Surface anti-bacterial structure of substrate used in space environment and preparation method thereof

A technology of substrate surface and space environment, applied in the direction of surface reaction electrolytic coating, vacuum evaporation coating, metal material coating process, etc., can solve the corrosion of titanium and titanium alloy materials, shorten the life of spacecraft, and endanger astronauts Life and other problems, to achieve the effect of enhancing binding force, enhancing microbial corrosion resistance, and slowing down the release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

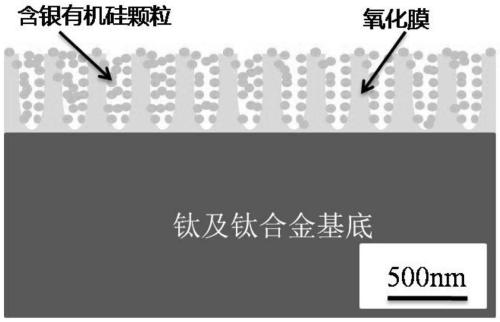

[0028] The preparation method of the silver-containing organosilicon compound particles is as follows: fully mix the organosilicon and silver-containing compound powders with a mixer, and press the mixed powder into a cake with a tablet machine to obtain the organosilicon and silver-containing compound particles. For composite particles of silver compound, the mass ratio of organosilicon to silver-containing compound is 1:0.3-3.

[0029] A method for preparing an antibacterial structure on the surface of a substrate for a space environment, the steps of the method comprising:

[0030] Step 1, polishing the surface of the substrate to a surface roughness R≤0.4 μm;

[0031] Step 2, performing electrochemical degreasing on the surface of the substrate;

[0032] Step 3, acid etching the surface of the substrate;

[0033] Step 4, anodizing the surface of the substrate to obtain titanium dioxide nanotubes on the surface of the substrate;

[0034] Step 5, placing the substrate wit...

Embodiment 1

[0042] The pure titanium and TC4 test pieces are sequentially used with 400 # 、600 # , 800 # 、1000 # , 1200 # , 1500 # , 2000 # Polished with terracotta paper, washed with distilled water. Bind the test piece with titanium wire and place it in sodium hydroxide (30-50) g / L, sodium carbonate (30-50) g / L, trisodium phosphate (20-30) g / L, sodium silicate (3 ~5) In the g / L electrochemical degreasing tank, set the solution temperature to 80°C and the current density to 5A / dm 2 , degreasing time 2min. Take the test piece out of the degreasing tank and rinse its surface with distilled water. Place the sample in the solution formula: 40% hydrofluoric acid 100ml / L, nitric acid 100ml / L mixed acid, soak at room temperature for 60s. Take the test piece out of the mixed acid solution and rinse its surface with distilled water. Place the test piece in a sulfuric acid solution with an electrolyte formula of 180-200g / L, set the solution temperature to -5°C, the oxidation voltage to 8...

Embodiment 2

[0044] The pure titanium and TC4 test pieces are sequentially used with 400 # 、600 # , 800 # 、1000 # , 1200 # , 1500 # , 2000 # Polished with terracotta paper, washed with distilled water. Bind the test piece with titanium wire and place it in sodium hydroxide (30-50) g / L, sodium carbonate (30-50) g / L, trisodium phosphate (20-30) g / L, sodium silicate (3 ~5) In the g / L electrochemical degreasing tank, set the solution temperature to 80°C and the current density to 5A / dm 2 , degreasing time 2min. Take the test piece out of the degreasing tank and rinse its surface with distilled water. Place the sample in the solution formula: 40% hydrofluoric acid 100ml / L, nitric acid 100ml / L mixed acid, soak at room temperature for 60s. Take the test piece out of the mixed acid solution and rinse its surface with distilled water. Place the test piece in a sulfuric acid solution with an electrolyte formula of 180-200g / L, set the solution temperature to -5°C, the oxidation voltage to 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Colony count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com