Aqueous lithium ion battery and application thereof

A lithium-ion battery, water-based technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low capacity retention rate or Coulomb efficiency, rapid capacity decay of water-based lithium-ion batteries, and rapid battery capacity decay, achieving Good Coulombic Efficiency and Capacity Retention, High Coulombic Efficiency and Capacity Retention, Improved Coulombic Efficiency and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

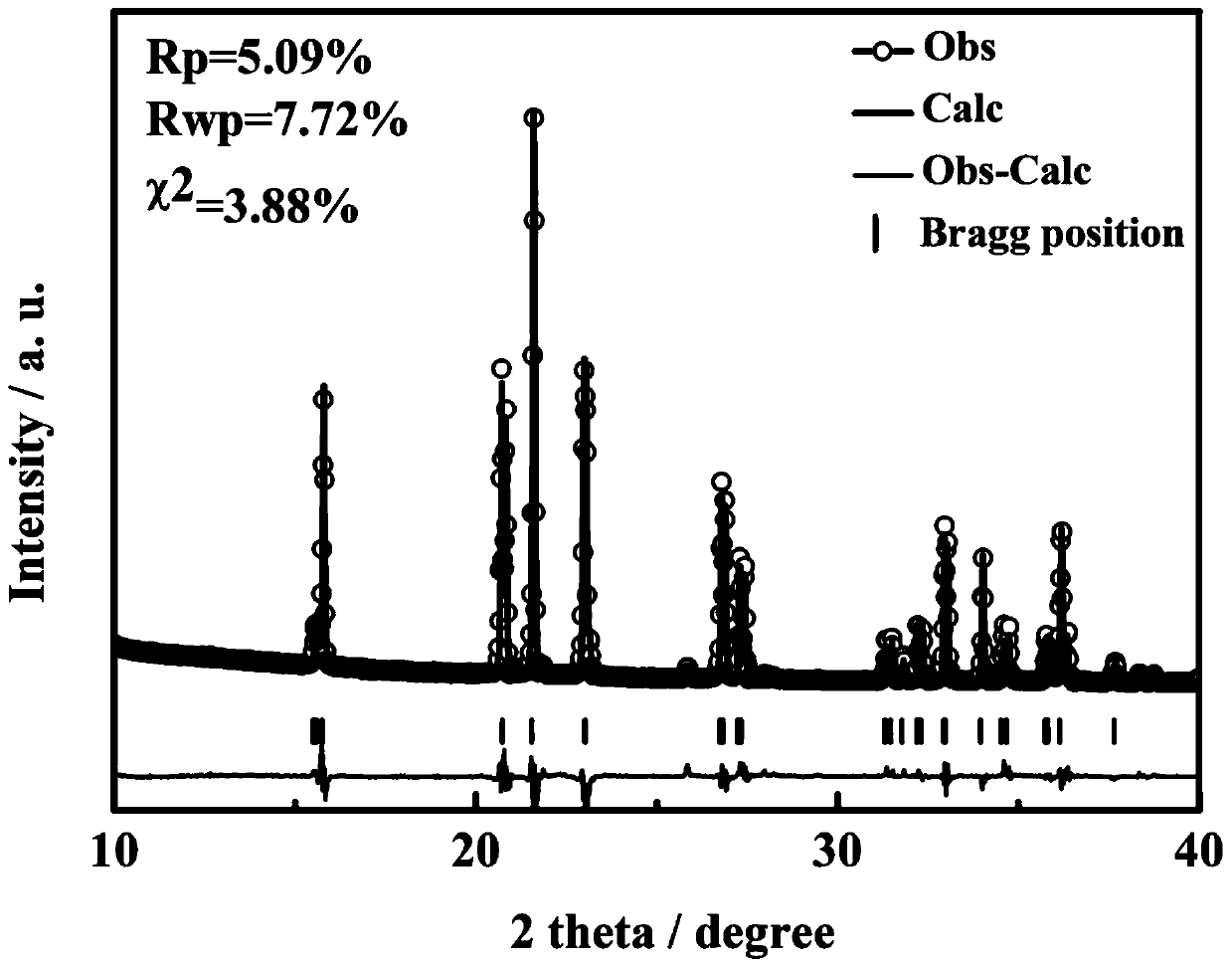

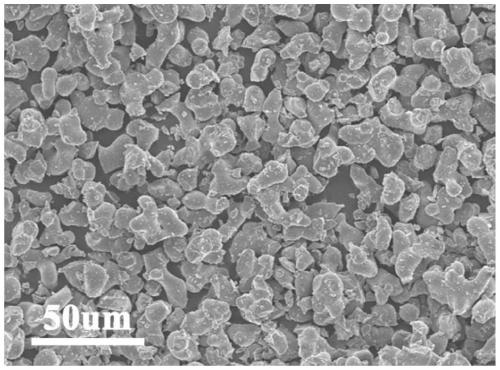

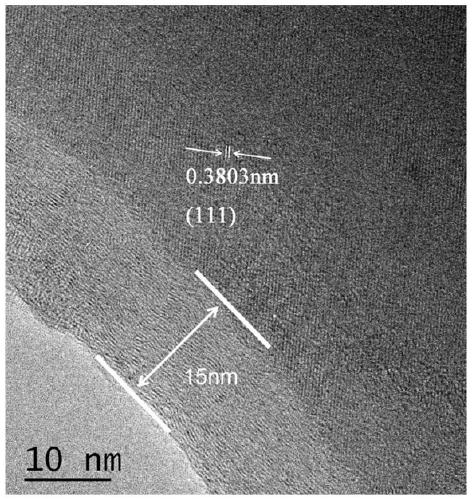

[0068] Weigh 2.658g of niobium pentoxide and 6.902g of ammonium dihydrogen phosphate and disperse them in a ball mill jar containing 20ml of ethanol, rotate at a speed of 400rpm for 8 hours, and dry at 80°C to obtain a powder mixture. Using a crucible, put the powdery mixture into a muffle furnace and raise it to 300° C. at a rate of 1° C. / min, and keep the temperature constant for 3 hours to obtain a precursor. Transfer the precursor into a ball mill and grind at 400rpm for 4 hours, then transfer the uniformly ground powder sample dried at 80°C to a muffle furnace, calcined at 1350°C for 4 hours, and then rapidly quenched in air to obtain white pure NbOPO 4 Material. The resulting NbOPO 4 The material is put into an argon atmosphere reaction furnace, and the reaction furnace is heated at a rate of 5° C. / min. When the temperature rises to 800° C., ethylene gas is fed into the reaction furnace. The atmosphere in the reaction furnace (the volume ratio of ethylene / argon is 5 / 95...

