Weak anion chromatography medium, preparation method and application thereof

A chromatographic medium, weak anion technology, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a preparation method of a weak anion chromatography medium, comprising the steps of:

[0025] Dissolving tetrachlorethylene and Span 80 in liquid paraffin to obtain an oil phase;

[0026] mixing allylamine salt, hydroxy methacrylate, N,N-methylenebisacrylamide, porogen, buffer solution with a pH value of 7, and an initiator to obtain an aqueous phase;

[0027] The oil phase and the water phase are mixed, and a copolymerization reaction is carried out under a protective atmosphere to obtain a weak anion chromatographic medium.

[0028] In the present invention, tetrachlorethylene and Span 80 are dissolved in liquid paraffin to obtain an oil phase.

[0029] In the present invention, the mass concentration of tetrachlorethylene in the oil phase is preferably 30-40%, more preferably 36-38%, and the mass concentration of Span 80 is preferably 0.35-0.41%, more preferably 0.41% . The present invention uses tetrachlorethylene to adjust the specific gra...

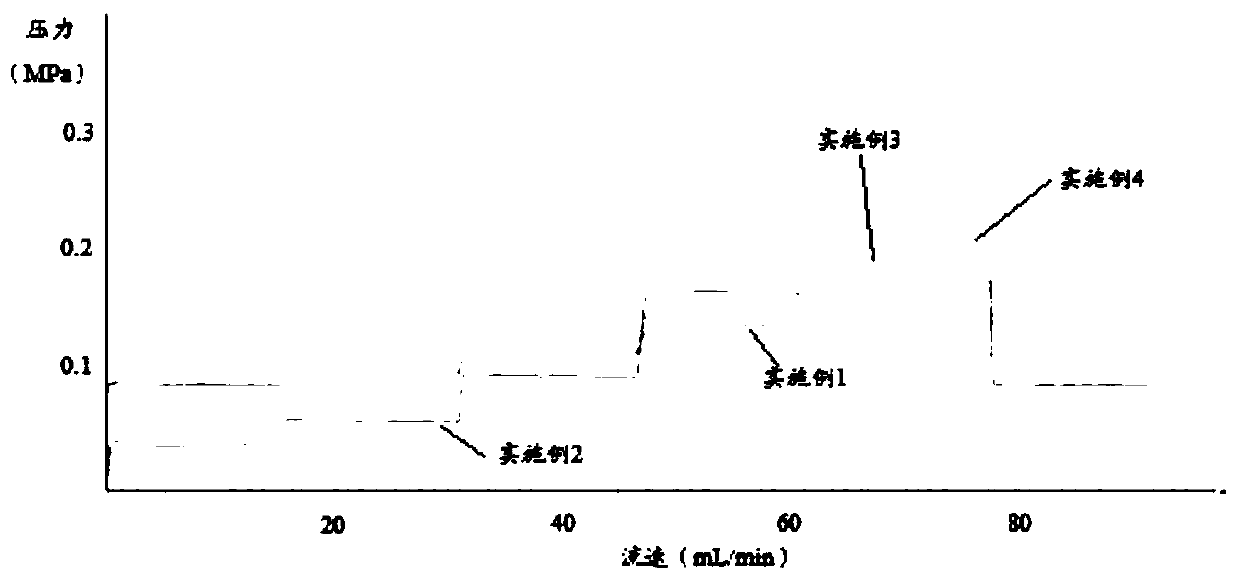

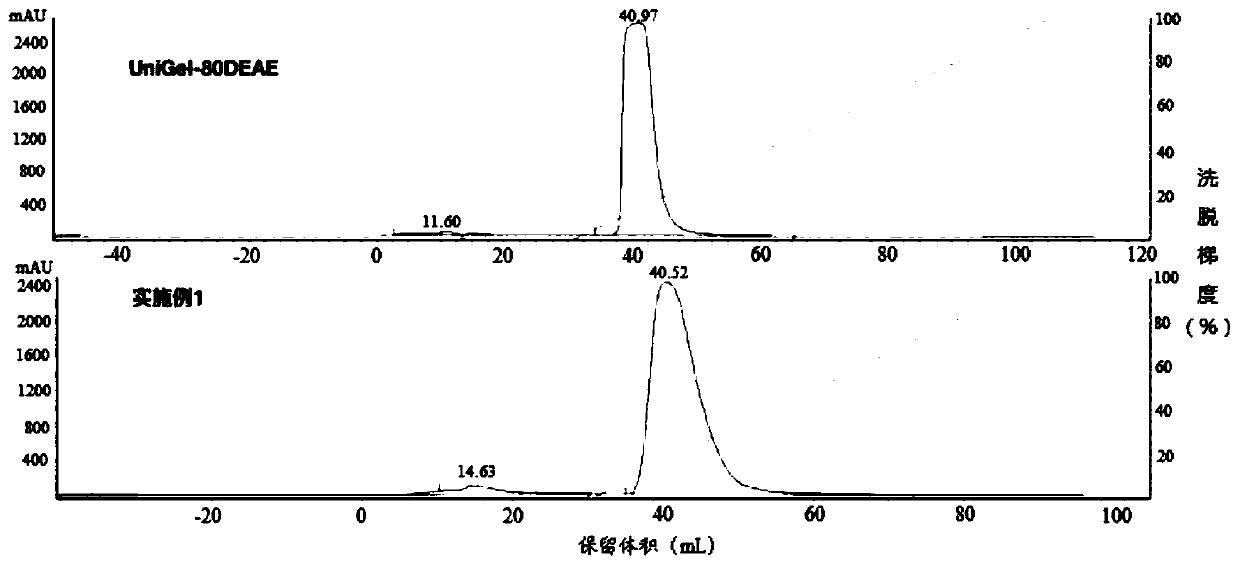

Embodiment 1

[0055] Mix 95g of tetrachlorethylene, 800.9g of Span, and 160g of liquid paraffin, heat up to 70°C, dissolve the solid, and obtain 230mL of oil phase;

[0056] N-methyldiallylamine hydrochloride 6.25g, N,N-methylene bisacrylamide 5.50g, hydroxypropyl methacrylate 2g, ammonium sulfate 1.5g and ethylene glycol 4g and the pH value 7 buffer solution (in which the concentration of sodium phosphate is 1mol / L, and the concentration of hydrogen chloride is 2mol / L) 18g is mixed and heated to 70°C. After the solid is dissolved, add 45mg of 4,4-azobiscyanovaleric acid, After 4,4-azobiscyanovaleric acid is completely dissolved, 39.3mL of water phase is obtained;

