Gold-silver nano cone array with body-enhanced Raman scattering effect as well as preparation method thereof and use thereof

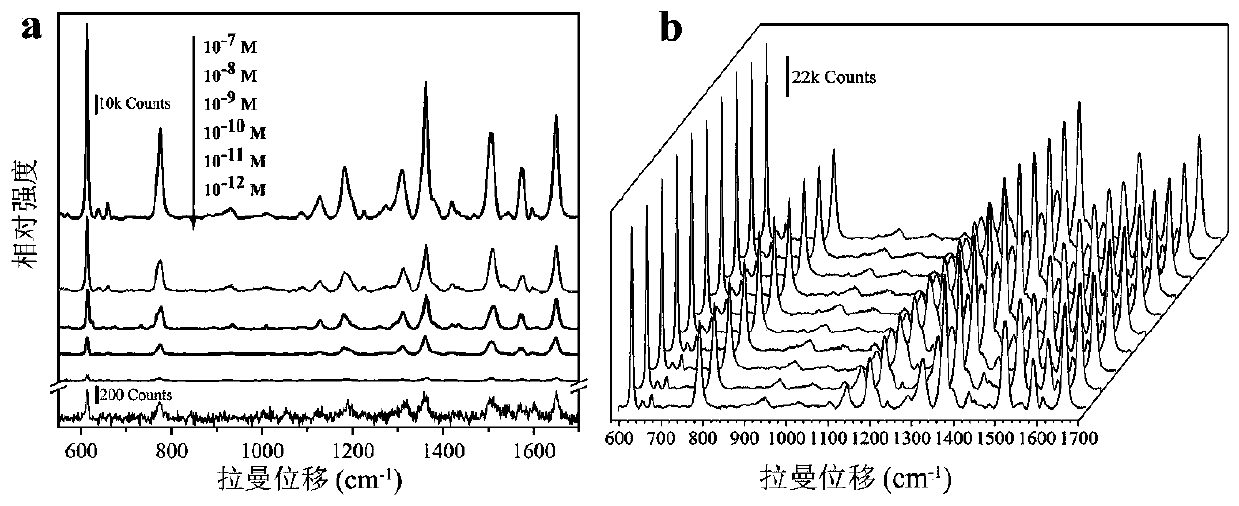

A technology that enhances Raman scattering and silver nanometers. It is applied in Raman scattering, nanotechnology for materials and surface science, and nanotechnology. It can solve the problems of poor product stability, complicated preparation process, and poor uniformity. The method is simple, the signal repeatability is good, and the structure is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

