A kind of composite of graded structure glass fiber and metal lithium and preparation method thereof

A fiberglass, graded structure technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

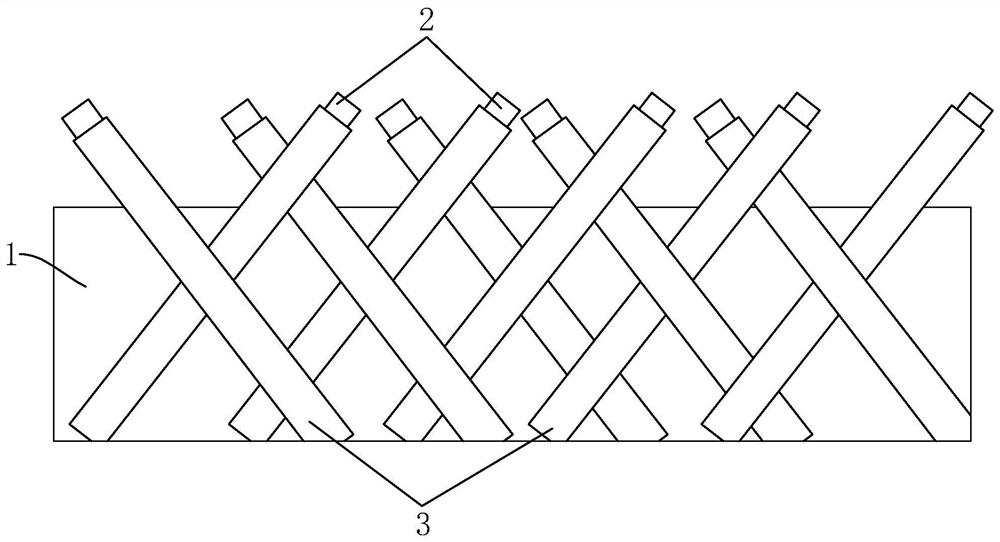

[0046] The thickness of the glass fiber layer 2 inserted in the lithium layer 1 is the same as the thickness of the lithium layer 1, and the thickness of the lithium layer 1 is (positive surface capacity*(1-coulombic efficiency)*5*expected number of cycles+(0 to 10)) μm, so that the lithium in the lithium layer 1 preset at the lower part of the glass fiber layer 2 can be used to replenish the positive electrode, so that the Coulombic efficiency reaches the optimum value; the upper part of the glass fiber layer 2 is exposed above the lithium layer 1 to form a deposition layer, and the thickness of the deposition layer It is (positive electrode surface capacity*5+(0 to 5))μm, so that the glass fiber on the surface of the negative electrode can completely accommodate the newly deposited lithium element.

[0047] Wherein, the preparation method of the compound of hierarchical structure glass fiber and metal lithium comprises the following steps:

[0048] S1, the upper surface of t...

Embodiment 2

[0055] S1, the upper surface of the glass fiber layer 2 is masked by adhesive tape, and the glass fiber is sprayed with an aqueous solution of poly(3,4-ethylenedioxythiophene), combined with the unmasked surface of the glass fiber, and adhered to the surface after drying. A conductive layer 3 is formed on the surface of the glass fiber, and then the adhesive tape is torn off;

[0056] S2, melting lithium metal at 300°C, inserting graded glass fibers into the molten lithium metal, and cooling at room temperature to shape;

[0057] S3, putting the above compound into a sealed bag for isostatic pressing operation, and continuing to press the metal lithium into the graded glass fiber;

[0058] S4, obtaining a composite of hierarchical glass fiber and lithium metal.

[0059] In the embodiment, the total thickness of the glass fiber layer 2 is 100 μm, the thickness of the poly(3,4-ethylenedioxythiophene) covered by the middle and lower surface is 500 nm, and the total thickness of ...

Embodiment 3

[0062] S1, stick the upper surface of the glass fiber layer 2 with adhesive tape for masking, soak the glass fiber with a solution of palladium chloride and tin dichloride, the palladium metal obtained by the reaction will combine with the unmasked surface of the glass fiber, and dry Finally attached to the surface of the glass fiber to form a conductive layer;

[0063] S2, the above composite is connected to the cathode electroplating, and gold can be electroplated on the surface of the glass fiber to form a conductive layer 3;

[0064] S2, melting lithium metal at 300°C, inserting graded glass fibers into the molten lithium metal, and cooling at room temperature to shape;

[0065] S3, putting the above compound into a sealed bag for isostatic pressing operation, and continuing to press the metal lithium into the graded glass fiber;

[0066] S4, obtaining a composite of hierarchical glass fiber and lithium metal.

[0067] In the embodiment, the total thickness of the glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com