Antibacterial agent and application thereof

A technology of antibacterial agent and solvent, which is applied in the field of antibacterial agent and its application, and can solve the problems of no antibacterial ingredients, no antibacterial function, single antibacterial, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

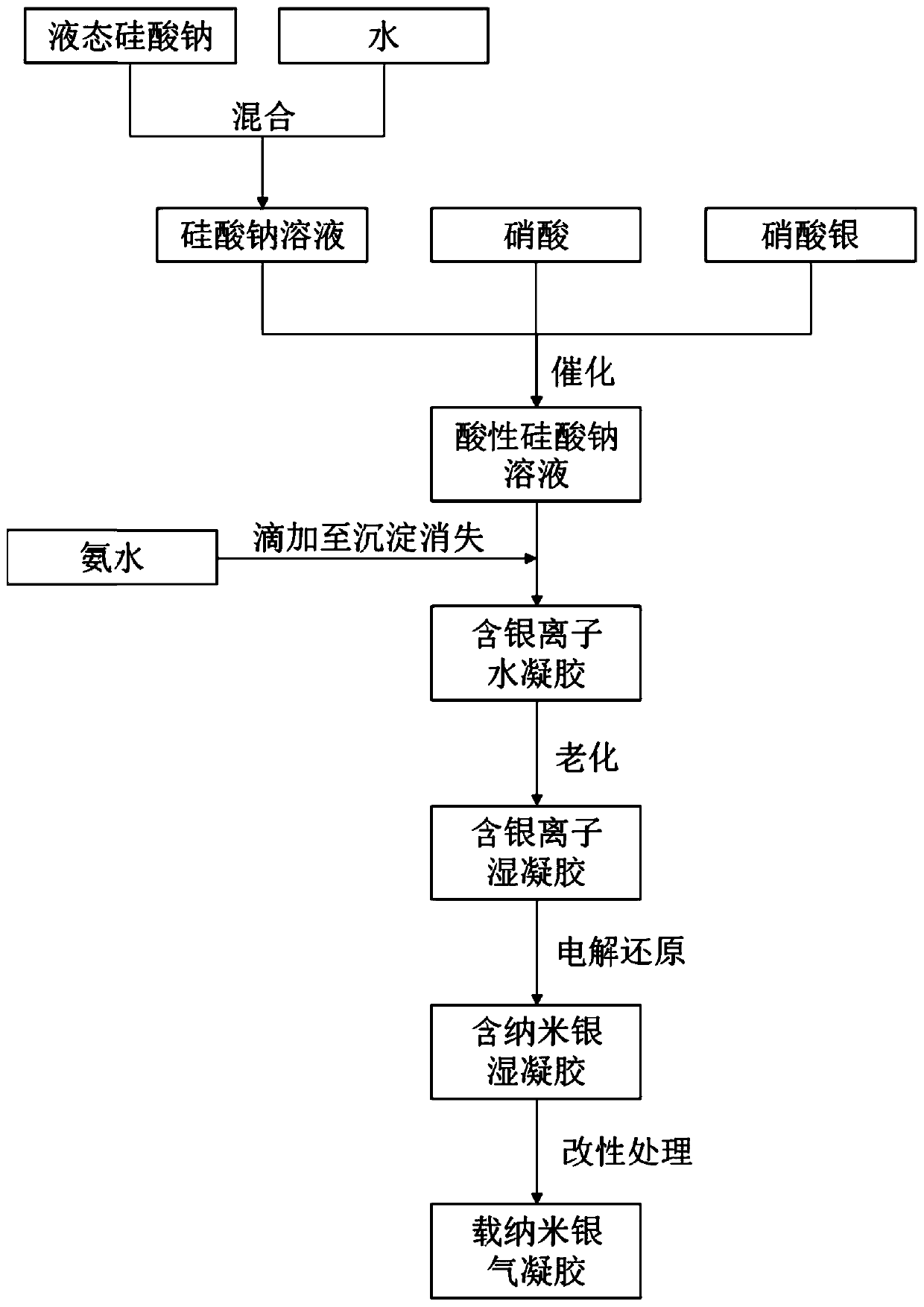

[0072] Refer to attached figure 1 The schematic diagram of the preparation process of antibacterial agent shows that the preparation method of this example antibacterial agent is as follows:

[0073] Weigh the liquid-2 liquid sodium silicate with a modulus of 3.1-3.4, a Baume degree of 39°-41°, and a specific gravity of 1.37-1.40 and deionized water in a ratio of 1:2, and mix evenly to obtain sodium silicate solution.

[0074] A mixed solution containing 0.01mol / L nitric acid and 0.1mol / L silver nitrate was added to the sodium silicate solution at a volume ratio of 1:3, stirred for 15 minutes, and catalyzed to obtain an acidic sodium silicate solution.

[0075] Prepare dilute ammonia water with a concentration of 5%, and add ammonia water dropwise to the acidic sodium silicate solution under stirring conditions until the brown precipitate dissolves, then stop stirring and drop ammonia water, and let it stand for a few minutes to obtain a silver ion-containing water coagulatio...

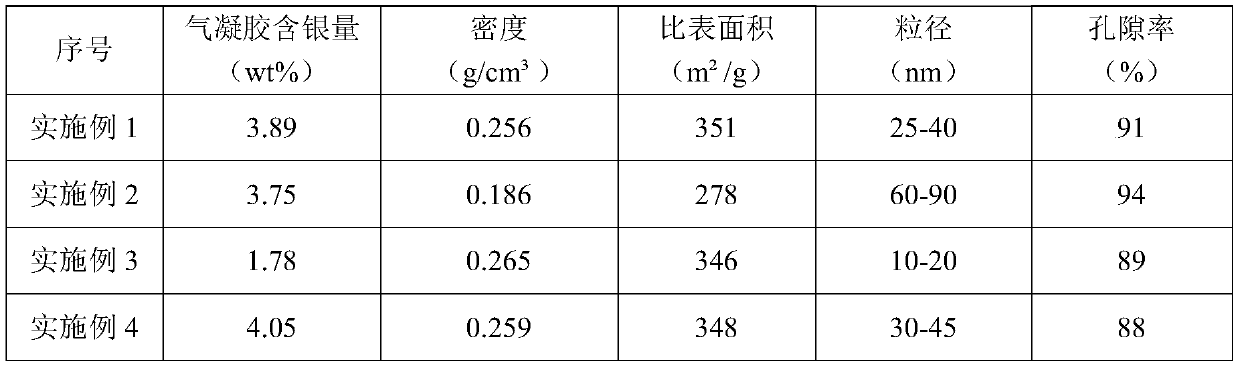

Embodiment 2

[0081] This example differs from Antibacterial Agent Example 1 only in that the mass ratio of liquid-2 type liquid sodium silicate to deionized water is 1:400.

Embodiment 3

[0083] This example differs from Antibacterial Agent Example 1 only in that the content of silver nitrate is 0.05mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com