Polycrystalline B4C-diamond double-layer composite material and preparation method thereof

A composite material and diamond technology, which is applied in the field of polycrystalline B4C-diamond double-layer composite material and its preparation, can solve the problems that limit the large-scale application of polycrystalline diamond, expensive diamond powder, high hardness and high fracture toughness, etc., and achieve crystal The effects of uniform particle size distribution, low density, high temperature stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

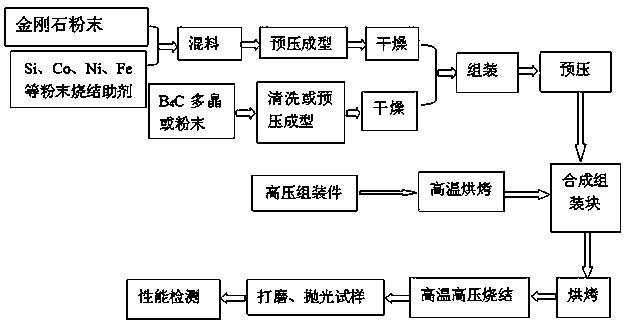

Method used

Image

Examples

Embodiment 1

[0034] a. Raw material processing and testing: take polycrystalline B with a purity of 98% and an average grain size of 10 μm 4 Block C is 30 g; take 27 g of diamond powder with a purity of 98% and an average grain size of 8 μm, add Si powder with a volume fraction of 6% to the diamond powder as a sintering aid, and treat it with 50 ml of absolute ethanol, After pouring out the waste liquid, dry it in an oven at 120 °C; Polycrystalline B 4 Add Si with a volume fraction of 2% as a sintering aid to the C block, treat it with 60 ml of absolute ethanol, pour out the waste liquid, and dry it in an oven at 120 °C. After drying, the polycrystalline B 4 Add 50 ml of deionized water to the C block and diamond powder respectively and pre-press them respectively, and dry the formed samples in a vacuum drying oven;

[0035]b. Assembling the sintering unit: processing the metal inclusions used to wrap the raw materials, grinding and polishing, then degreasing, ultrasonic cleaning, vacuum ...

Embodiment 2

[0040] a. Raw material processing and testing: take polycrystalline B with a purity of 99% and an average grain size of 2 μm 4 Block C is 55 g, and 56 g of diamond powder with a purity of 99% and an average grain size of 25 μm is taken. Co powder with a volume fraction of 2% is added to the diamond powder as a sintering aid, and treated with 100 ml of absolute ethanol. After pouring out the waste liquid, dry it in an oven at 120 °C; Polycrystalline B 4 Block C was treated with 90 ml of absolute ethanol, and after pouring out the waste liquid, it was dried in an oven at 120 °C, and the dried polycrystalline B 4 Add 95 ml of deionized water to the C block and diamond powder respectively and pre-press them respectively, and dry the formed samples in a vacuum drying oven;

[0041] B, this step is identical with the step b in embodiment 1;

[0042] c. High-temperature and high-pressure sintering: Use a six-sided top press for high-temperature and high-pressure sintering. After re...

Embodiment 3

[0046] a. Raw material processing and testing: take polycrystalline B with a purity of 98% and an average grain size of 500 nm 4 C block 85 g, take 66 g of diamond powder with a purity of 99% and an average grain size of 15 μm, treat the diamond powder with 120 ml of absolute ethanol, pour out the waste liquid, and dry it in an oven at 120 °C. Polycrystalline B 4 Block C was treated with 140 ml of absolute ethanol, and after pouring out the waste liquid, it was dried in an oven at 120 °C, and the dried polycrystalline B 4 Add 70 ml of deionized water to the C block and diamond powder respectively and pre-press them respectively, and dry the formed samples in a vacuum drying oven;

[0047] B, this step is identical with the step b in embodiment 1;

[0048] c. High-temperature and high-pressure sintering: Use a six-sided top press for high-temperature and high-pressure sintering. After reaching the set pressure of 10 GPa, heat up and heat at 1500 °C for 5 minutes. After the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com