A kind of weak anion chromatography medium and its preparation method and application

A chromatographic medium, weak anion technology, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve problems such as slow polymerization speed, complicated preparation process, and difficulty in preparing weak anion chromatographic media.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a preparation method of a weak anion chromatography medium, comprising the steps of:

[0025] Dissolving tetrachlorethylene and Span 80 in liquid paraffin to obtain an oil phase;

[0026] mixing allylamine salt, hydroxy methacrylate, N,N-methylenebisacrylamide, porogen, buffer solution with a pH value of 7, and an initiator to obtain an aqueous phase;

[0027] The oil phase and the water phase are mixed, and a copolymerization reaction is carried out under a protective atmosphere to obtain a weak anion chromatographic medium.

[0028] In the present invention, tetrachlorethylene and Span 80 are dissolved in liquid paraffin to obtain an oil phase.

[0029] In the present invention, the mass concentration of tetrachlorethylene in the oil phase is preferably 30-40%, more preferably 36-38%, and the mass concentration of Span 80 is preferably 0.35-0.41%, more preferably 0.41% . The present invention uses tetrachlorethylene to adjust the specific gra...

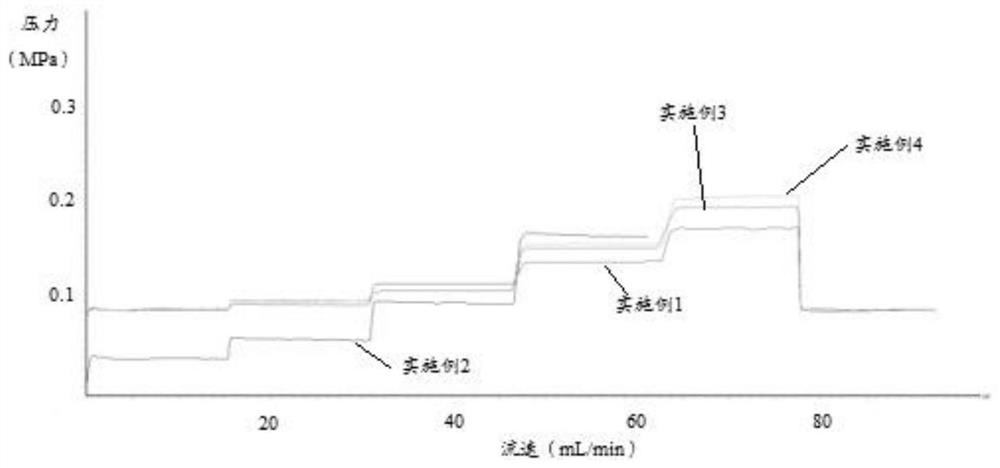

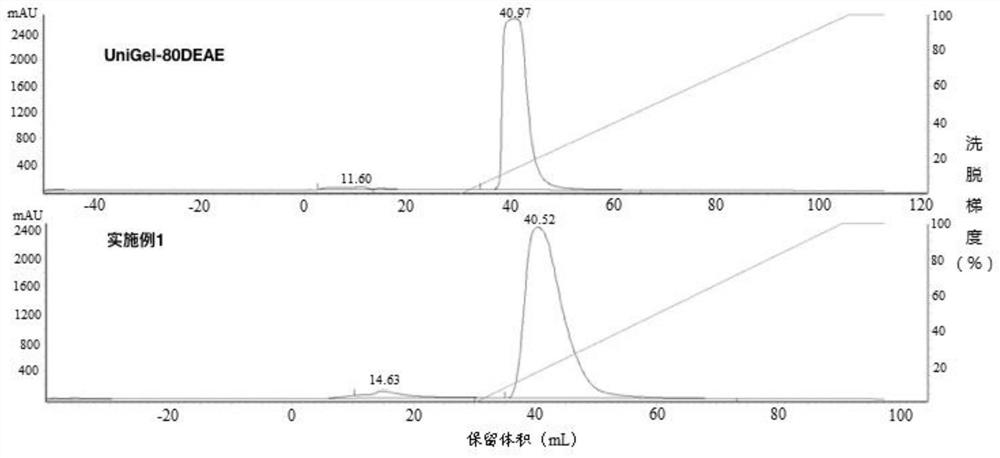

Embodiment 1

[0055] Mix 95g of tetrachlorethylene, 800.9g of Span, and 160g of liquid paraffin, heat up to 70°C, dissolve the solid, and obtain 230mL of oil phase;