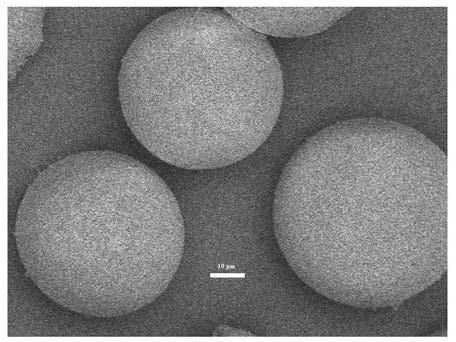

[0057] Mix the water phase and the oil phase, under stirring conditions, maintain the particle size of the oil phase droplets at 30-150 μm, raise the temperature to 85°C, pass in nitrogen, react at 83-85°C for 2.1h, and then cool to room temperature; The reaction solution cooled to room temperature was filtered, and the obtaine...

Embodiment 2

[0064] Mix 95g of tetrachlorethylene, 800.9g of Span, and 160g of liquid paraffin, heat up to 70°C, dissolve the solid, and obtain 230mL of oil phase;

[0065] 6.13g of diallylamine hydrochloride with a purity of 98%, 4.40g of N,N-methylenebisacrylamide, 2g of hydroxyethyl methacrylate, 1.8g of ammonium sulfate, 4g of ethylene glycol and the pH Mix 23g of 7 buffer solution (in which the concentration of sodium phosphate is 1mol / L and the concentration of hydrogen chloride is 2mol / L) and heat up to 70°C. After the solid dissolves, add 20mg of 4,4-azobiscyanovaleric acid , until the 4,4-azobiscyanovaleric acid is completely dissolved to obtain 40mL of the aqueous phase;

[0066]Mix the water phase and the oil phase, under stirring conditions, maintain the particle size of the oil phase droplets at 30-150 μm, raise the temperature to 85°C, pass in nitrogen, react at 83-85°C for 2.1h, and then cool to room temperature; The reaction solution cooled to room temperature was filtered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Peak area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com