Recycling method of waste nickel cobalt manganese lithium ternary battery positive electrode material

A technology of nickel-cobalt lithium manganate and ternary battery, which is applied in the field of recycling and utilization of waste nickel-cobalt lithium manganate ternary battery cathode materials, can solve problems such as difficulty in enlarging production and filtering, and achieves reduction of production cost, improvement of recovery rate, Realize the effect of resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

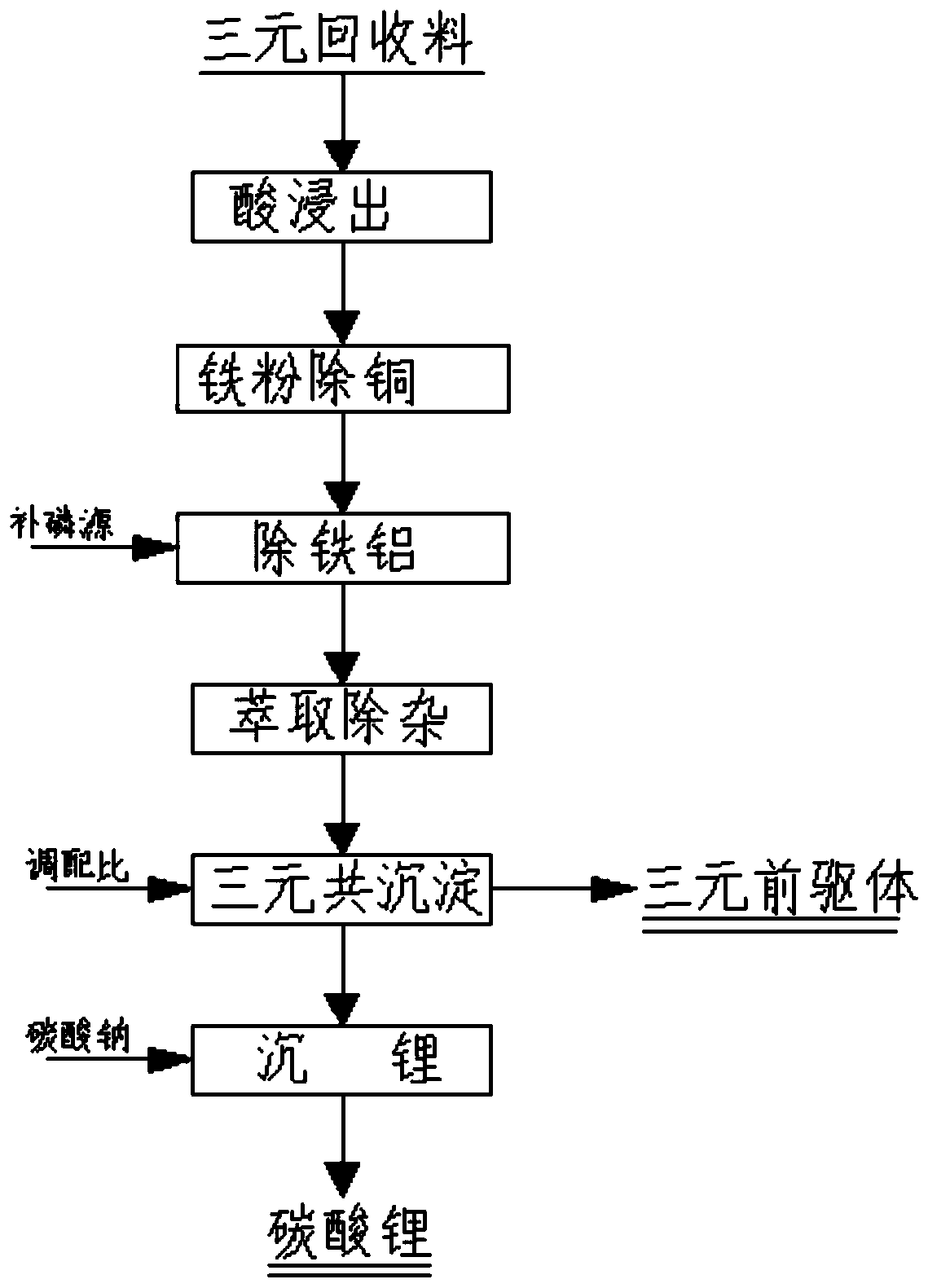

Method used

Image

Examples

Embodiment 1

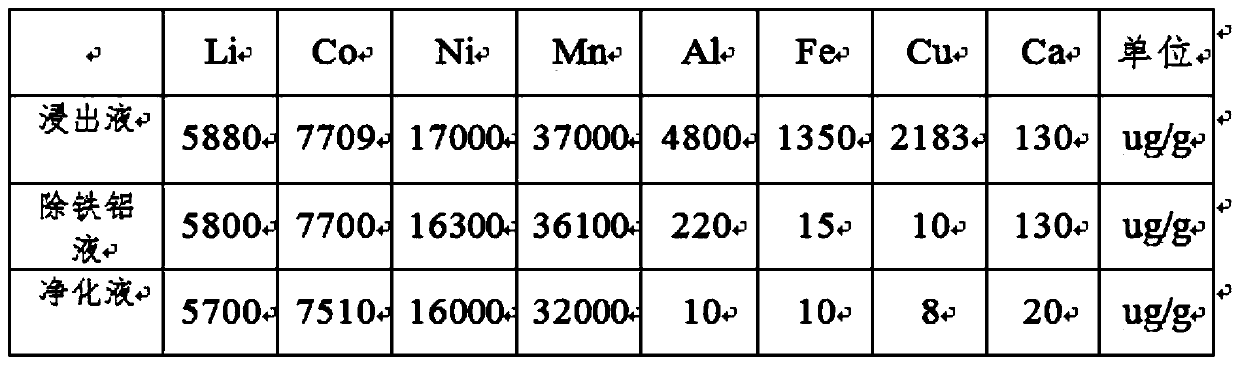

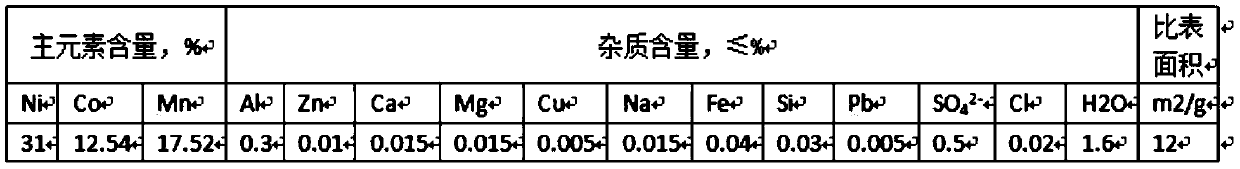

[0031] Take 25g of ternary powder, add it into 80ml of 0.25mol / L dilute sulfuric acid solution, stir at 200-800r / min, add hydrogen peroxide drop by drop, react for 2h and filter to obtain leachate. The analysis results of the leachate are shown in Table 1; g iron powder, stirred and reacted at 50 degrees for 30 minutes, filtered to obtain the copper-removed liquid; the copper-removed liquid was added with 6g of 85% phosphoric acid, stirred and slowly added dropwise 6ml of industrial hydrogen peroxide, the reaction temperature was 45 degrees, and the dripping time was 60min; Add 1mol / L sodium hydroxide at this temperature to adjust the pH to 3, and the reaction time is 