Normal-temperature cured phosphate anticorrosive coating capable of removing formaldehyde through visible light catalysis and achieving sterilization and mildew prevention, and preparation method thereof

A room temperature curing, anti-corrosion coating technology, applied in the direction of anti-corrosion coatings, coatings, paints containing biocides, etc., can solve the problems of air pollution, human health hazards, etc., to achieve enhanced electronegativity, long-lasting sterilization, and easy absorption of electrons Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

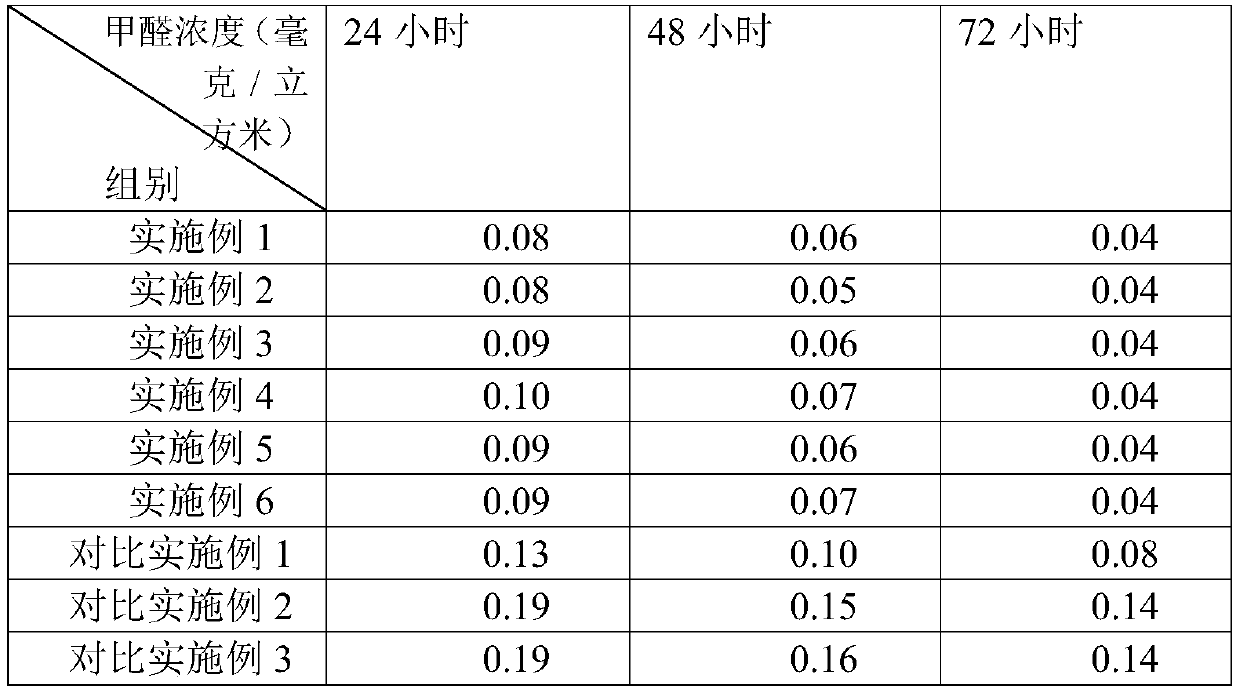

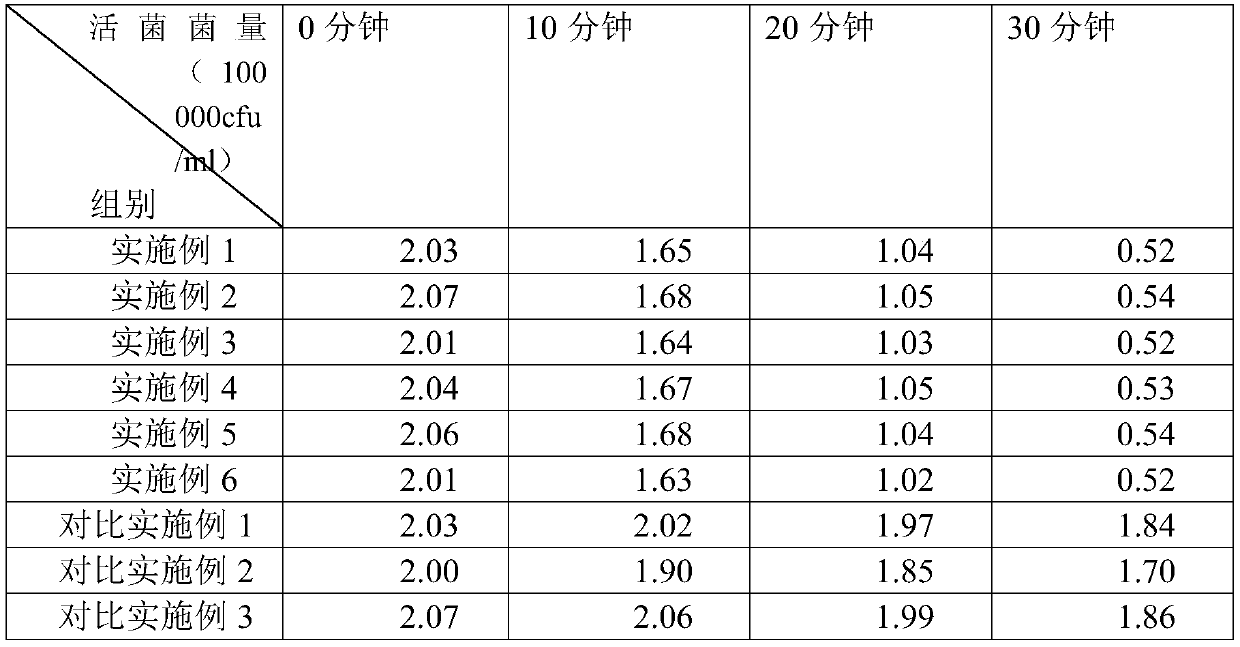

Examples

Embodiment 1

[0029] A normal temperature curing phosphate anti-corrosion coating that catalyzes the removal of formaldehyde with visible light and is sterilizing and anti-mildew, comprising the following components: 30 parts of potassium dihydrogen phosphate, 20 parts of magnesium oxide, 5 parts of aluminum oxide, 2 parts of zinc dioxide, and 2 parts of zirconium oxide 5 parts of potassium silicate, 5 parts of sodium silicate, 10 parts of titanium tetrachloride, 10 parts of sodium hydroxide, 5 parts of copper acetate, 5 parts of zinc acetate, fumed silica (spherical particles with a particle size of 7-40nm ) 8 parts, 2 parts of silica gel, 2 parts of sodium tetraborate, 90 parts of water.

[0030] A method for preparing a visible light catalyzed formaldehyde removal and bactericidal and mildew-proof normal temperature curing phosphate anti-corrosion coating, comprising the following steps:

[0031] 1) Preparation of phosphate colloid: 30 parts of potassium dihydrogen phosphate, 5 parts of ...

Embodiment 2

