A kind of bipolar visible light detector and preparation method thereof

A visible light detector technology, applied in the field of semiconductor visible light detectors, can solve the problems of difficult fabrication of phototransistor detectors, high dark current of photoconductive detectors, slow light response speed, etc., and achieve low working voltage, fast response speed, The effect of high photoelectric gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

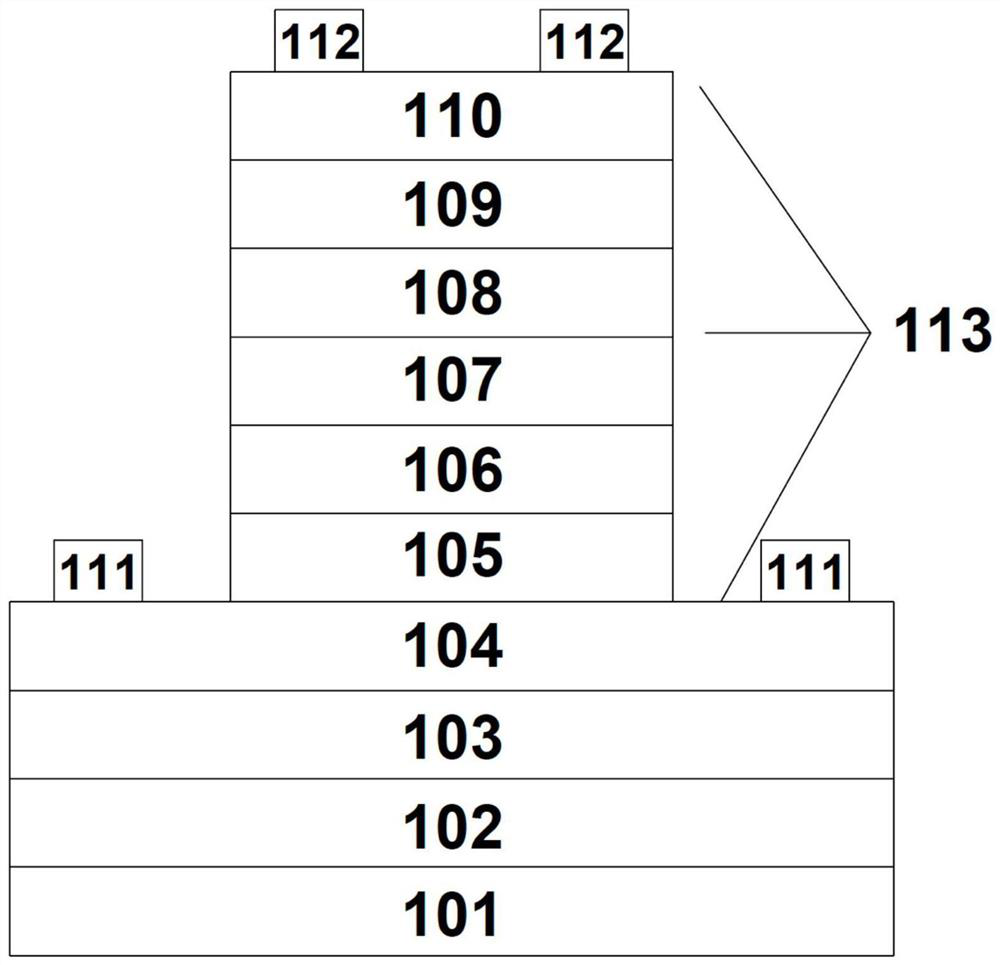

[0030] Such as figure 1 As shown, Embodiment 1 is a schematic structural diagram of a bipolar visible light detector based on Group III nitride semiconductors. The device structure is grown by metal-organic chemical vapor deposition or molecular beam epitaxy, including a c-plane sapphire substrate 101 and an epitaxial layer grown on the substrate 101 . Among them, the order of the epitaxial layer from bottom to top is a 25nm thick low temperature GaN nucleation layer 102, a 3μm thick high temperature unintentionally doped GaN transition layer 103, a 2μm thick electron concentration of 3×10 18 cm -3 The Si-doped n-type GaN lower ohmic contact layer 104 has a thickness of 100 nm and an electron concentration of 3×10 18 cm -3 Al x Ga 1-x N (x start value is 0, end value is 0.15) composition graded layer 105, 5nm thick Al y Ga 1-y N (y=0.15) unintentionally doped layer 106, 110nm thick unintentionally doped Al z Ga 1-z N (start value of z is 0.1, end value is 0) compositi...

Embodiment 2

[0032] This embodiment 2 is a preparation method of a bipolar visible light detector, which specifically includes the following steps:

[0033] S1. Surface cleaning: Place the wafer in acetone and isopropanol in turn, and perform organic cleaning by ultrasonic vibration. After cleaning with deionized water, place the wafer in 50% hydrochloric acid solution to remove the surface oxide layer , blow dry with a pure nitrogen gun;

[0034] S2. Step production: apply glue, photolithography, and develop to expose the part that needs to be etched, and then use inductively coupled plasma to dry etch the wafer to the ohmic contact layer 104 under the Si-doped n-type GaN, and use a glue remover to glue;

[0035] S3. Etching damage repair: treat the wafer with boiled KOH solution, and then use it in high-purity N 2 The rapid thermal annealing process under the atmosphere is annealed at 700 ° C for 1 min;

[0036] S4. Electrode production: glue coating, photolithography, and development...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com