30min. Filter the iron-aluminum slag to obtain the iron-removing aluminum liquid. The content analysis results are shown in Table 1; add 30ml of P204 with a saponification rate of 65% to the iron-removing aluminum liquid. , control the water phase equilibrium pH=2.8, obtain purification solution after 3 stages of ...

Embodiment 2

[0033]Take 25g of ternary powder, add it to 120ml 0.5mol / L dilute hydrochloric acid solution, stir at 200-800r / min, add 10ml 1mol / L sodium sulfite solution to react for 2.5h, then filter to obtain leachate; add 1g iron powder to the leachate, Stir and react at 60°C for 20min, filter to obtain the solution after copper removal; add 15ml of 30wt% diammonium hydrogen phosphate solution to the solution after copper removal, stir and slowly add 6ml of industrial hydrogen peroxide dropwise, the reaction temperature is 50°C, and the dripping time is 90min; Add 1mol / L sodium carbonate solution at this temperature to adjust the pH to 2.8, and the reaction time is 60min. Filter the iron-aluminum slag to obtain the iron-removing aluminum solution; add 40ml of P204 with a saponification rate of 70% to the iron-removing aluminum solution to control the equilibrium pH of the water phase= 2.5, the purification solution is obtained after three-stage countercurrent extraction; add appropriate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com