Molybdenum disulfide quantum dot modified molybdenum carbide/foamed nickel composite material, preparation method and application of the composite material in electrocatalytic oxygen evolution

A technology of molybdenum disulfide and composite materials, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., which can solve complex preparation and few researches on oxygen evolution reaction , loss of catalytic activity and other issues, to achieve the effect of large specific surface area, ensuring electrolyte penetration, and small static contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

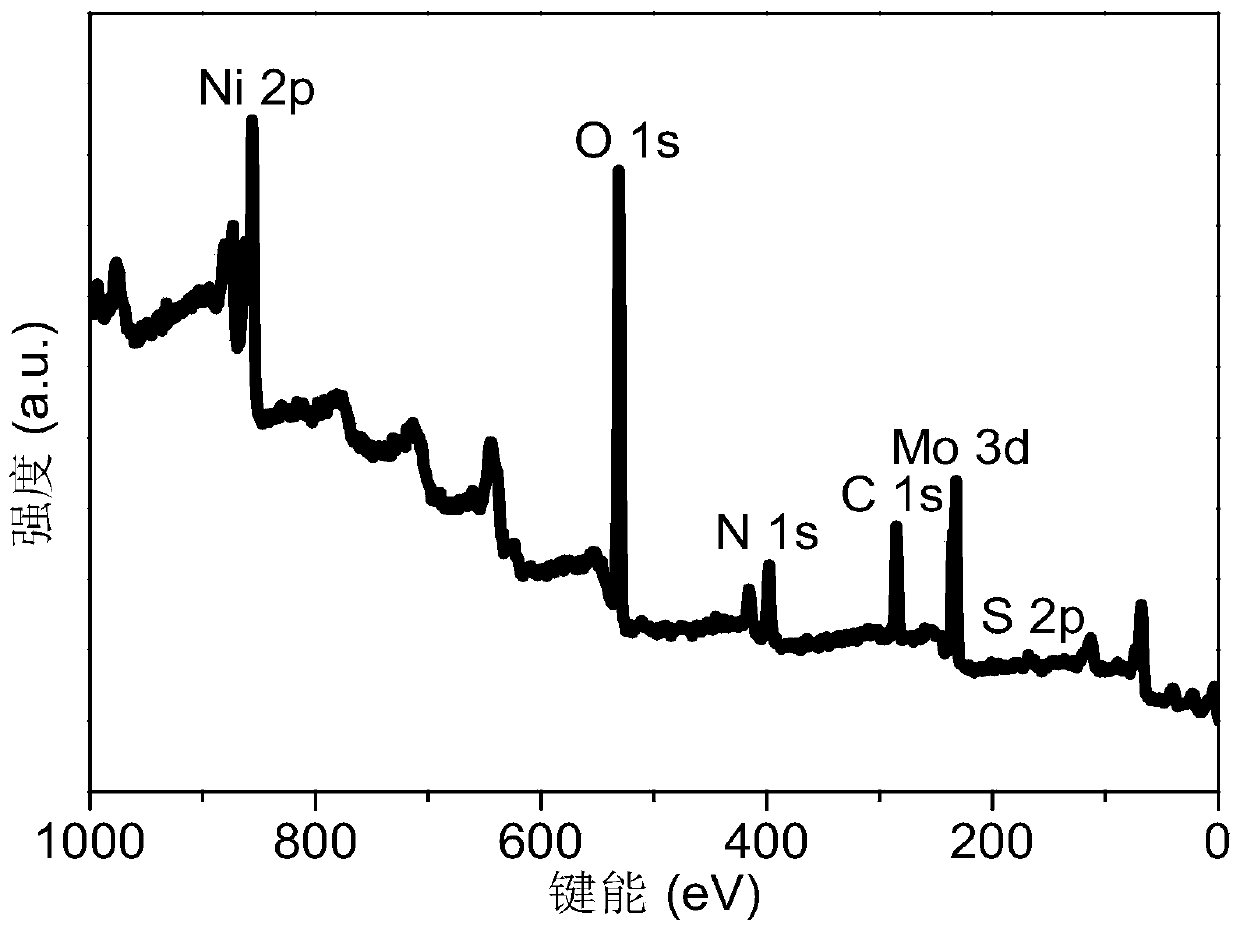

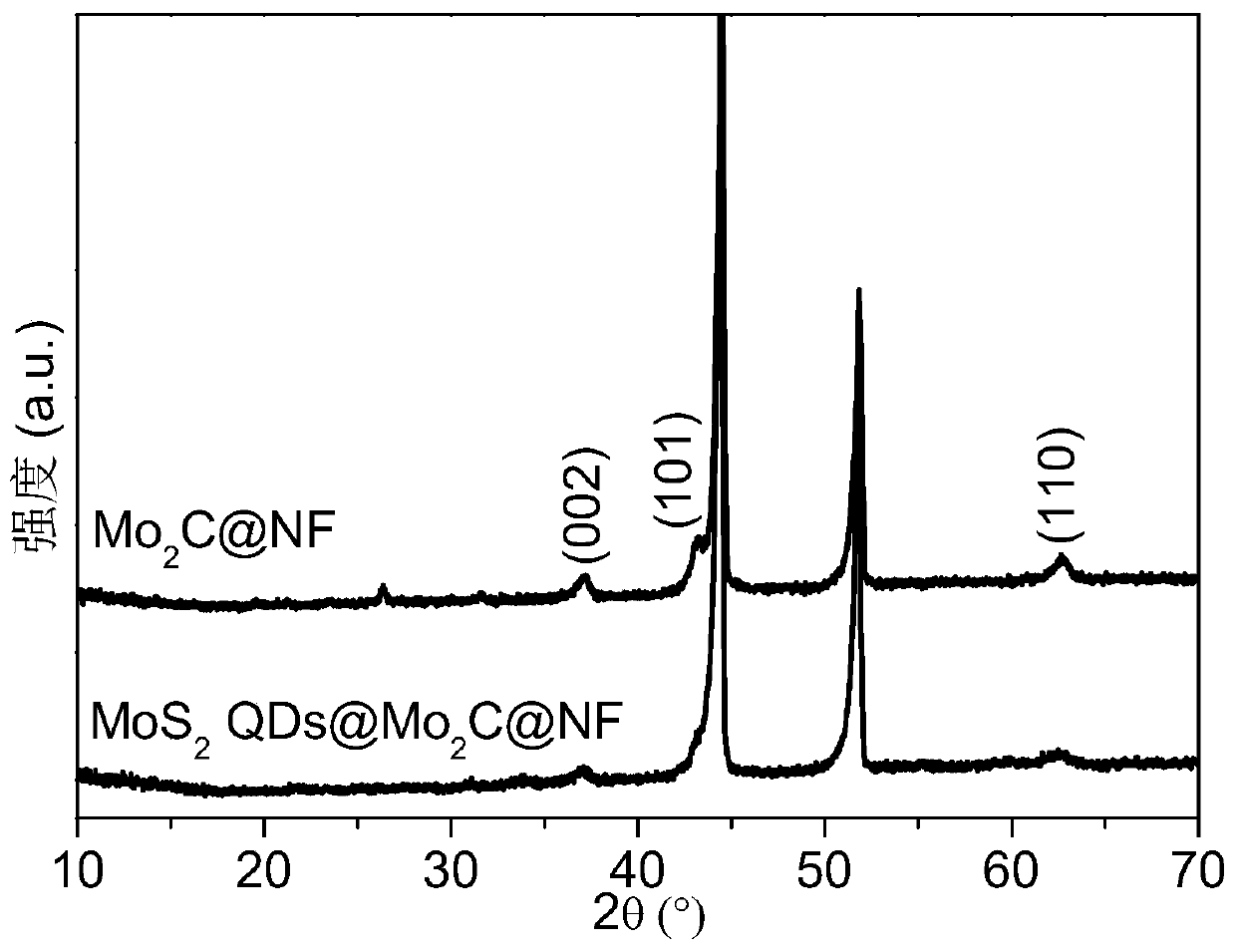

[0050] A molybdenum carbide / nickel foam composite material modified by molybdenum disulfide quantum dots, including molybdenum carbide and nickel foam, molybdenum carbide supported on the nickel foam to form a molybdenum carbide / nickel foam composite material, molybdenum carbide / nickel foam composite material surface growth There are molybdenum disulfide quantum dots.

[0051] In this embodiment, the mass ratio of molybdenum disulfide quantum dots to molybdenum carbide / nickel foam composite is 1.0%; the mass ratio of molybdenum carbide to nickel foam in the molybdenum carbide / nickel foam composite is 1.5%.

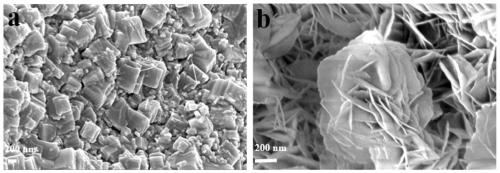

[0052] In this embodiment, the aggregation morphology of the molybdenum disulfide quantum dots grown on the surface of the molybdenum carbide / nickel foam composite material is flake-like; the average particle size of the molybdenum disulfide quantum dots is 4.75 nm. Molybdenum carbide has a block structure and is a cubic particle; the average particle size of molybdenum ca...

Embodiment 2

[0073] A molybdenum carbide / nickel foam composite material modified by molybdenum disulfide quantum dots is basically the same as in Example 1, the only difference being: the mass ratio of molybdenum carbide and nickel foam in the molybdenum carbide / nickel foam composite material used in Example 2 was 1.2%.