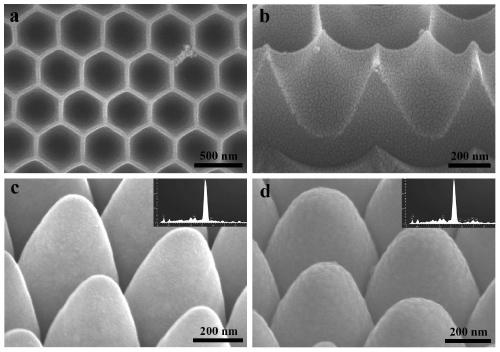

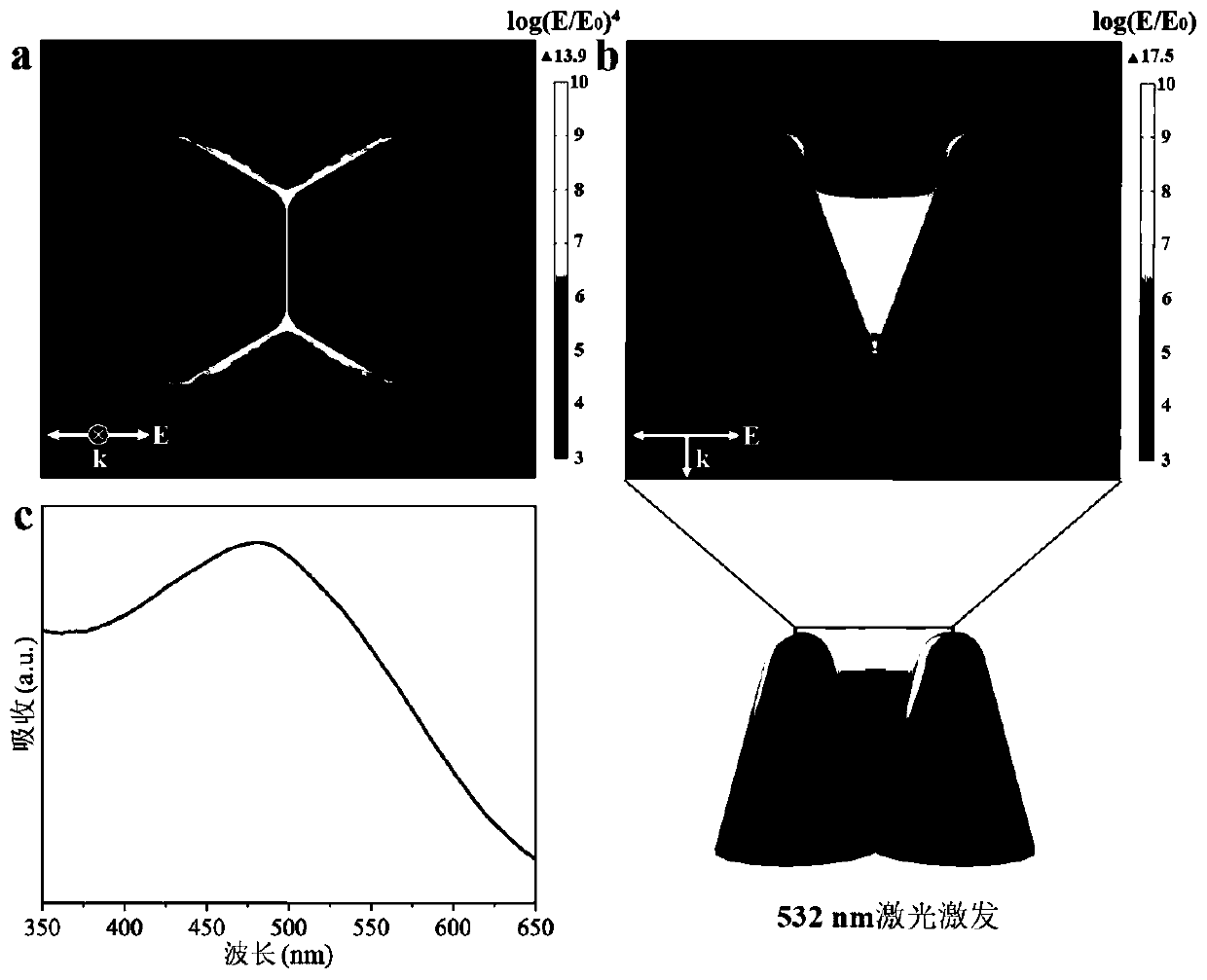

[0047] The specific steps of preparation are:

[0048] Step 1. Place the nickel imprint mold of the hexagonal array nano-pillar array with a period of 495nm, a diameter of 105nm and a height of 150nm on the aluminum sheet and place it at 8kN / cm. 2 The aluminum sheet with dents was obtained for 5 minutes under the same pressure. Then, anodize the aluminum sheet with dents for 3min, wet etching, 5min anodization, wet etching and 3min anodization in sequence; among them, the voltage of anodization is 200V, and the temperature of the electrolyte is A mixture of 100:100:2 ethylene glycol, 5wt% citric acid and 85wt% phosphoric acid with a volume ratio of 10°C. The etching solution for wet etching is a 5wt% phosphoric acid solution with a temperature of 45°C. The time is 80 minutes, and the inverted cone-shaped porous alumina template is obtained.

[0049] Step 2: Firstly, vapor-deposit a 70nm thick gold film on the inverted cone-shaped porous alumina template to obtain an inverted cone-...

Embodiment 2

[0052] The specific steps of preparation are:

[0053] Step 1. Place the nickel imprint mold of the hexagonal array nano-pillar array with a period of 498nm, a diameter of 103nm and a height of 163nm on the aluminum sheet, and place it at 9kN / cm. 2 The aluminum sheet with dents was obtained under a pressure of 4.5 min. Then the aluminum sheet with dents was subjected to 3.5min anodization, wet etching, 4.5min anodization, wet etching and 3.5min anodization in sequence; among them, the voltage of the anodization was 200V, and the electrolyte It is a mixture of ethylene glycol, 5wt% citric acid and 85wt% phosphoric acid at a temperature of 10℃ and a volume ratio of 100:100:1.7. The etching solution for wet etching is 5wt% phosphoric acid at a temperature of 48℃ Solution, soaking time is 75min, to obtain inverted cone-shaped porous alumina template.

[0054] In step 2, a gold film with a thickness of 75 nm is vapor-deposited on the inverted cone-shaped porous alumina template to obta...

Embodiment 3

[0057] The specific steps of preparation are:

[0058] Step 1. First, the nickel imprint mold of the hexagonal array nano-pillar array with a period of 500nm, a diameter of 100nm and a height of 175nm is attached to the aluminum sheet and placed at 10kN / cm 2 The aluminum sheet with dents was obtained for 4 minutes under the same pressure. Then, anodize the aluminum sheet with dents for 4 minutes, wet etching, 4 minutes anodization, wet etching, and 4 minutes anodization in sequence; among them, the voltage of anodization is 200V, and the temperature of the electrolyte is A mixture of 100:100:1.3 ethylene glycol, 5wt% citric acid and 85wt% phosphoric acid with a volume ratio of 10℃. The etching solution for wet etching is a 5wt% phosphoric acid solution with a temperature of 50℃. The time is 70 minutes, and the inverted cone-shaped porous alumina template is obtained.

[0059] In step 2, an 80nm thick gold film is vapor-deposited on the inverted cone-shaped porous alumina template ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com