[0039] A visible light catalyzed removal of formaldehyde and bactericidal, anti-mildew and anti-corrosion coating, comprising the following components: 25 parts of sodium dihydrogen phosphate, 20 parts of magnesium oxide, 3 parts of aluminum oxide, 2 parts of zirconium oxide, 5 parts of potassium silicate, calcium silicate 5 parts, 10 parts of titanium sulfate, 10 parts of potassium hydroxide, 5 parts of copper acetate, 6 parts of fumed silica (spherical particle size is 7-40nm), 2 parts of silica gel, 2 parts of potassium tetraborate, 60 parts of water share.

[0040] A method for preparing formaldehyde-removing catalyzed by visible light and a bactericidal, anti-mildew and anti-corrosion coating, comprising the following steps:

[0041] 1) Preparation of phosphate colloid: 25 parts of sodium dihydrogen phosphate, 5 parts of potassium silicate, 5 parts of calcium silicate, 10 parts of titanium sulfate, and 5 parts of copper acetate were fully mixed and stirred, and then 30 pa...

Embodiment 3

[0049] A visible light catalyzed removal of formaldehyde and bactericidal anti-mildew anti-corrosion coating, including the following components: 10 parts of potassium monohydrogen phosphate, 20 parts of potassium dihydrogen phosphate, 20 parts of magnesium oxide, 5 parts of aluminum oxide, 3 parts of magnesium hydroxide, 2 parts of zirconium, 5 parts of potassium silicate, 5 parts of magnesium silicate, 5 parts of aluminum silicate, 10 parts of butyl titanate, 10 parts of ammonia water, 5 parts of sodium carbonate, 5 parts of zinc acetate, 5 parts of sodium acetate, gas phase II Silicon oxide (spherical particle size 7-40nm) 8 parts, aluminum silicate 2 parts, potassium metaborate 1 part, sodium metaborate 1 part, water 110 parts.

[0050] A method for preparing formaldehyde-removing catalyzed by visible light and a bactericidal, anti-mildew and anti-corrosion coating, comprising the following steps:

[0051] 1) Preparation of phosphate colloid: 10 parts of potassium monohydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com