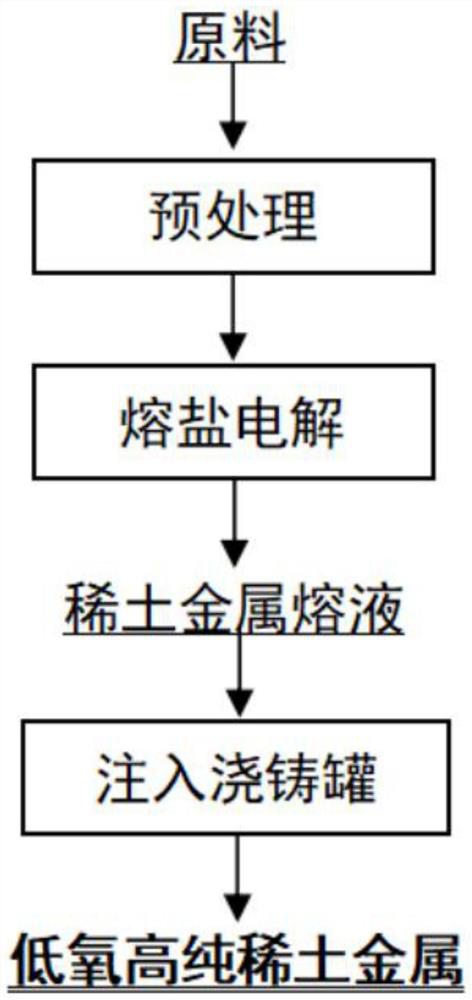

A short process method for preparing low-oxygen high-purity rare earth metals

A rare earth metal, short process technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of inability to achieve high-performance materials, difficult to achieve impurity removal, increased risk of rare earth metals, etc., to simplify operations, reduce production costs and Construction investment, the effect of reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

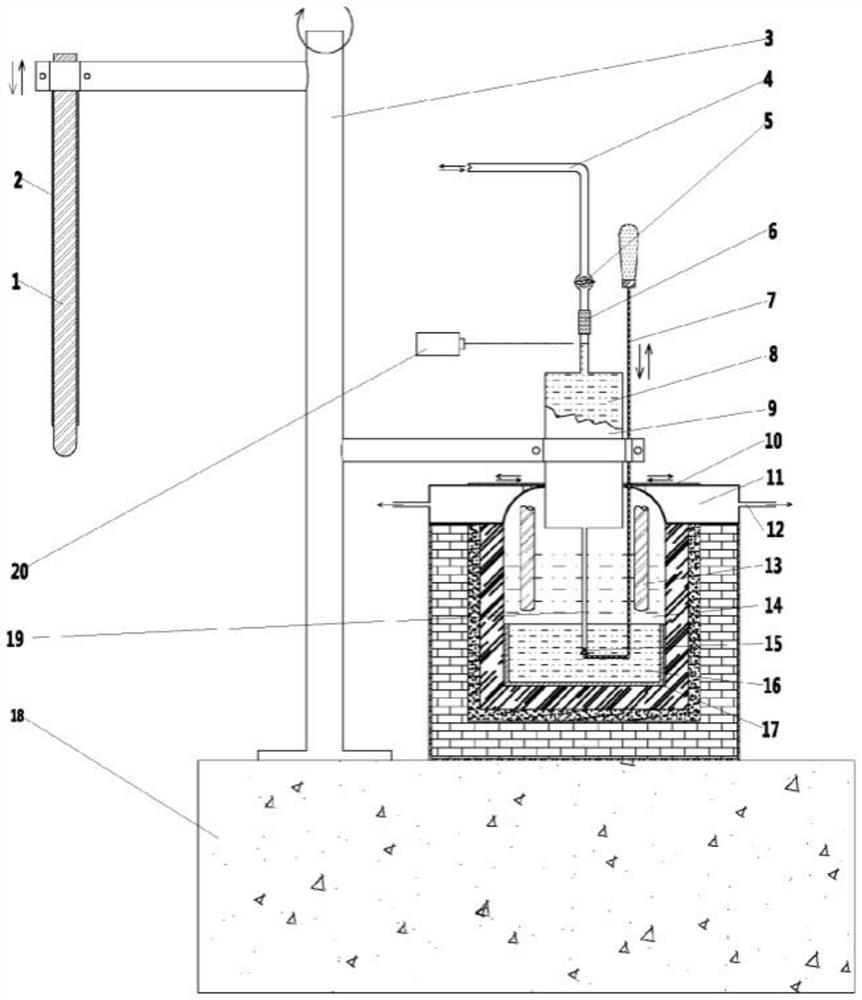

[0032] A short-process method for preparing lanthanum low-oxygen high-purity rare earth metals, comprising the following steps:

[0033]1. To 850 °C burning lanthanum carbonate, newly prepared lanthanum oxide as raw material, purity of 99.93%, add fluoride electrolysis system for molten salt electrolysis, lanthanum fluoride, lithium fluoride and additives the purity is greater than 99.5%, the cathode of the electrolyzer tungsten rod, anode cylindrical graphite. The electrolytic process control cell voltage is 12V and the cathode current density is 6A / cm 2 , anode current density 0.5A / cm 2 , the metal is obtained from the cathode and collected in a molybdenum crucible at the bottom of the electrolyzer.

