Treatment method of ecological farming waste

A technology of ecological breeding and treatment method, which is applied in the field of ecological breeding waste treatment, and can solve the problems of low methane production efficiency, refractory degradation, and limiting the development of energy-based treatment technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The processing method of ecological breeding waste specifically comprises the following steps:

[0061] (1) Solid-liquid separation: After the breeding waste of the ecological breeding beef cattle farm is static for 4 hours, the waste is screened and separated into dry material and waste liquid, wherein the water content of the dry material is controlled at 55%;

[0062] (2) Preparation of starter: activate the strains of Bacillus subtilis, Streptomyces, Actinomyces, Aspergillus niger, Trichoderma reesei, Pseudomonas according to conventional methods, and then expand to the concentration of each thalline 5×10 9 -5×10 10 cfu / mL, then centrifuge and collect the thalli, mix each thalline according to the weight ratio of 2.5:1:2.5:1.5:3:1:2, and obtain the starter;

[0063] (3) Dry material fermentation: Mix the separated dry material with sludge and starter at a weight ratio of 5:2.5:1, adjust the pH of the fermentation system to 7.5, and perform anaerobic fermentation a...

Embodiment 2

[0068] The processing method of ecological breeding waste repeats the steps in embodiment 1, and the difference is only in:

[0069] When performing dry material fermentation and waste liquid fermentation in steps (3) and (4), the anaerobic fermentation is carried out under the action of an external low voltage, and the above external low voltage is specifically 0.9V;

[0070] Step (5) Composting starts from the 4th day when the temperature reaches above 55°C, reaches the highest temperature of 63.2°C for the first time on the 7th day, reaches the highest temperature of 57.8°C for the second time on the 18th day, and reaches the highest temperature of 46.4°C for the third time on the 23rd day °C, during which the temperature is above 55 °C for a total of 9 days, and the time for compost to fully decompose is 36 days.

Embodiment 3

[0072] The processing method of ecological breeding waste repeats the steps in embodiment 2, and the difference is only in:

[0073] Step (3) The dry matter used in the dry material fermentation process also includes the harmless products obtained after the above-mentioned dead farmed animals are subjected to pressurized hydrothermal treatment. The specific pressurized hydrothermal treatment steps are: crushing the dead farmed animals, Then place it in an environment with a temperature of 130°C and a pressure of 400KPa for 60 minutes to obtain a harmless product, and the weight ratio of the above harmless product in the dry matter is 25%;

