Preparation method of quick-drying high-bonding-strength ceramic tile adhesive

A high-bond, tile adhesive technology, used in polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of long setting time and low bonding strength, and improve lipophilic performance. , improve compatibility, reduce the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

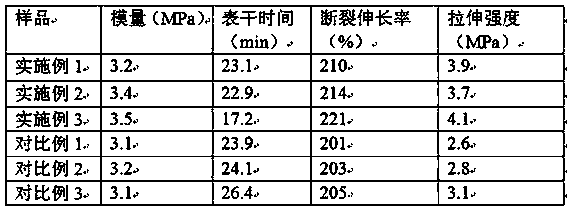

Examples

preparation example Construction

[0039] A preparation method of quick-drying high-bond strength tile adhesive, comprising the steps of:

[0040] (1) Mix carboxymethyl chitosan, guar gum, and 5% acetic acid solution at a mass ratio of 1:2~4:15~25 at 30~45°C, and use a magnetic force of 350~550r / min Stir for 40 to 60 minutes to obtain a mixed glue solution, take the mixed glue solution and add 6 to 10% of the mass of the mixed glue solution as an auxiliary material for mixing, adjust the pH to 4.7 to 5.3 with a HCl solution with a mass fraction of 15%, and obtain a pretreated glue solution for later use ;

[0041] (2) In terms of parts by mass, take 2~5 parts of tetrabutyl titanate, 8~12 parts of absolute ethanol, and 25~35 parts of ammonium chloride solution with a mass fraction of 15% and mix them to obtain a mixed solution. Add modified graphene to the liquid at a weight ratio of 12~25:1~4 and mix it with an ultrasonic oscillator, and ultrasonically treat it at a frequency of 45~55kHz for 12~25min to obtain...

Embodiment 1

[0046] Auxiliary materials: Glycerin and glutaraldehyde are mixed at a weight ratio of 7:3 to obtain auxiliary materials.

[0047] Pretreatment of fly ash: Take fly ash and HCl solution with a mass fraction of 12% according to the mass ratio of 3:18, mix and stir for 30~45min, filter, take the filter residue and add epoxy soybean oil, egg Phospholipids are evenly mixed to obtain pretreated fly ash.

[0048] Additive: Mix sodium dodecylbenzenesulfonate and ammonium chloride at a weight ratio of 1:1 to obtain the additive.

[0049] Modified graphene: Mix and grind graphene, polyvinyl alcohol, and glycerin in a mortar for 1~3 hours according to the mass ratio of 6:1:1 to obtain modified graphene.

[0050] Nutrient base solution: in parts by mass, mix 20 parts of peptone, 6 parts of yeast powder, 0.1 part of potassium chloride, 0.2 parts of magnesium sulfate, 1 part of potassium dihydrogen phosphate, 1 part of casein, and 100 parts of water, and sterilize , that is, the nutrient...

Embodiment 2

[0062] Auxiliary materials: Glycerin and glutaraldehyde are mixed at a weight ratio of 12:3 to obtain auxiliary materials.

[0063] Pretreatment of fly ash: Take fly ash and HCl solution with a mass fraction of 12% according to the mass ratio of 7:18, mix and stir for 45 minutes, filter, take the filter residue and add epoxy soybean oil and lecithin according to the mass ratio of 12:1:1 and mix Evenly, the pretreated fly ash is obtained.

[0064] Additive: Mix sodium dodecylbenzenesulfonate and ammonium chloride at a weight ratio of 1:3 to obtain the additive.

[0065] Modified graphene: Mix and grind graphene, polyvinyl alcohol, and glycerin in a mortar for 1~3 hours according to the mass ratio of 10:1:1 to obtain modified graphene.

[0066] Nutrient base solution: in parts by mass, mix 30 parts of peptone, 10 parts of yeast powder, 0.4 parts of potassium chloride, 0.5 parts of magnesium sulfate, 3 parts of potassium dihydrogen phosphate, 4 parts of casein, and 130 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com