Straw raw material pretreatment and sulfonation-hydroxymethylation modification method for straw-based water reducing agent

A technology of hydroxymethylation and pretreatment, which is applied in the field of straw raw material pretreatment and sulfonation-hydroxymethylation modification of straw-based water reducing agent, can solve the problem that the degree and method of straw pulverization are not proposed for fine crushing, and no industrialization is proposed. Test ideas and concepts, insufficient utilization of straw raw materials, etc., to achieve the effects of easy industrial application, low cost, and increased reactive area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

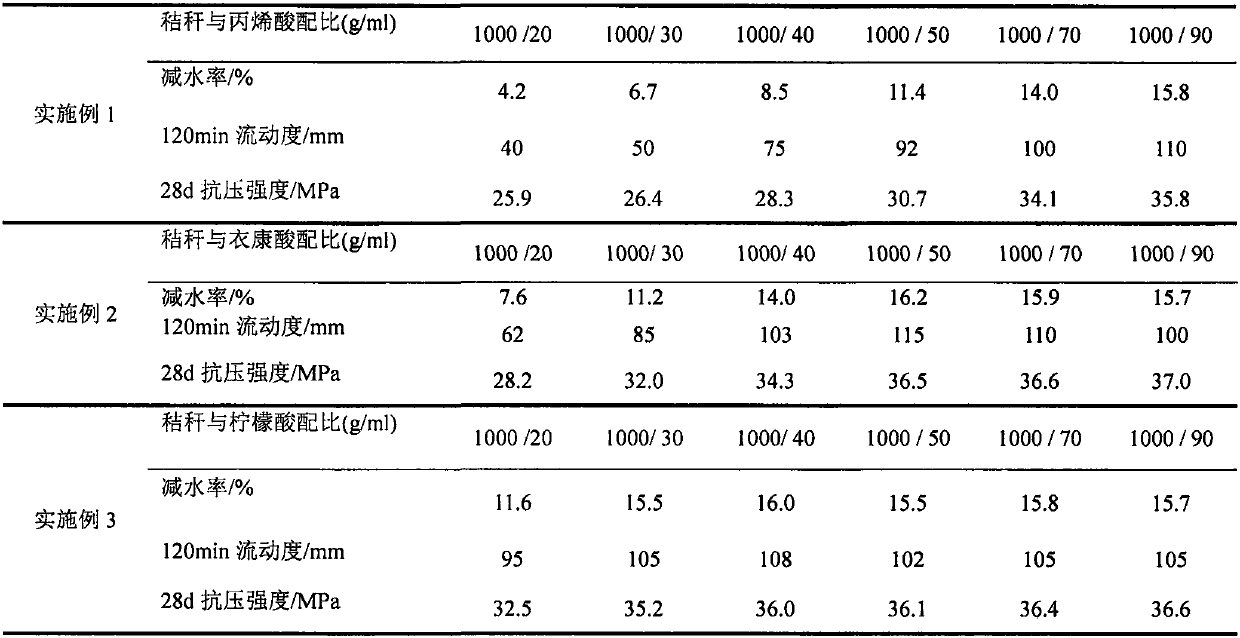

Embodiment 1

[0018] A method for pretreatment of straw raw materials and sulfonation-methylolation modification of straw-based water reducer, the specific steps are as follows:

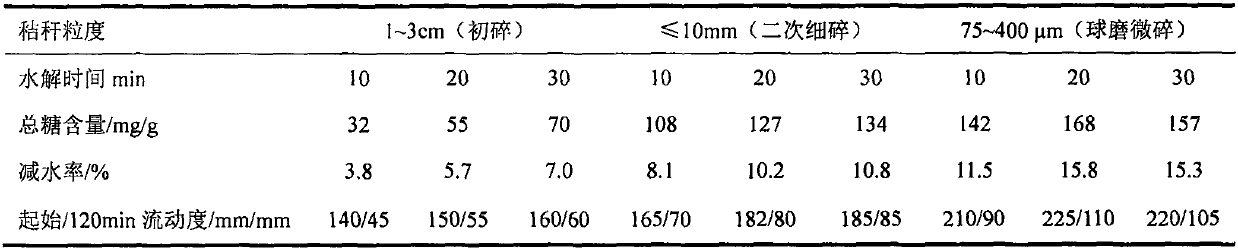

[0019] 1. Primary crushing After a certain amount of raw material straw bales are air-dried naturally, they are crushed into 1-3cm straw segments;