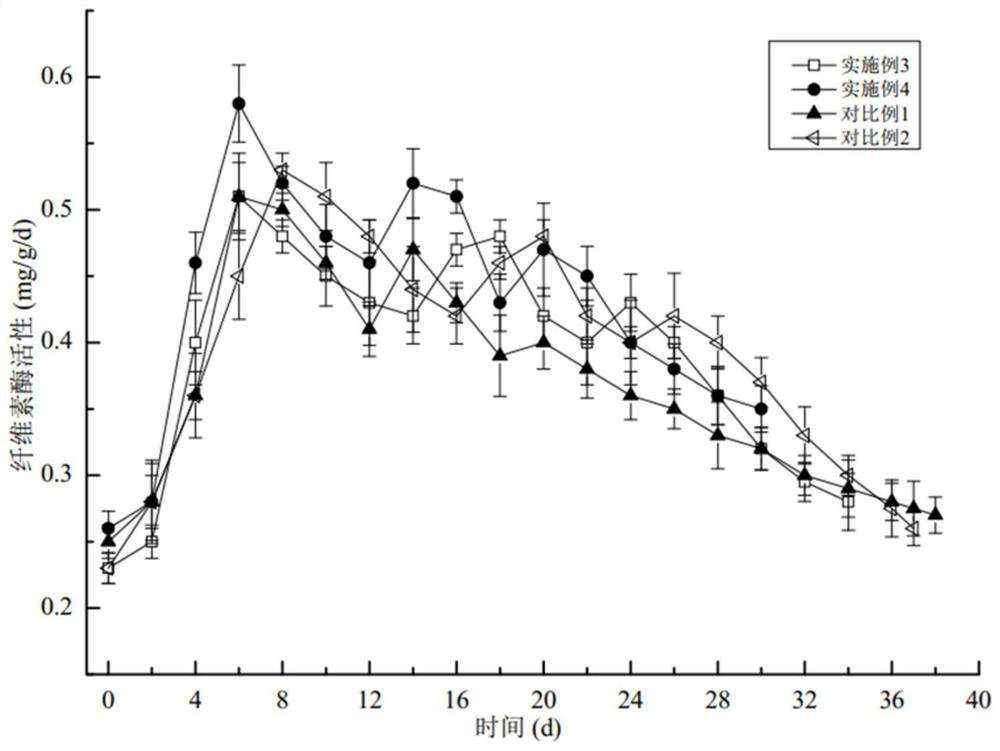

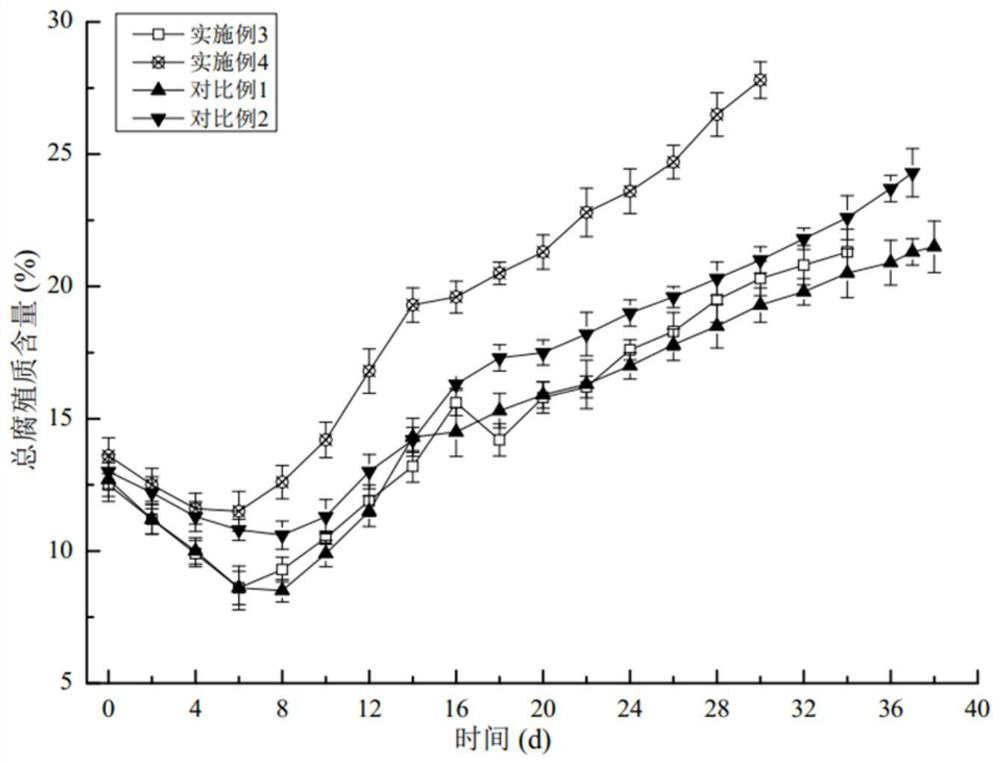

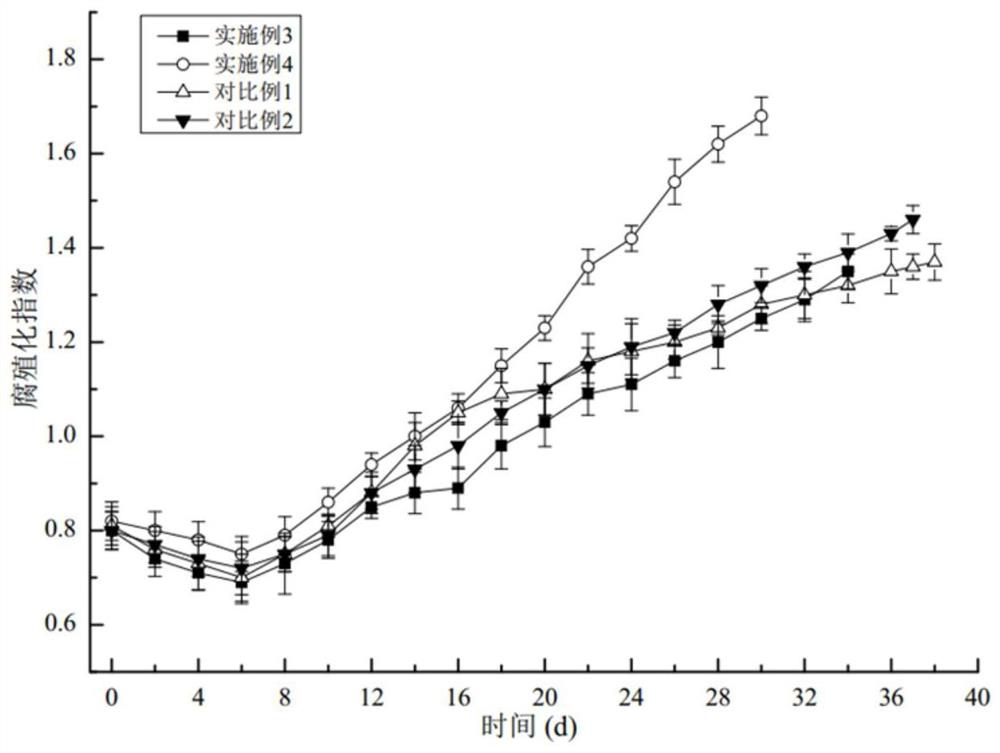

[0074] Step (5) Composting starts at 55°C on the 4th day, reaches the highest temperature of 62.8°C for the first time on the 6th day, reaches the highest temperature of 57.1°C for the second time on the 17th day, and reaches the highest temperature of 44.5°C for the third time on the 24th day °C, during which the temperature is above 55 °C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com