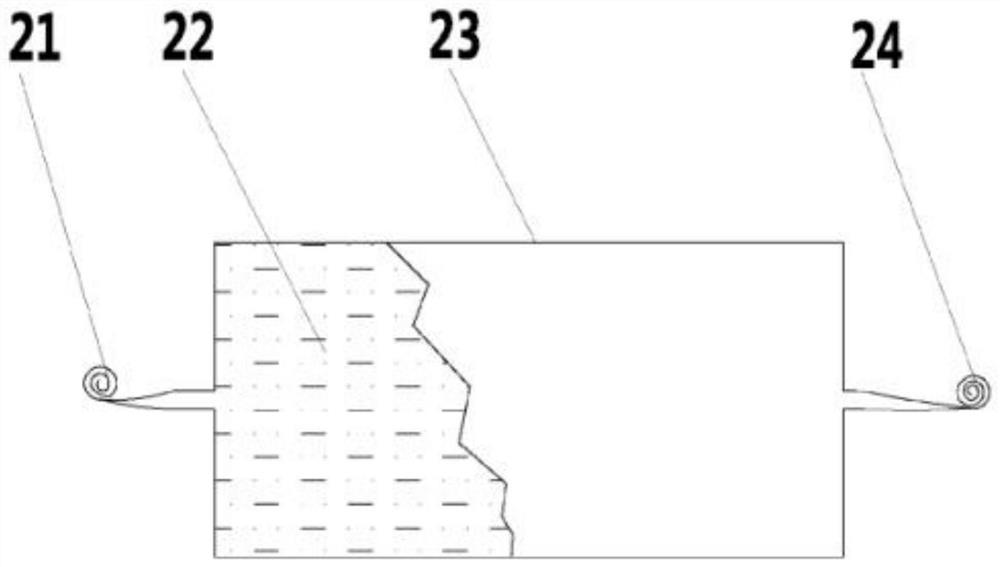

[0034] 2. After 1.5h of electrolysis, take the carbon steel casting tank, pickling, rust removal, hydrogen reduction, baking at 450 °C, immediately connected to the casting device and filled with high-purity argon with a purity of 99.999%, after ventilation for 15min, use a conica...

Embodiment 2

[0039] A short-process method for preparing lanthanum low-oxygen high-purity rare earth metals, comprising the following steps:

[0040] 1. Burn lanthanum oxalate at 800 °C, obtain lanthanum oxide as raw material, purity 99.95%, dehydration at a temperature of 400 °C for 3h, add fluoride electrolysis system for molten salt electrolysis, lanthanum fluoride, lithium fluoride and additives The purity is greater than 99.5%, the cathode tungsten rod of the electrolytic cell, the anode cylindrical graphite. The electrolytic process control cell voltage is 12V and the cathode current density is 7A / cm 2 , anode current density 0.5A / cm 2 , the metal is obtained from the cathode and collected in a molybdenum crucible at the bottom of the electrolyzer.

[0041]2. After 1.5h of electrolysis, take the carbon steel casting tank, pickling, rust removal, hydrogen reduction, drying, attached to the casting device and filled with high-purity argon with a purity of 99.999%, after ventilation for 12...

Embodiment 3

[0046] A short-process method for preparing low-oxygen high-purity rare earth metal praseodymium neodymium comprising the following steps:

[0047] 1. 850 °C burning praseodymium carbonate, the preparation of praseodymium neodymium mixed oxide as raw material, mass ratio of 1:1, metal purity of 99.98%, first at a temperature of 600 °C dehydration 2h pretreatment, add fluoride electrolysis system for molten salt electrolysis, lanthanum fluoride, lithium fluoride, barium fluoride and additives are more than 99.5%, the anion of the electrolytic cell is extremely high purity iron rod, anode cylindrical graphite. The electrolytic process control cell voltage is 12V, and the cathode current density is 8A / cm 2 , anode current density 0.5A / cm 2 , the metal is obtained from the cathode and collected in a molybdenum crucible at the bottom of the electrolyzer.

[0048] 2. After 1.5h of electrolysis, take the carbon steel casting tank, pickling, rust removal, hydrogen reduction, drying, conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com