[0056] N-methyldiallylamine hydrochloride 6.25g, N,N-methylene bisacrylamide 5.50g, hydroxypropyl methacrylate 2g, ammonium sulfate 1.5g and ethylene glycol 4g and the pH value 7 buffer solution (in which the concentration of sodium phosphate is 1mol / L, and the concentration of hydrogen chloride is 2mol / L) 18g is mixed and heated to 70°C. After the solid is dissolved, add 45mg of 4,4-azobiscyanovaleric acid, After 4,4-azobiscyanovaleric acid is completely dissolved, 39.3mL of water phase is obtained;

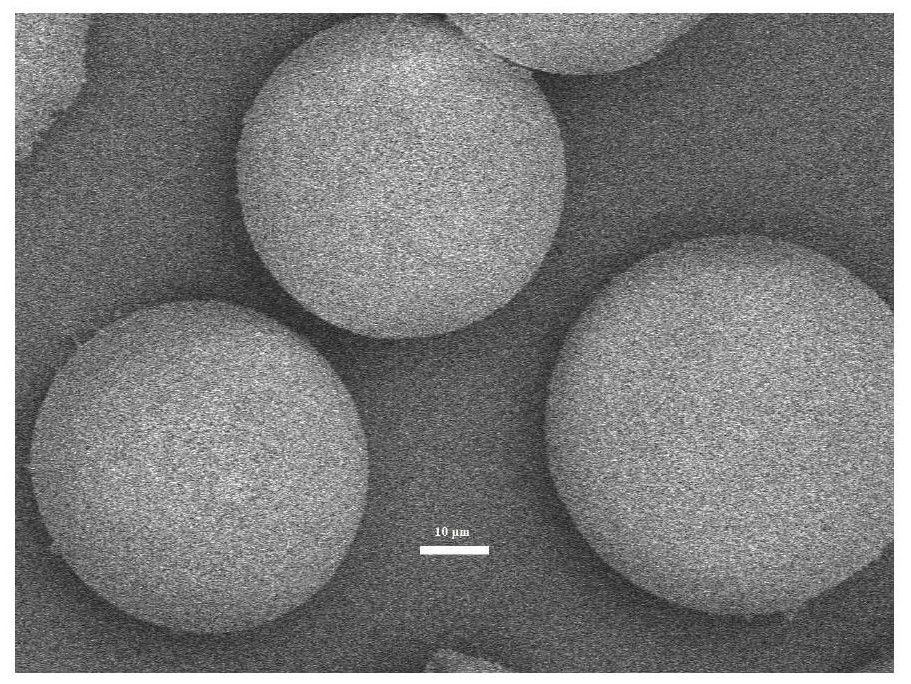

[0057] Mix the water phase and the oil phase, under stirring conditions, maintain the particle size of the oil phase droplets at 30-150 μm, raise the temperature to 85°C, pass in nitrogen, react at 83-85°C for 2.1h, and then cool to room temperature; The reaction solution cooled to room temperature was filtered, and the obtaine...

Embodiment 2

[0064] Mix 95g of tetrachlorethylene, 800.9g of Span, and 160g of liquid paraffin, heat up to 70°C, dissolve the solid, and obtain 230mL of oil phase;

[0065] 6.13g of diallylamine hydrochloride with a purity of 98%, 4.40g of N,N-methylenebisacrylamide, 2g of hydroxyethyl methacrylate, 1.8g of ammonium sulfate, 4g of ethylene glycol and the pH Mix 23g of 7 buffer solution (in which the concentration of sodium phosphate is 1mol / L and the concentration of hydrogen chloride is 2mol / L) and heat up to 70°C. After the solid dissolves, add 20mg of 4,4-azobiscyanovaleric acid , until the 4,4-azobiscyanovaleric acid is completely dissolved to obtain 40mL of the aqueous phase;

[0066]Mix the water phase and the oil phase, under stirring conditions, maintain the particle size of the oil phase droplets at 30-150 μm, raise the temperature to 85°C, pass in nitrogen, react at 83-85°C for 2.1h, and then cool to room temperature; The reaction solution cooled to room temperature was filtered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com