Waterborne polyurethane resin, waterborne polyurethane coating material and preparation method of waterborne polyurethane resin

A technology of water-based polyurethane and resin, applied in the direction of coating, etc., can solve the problems of difficult dissolution and uniform dispersion of nano-silica, unsuitable hardness, scratch resistance, and influence on the permeability of paint film, etc., to achieve convenient and excellent construction The effect of temperature resistance and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

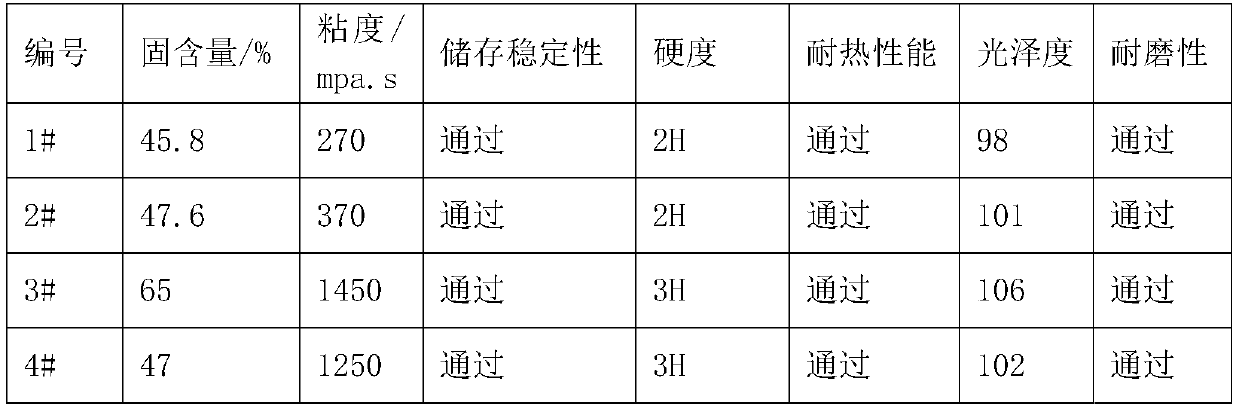

Examples

Embodiment 1

[0046] The preparation method of modified chain extender is as follows:

[0047] Accurately weigh 400g of glycidyl methacrylate, 4.5g of tetrabutylammonium bromide, and 0.03g of hydroquinone in a four-necked flask with a reflux device, and heat up to 120°C while stirring, and dropwise add 270g of dimethylol Propionic acid and 300g N,N-dimethylformamide mixed solution, after 1 hour of dropwise addition, continue to keep warm at 120°C for 9 hours, raise the temperature to 160°C, and distill off N,N-dimethylformamide under reduced pressure , the catalyst tetrabutylammonium bromide and the residual low-molecular monomer, cooling to room temperature, and filtering to obtain a modified chain extender.

[0048] In addition, the preparation of unsaturated polyester polyol is as follows:

[0049] Add 1mol of itaconic acid and 1.2mol of 1,4-butanediol into a four-necked flask, add 1.5g of stannous chloride and 0.5g of hydroquinone and raise the temperature to 160°C for esterification r...

Embodiment 2

[0051] The preparation method of waterborne polyurethane resin is as follows:

[0052] The unsaturated polyester polyol prepared by 75g embodiment 1, 100g polyester polyol (polyester polyol based on adipic acid, ethylene glycol, diethylene glycol, model PE-1280S, hydroxyl value 79-86 , molecular weight is 1200, Zhejiang Huafon New Materials Co., Ltd.), 40g polyethylene glycol diacrylate (molecular weight 200, from Dongguan Jiumao Industrial Co., Ltd.) vacuum dehydration, add 150g TDI, 60g acetone to react at 65 ° C 2h, take a sample to detect that the NCO content is 2.82g / 100g (the determination of NCO content refers to GB / T29493.6-2013), add dropwise a mixture of 15g dimethylolpropionic acid and 30g N,N-dimethylformamide and 20g The modified chain extender prepared in Example 1 was dropped within 0.5 hours, kept for 1.5 hours, added 2.5g of AIBN, heated to 80°C, slowly added dropwise 25g of vinyl silicone oil (vinyl content 3.1%, kinematic viscosity 100mm 2 / s, from Anhui A...

Embodiment 3

[0054] The preparation method of waterborne polyurethane resin is as follows:

[0055] The unsaturated polyester polyol that 60g embodiment 1 prepares, 120g saturated polyester polyol (the polyester polyol based on adipic acid, diethylene glycol, 1,4-butanediol, PE-2348, hydroxyl value 45-50, the molecular weight is 2350, Zhejiang Huafeng New Material Co., Ltd.), 60g of polyethylene glycol (400) diacrylate (from Dongguan Jiumao Industrial Co., Ltd.) vacuum dehydration at 110 ° C for 2 hours, Cool down to room temperature, add 180g of diphenylmethane diisocyanate (MDI) and 120g of acetone, raise the temperature to 68°C, react for 1.5 hours, and take a sample to detect that the NCO content is 3.1g / 100g (the determination of the NCO content refers to GB / T 29493.6-2013 ), dropwise the mixed solution of dimethylolpropionic acid of 17g and 35g of N,N-dimethylformamide and the modified chain extender prepared in 25g embodiment 1, dropwise finished in 0.5 hour, heat preservation react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com