[0074] A preparation method of molybdenum carbide / nickel foam composite material modified by molybdenum disulfide quantum dots in the above-mentioned present embodiment is basically the same as that of embodiment 1, the only difference being that in the preparation method of embodiment 2, the molybdenum acid used The ammonium / trisodium citrate aqueous solution contained 0.1 mmol of ammonium molybdate and 0.1 mmol of trisodium citrate.

[0075] The molybdenum carbide / nickel foam composite material and molybdenum carbide / nickel foam composite material modified by molybdenum disulfide quantum dots prepared above were used as working electrodes for electrocatalytic oxygen evo...

Embodiment 3

[0078] A molybdenum carbide / nickel foam composite material modified by molybdenum disulfide quantum dots is basically the same as Example 1, the only difference being: the mass ratio of molybdenum carbide and nickel foam in the molybdenum carbide / nickel foam composite material used in Example 3 was 1.8%.

[0079] A kind of preparation method of molybdenum carbide / nickel foam composite material modified by molybdenum disulfide quantum dots in the above-mentioned present embodiment is basically the same as embodiment 1, the difference is only: in the preparation method of embodiment 3, the molybdenum acid used The ammonium / trisodium citrate aqueous solution contained 0.3 mmol of ammonium molybdate and 0.1 mmol of trisodium citrate.

[0080] The molybdenum carbide / nickel foam composite material and molybdenum carbide / nickel foam composite material modified by molybdenum disulfide quantum dots prepared above were used as working electrodes for electrocatalytic oxygen evolution, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com