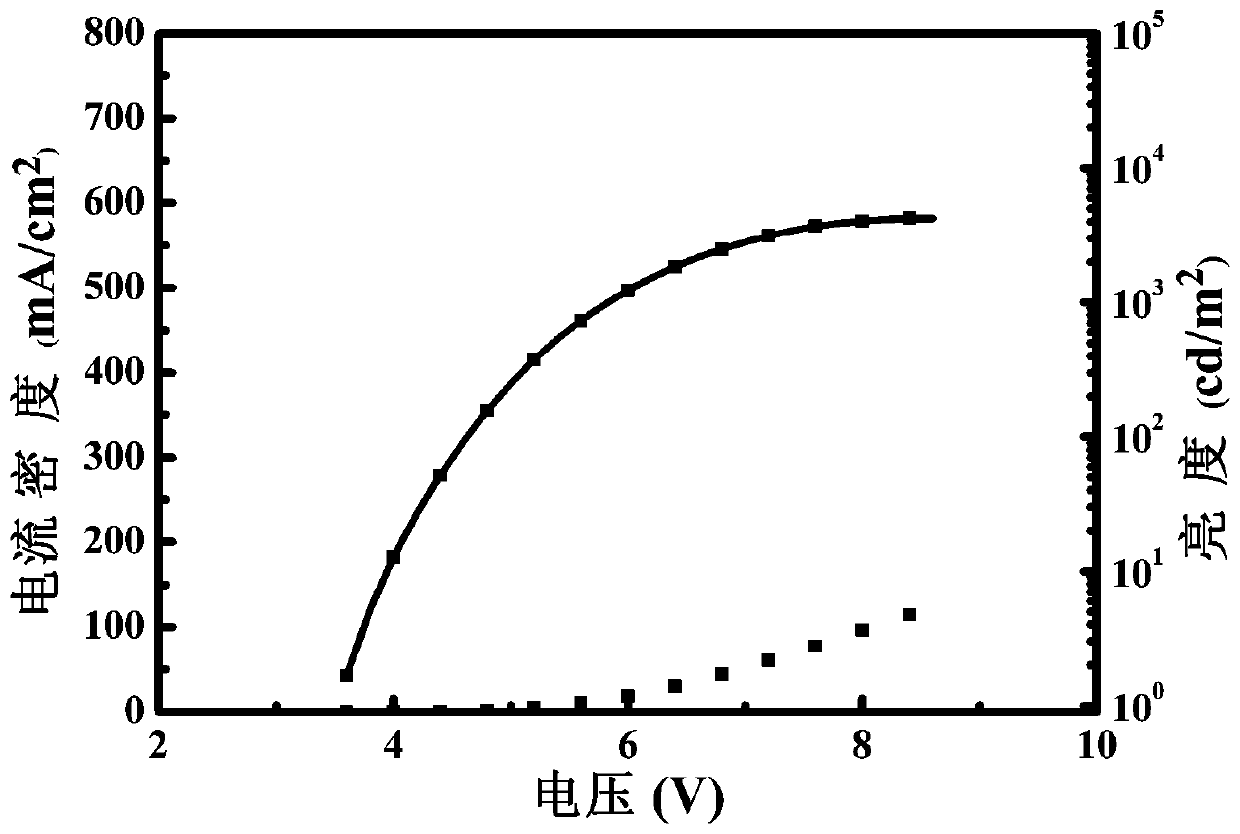

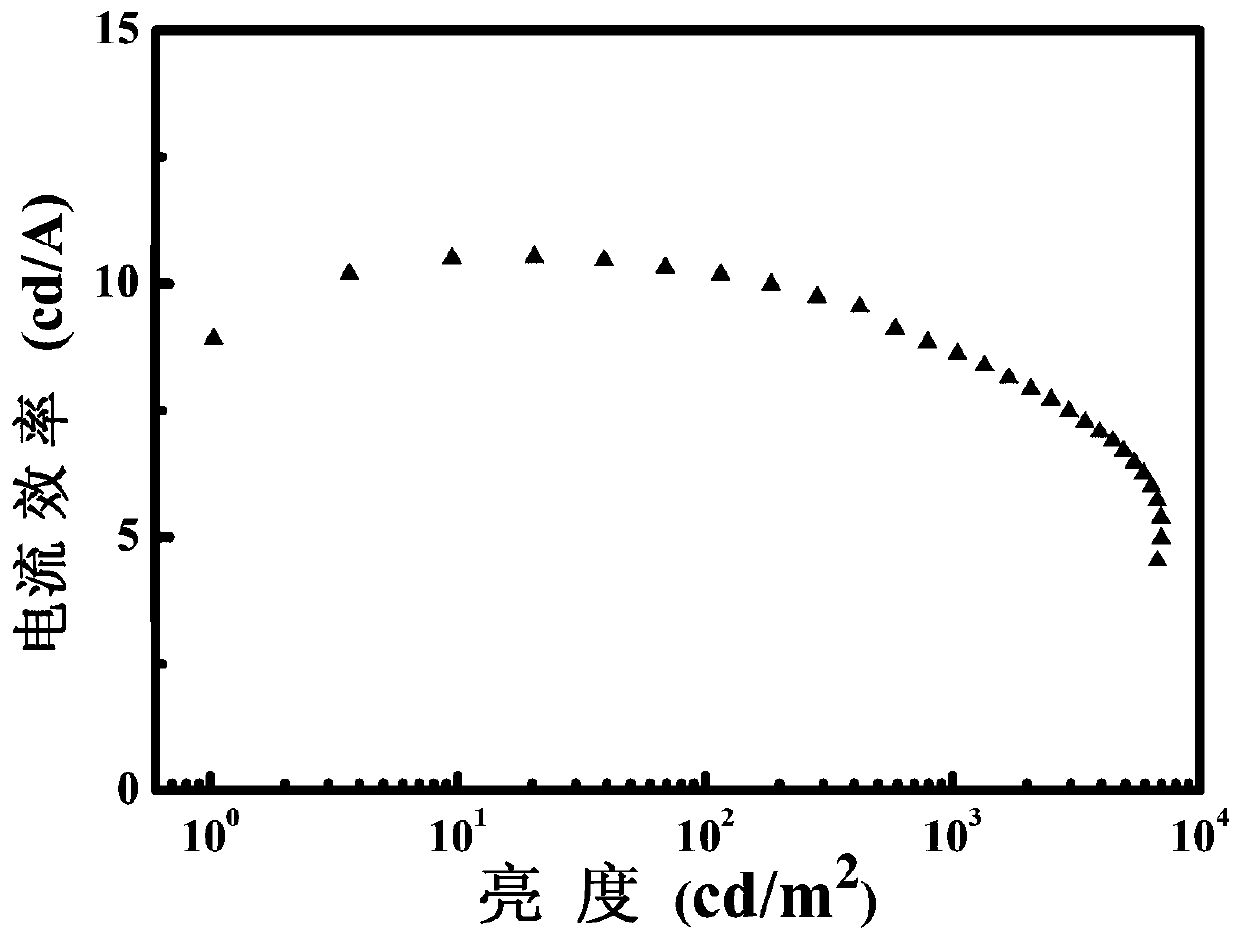

[0089] Example 3 Preparation of iridium complex Samc 8 organic electroluminescent device

[0090] The preparation of the organic electroluminescent device with Samc 8 as the emission center of the luminescent layer is taken as an example to illustrate the preparation of the organic electroluminescent device of the present invention. The structure of OLEDs devices includes: substrate, anode, hole injection material, hole transport layer, organic light emitting layer, electron transport layer, electron injection material and cathode. The substrate is glass, the anode is indium tin oxide, and the hole injection layer is 2,3,6,7,10,11-hexacyano-1,4,5,8,9,12-hexaazabenzene Phenanthrene HAT-CN (5nm), the evaporation rate is 0.05nm / s; the hole layer uses 4,4'-cyclohexylbis[N,N-bis(4-methylphenyl)aniline TAPC material (55nm) , The evaporation rate is 0.05nm / s; the electron transport layer uses 1,3,5-tris[(3-pyridyl)-3-phenyl]benzene TmPyPB (55nm), and the evaporation rate is 0.05nm / s; e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com