Soft tissue repair material and its preparation method and application

A technology for repairing materials and soft tissue, which is applied in tissue regeneration, medical science, prosthesis, etc. It can solve the problems of poor color and texture integration, difficult maintenance, and difficult operation of the recipient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

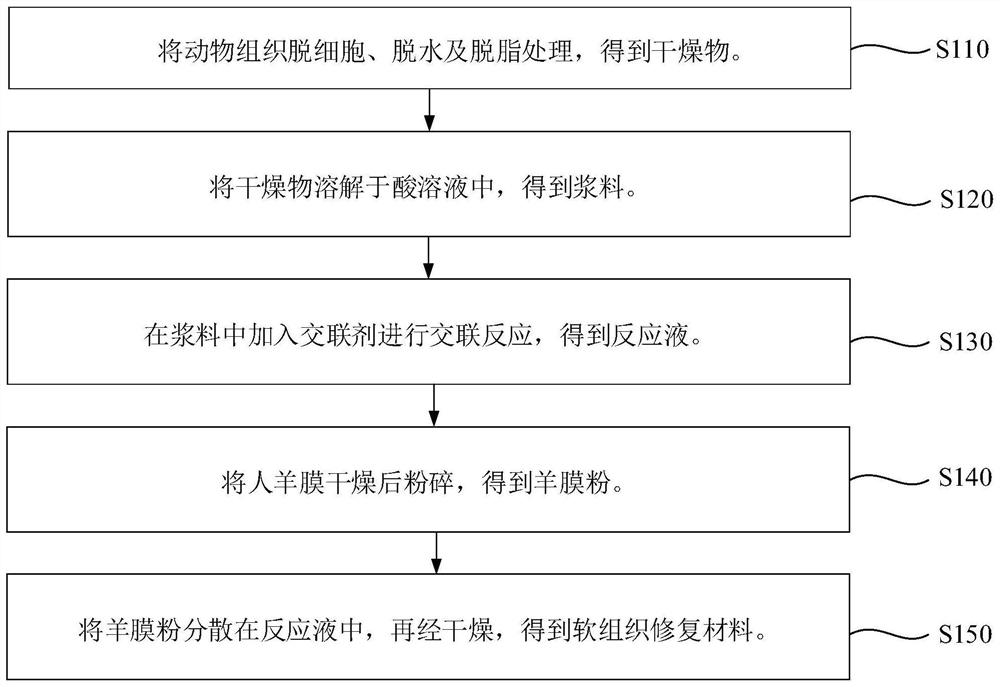

[0031] Such as figure 1 Shown, the preparation method of the soft tissue repair material of one embodiment, comprises the following steps:

[0032] Step S110: Decellularize, dehydrate and degrease the animal tissue to obtain a dry product.

[0033] At this time, the main component of the obtained dried product is collagen fibers.

[0034] Specifically, the steps of decellularizing, dehydrating and degreasing the animal tissue include: alternately washing the animal tissue with a strong alkali solution and a strong acid solution for decellularization, and then using an organic solvent to dehydrate and degrease the washed animal tissue respectively deal with.

[0035] Specifically, the mass percent concentration of the strong alkali solution is 1%-5%. More specifically, the strong alkali solution is selected from at least one of sodium hydroxide aqueous solution and potassium hydroxide aqueous solution.

[0036] Specifically, the mass percent concentration of the strong acid...

Embodiment 1

[0065] The preparation process of the soft tissue repair material of this embodiment is as follows:

[0066] (1) The aqueous solution of potassium hydroxide of 3% and the hydrochloric acid of 0.5% by mass percent concentration are carried out alternate cleaning with the dermal tissue of pig, alternately 2 times; 70%, 80%, 90%, and 100% ethanol for 3 hours each, and then soaked in absolute ethanol for 12 hours to obtain a dry product.

[0067] (2) Grind the dried product obtained in step (1) using a cutting mill, and then sieve it so that the median particle diameter of the dried product is 1 mm to obtain a powdery dried product, and dissolve the powdered dried product at a pH of 3 in the acid solution to obtain a slurry, wherein the dry matter in the slurry has a mass percentage of 7%. Wherein, the acid solution is hydrochloric acid.

[0068] (3) Adding a cross-linking agent to the slurry in step (2) to carry out a cross-linking reaction, and then dialysis to remove the rema...

Embodiment 2

[0073] The preparation process of the soft tissue repair material of this embodiment is as follows:

[0074] (1) The peritoneum of the pig is washed alternately with 1% sodium hydroxide aqueous solution and 1% hydrochloric acid by mass percentage concentration, alternately 4 times; then soaked in 70% mass percentage concentration respectively , 80%, 90% and 100% acetone solutions for 0.5 hours each, and then soaked in acetone for 24 hours to obtain dry matter.

[0075] (2) Grind the dried product obtained in step (1) using a cutting mill, and then sieve it so that the median particle diameter of the dried product is 2mm to obtain a powdered dried product, and the powdered dried product is dissolved in a pH range of 2 in the acid solution to obtain a slurry, wherein the mass percentage of the dry matter in the slurry is 4%. Wherein, the acid solution is acetic acid.

[0076] (3) Adding a cross-linking agent to the slurry in step (2) to carry out a cross-linking reaction, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com