A comprehensive treatment method for seawater or concentrated brine

A comprehensive treatment of concentrated brine technology, applied in seawater treatment, water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problems of limited yield of nanofiltration permeate, low market acceptance, relying on a large number of salt fields, etc. , to achieve the effect of reducing the risk of fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

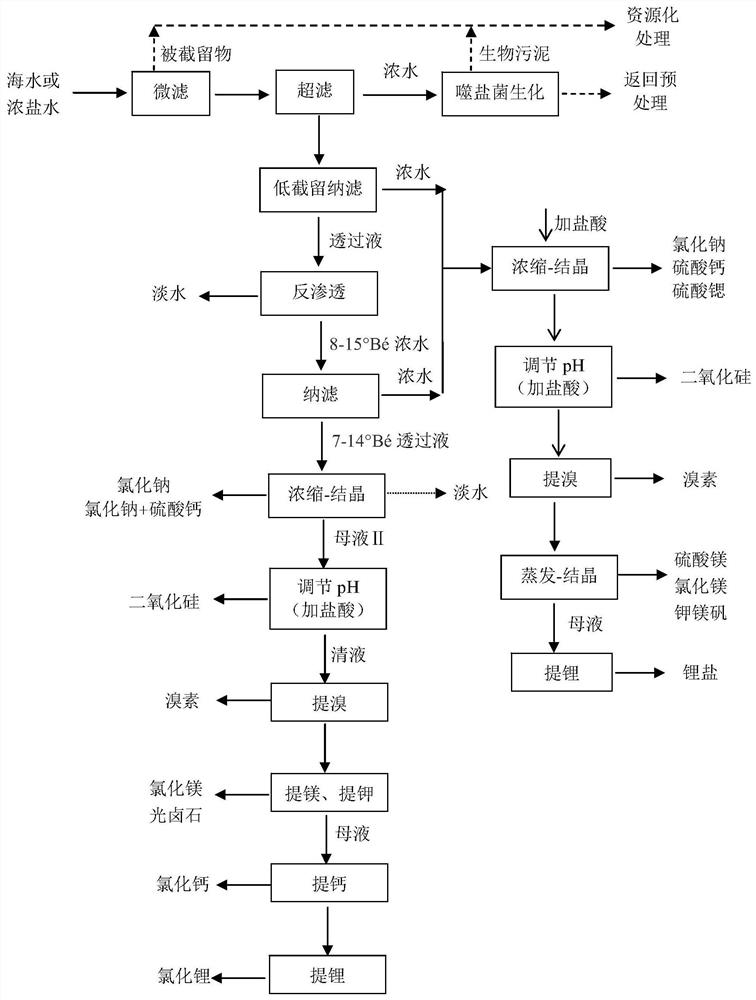

Method used

Image

Examples

Embodiment 1

[0072] Feed liquid: Seawater in a certain area, 3.4°Bé, pH=8.1, the composition is shown in Table 3 below:

[0073] table 3

[0074]

[0075] Pretreatment: Use a polypropylene melt-blown filter with a precision of 5 μm and an ultrafiltration membrane with a molecular weight cut-off of 6000 and 2000, respectively. The overall operating pressure of the microfiltration and ultrafiltration process is 0.25MPa. The microfiltration and ultrafiltration concentrated water enters the sludge resource recovery device for treatment, and the resulting clear liquid is returned to the pretreatment stage.

[0076] Low cut-off nanofiltration process:

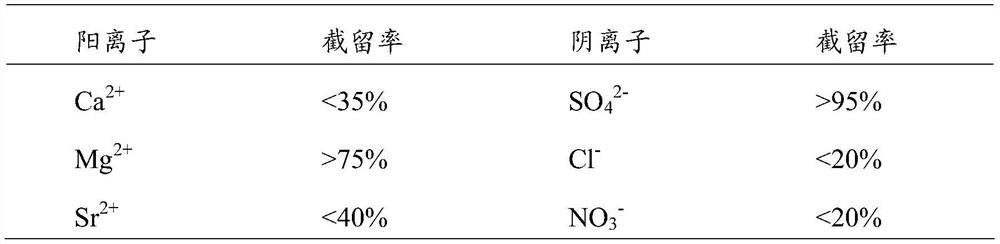

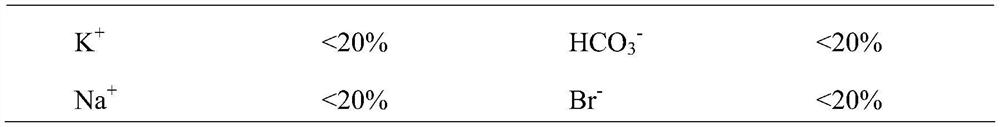

[0077] The pretreated feed liquid enters the low cut-off nanofiltration device (the core membrane element is NF8040 coiled membrane, the performance is shown in Table 1, and the effective area is 30.7m 2 ), operating pressure 1.45MPa, temperature 35°C, pH=8.1. The volume ratio of the nanofiltration permeate 1 obtained after treatment to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com