Embodiment 2

[0073] In a weighing bottle, prepare N,N-dimethylacetamide, lithium perchlorate, and water at a molar ratio of 1:0.1~0.8:0.1~2.4, and the state of the obtained mixture is as follows: Figure 4 shown. The experimental results show that the ratio of 0.1~4:1~4:0.1~1 can obtain a uniform ternary electrolyte.

[0074] Using the homogeneous ternary aqueous solution obtained above as the electrolyte, using a three-electrode system, the carbon-coated NbOPO obtained in Example 1 4 as the working electrode, activated carbon as the counter electrode, and Ag / AgCl (saturated KCl) as the reference electrode. Among them, the electrode slurry is prepared according to m (active material): m (polyvinylidene fluoride, PVDF): m (acetylene black) = 75:10:15, and the prepared slurry is coated on the Ti grid, and the positive electrode The mass is about 5-8 mg, and the mass of the negative electrode is 30%-40% more than that of the positive electrode. Put the coated pole pieces into an oven at 80°C...

Embodiment 3

[0079] In a weighing bottle, prepare N,N-dimethylacetamide, lithium perchlorate and water at a molar ratio of 1:0.4:0.4, and obtain a clear ternary solution after magnetic stirring.

[0080] Utilize electrochemical workstation to carry out LSV analysis to the solution that present embodiment 3 obtains, Figure 5 The LSV plot of the resulting ternary solution is shown. Depend on Figure 5 It can be seen that the electrochemical stability window of the obtained ternary solution is as high as above 3V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com