[0020] 2. Cleaning: Clean the silt and other impurities in the straw section after primary crushing;

[0021] 3. Drying The cleaned straw section is dried to keep the moisture content below 10%;

[0022] 4. Secondary crushing: crush the dried straw section into 1-10mm straw section;

[0023] 5. Fine crushing The straw section after secondary crushing is finely crushed by a ball mill, so that the output particle size of the crushed raw material is below 400 μm. The ball mill is a horizontal ball mill, and the particle size of the straw raw material is below 10mm, and the speed is 10-50r / min. 15Kg, 1500 balls, including 1000 copper balls with a diameter of 10mm, 500 c...

Embodiment 2

[0030] A method for pretreatment of straw raw materials and sulfonation-methylolation modification of straw-based water reducer, the specific steps are as follows:

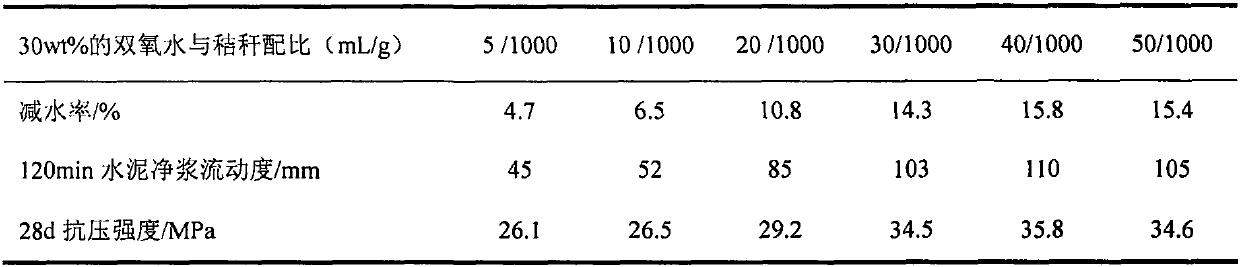

[0031] Steps one, two, three, four, and five are the same as in Example 1, and will not be repeated; the lubricating additive described in step six is stearic acid, and the solid agent ratio of straw and stearic acid is 1000g: 10mL; The main catalytic acid for hydrolysis is itaconic acid, and the ratio of straw to itaconic acid is 1000g: (45-55) mL, more preferably 1000 g: 50 mL; Hydrochloric acid, the proportioning of straw and dilute hydrochloric acid is 1000g: 100mL; All the other are the same as embodiment 1, no longer repeat; The proportioning of solution is 1000g: (30-45) mL, further preferred straw and potassium permanganate solution are 1000g: 40mL; All the other are the same as Example 1, no longer repeat; The sulfonating agent described in step 8 is mass Concentration 50% sodium sulfite, the proportio...

Embodiment 3

[0033] A method for pretreatment of straw raw materials and sulfonation-methylolation modification of straw-based water reducer, the specific steps are as follows:

[0034] Steps 1, 2, 3, 4 and 5 are the same as in Example 1, and will not be repeated; the lubricating additive described in step 6 is a mixture of stearic acid and oleic acid each accounting for 50%, and the solid agent ratio of straw and lubricating additive 1000 g: 8mL; the main catalytic acid for hydrolysis is citric acid, and the ratio of straw and citric acid is 1000g: (30-35) mL, further 1000g: 35mL; the mass concentration of the catalytic promoter for hydrolysis is 30g / L dilute sulfuric acid and dilute hydrochloric acid respectively account for 50% mixed acid, the proportioning of stalks and procatalyst acid is 1000g: 100mL; All the other are the same as embodiment 1, no longer repeat; The oxidizing agent described in the step 7 is mole Potassium permanganate with a concentration of 1.0M and hydrogen peroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com