Method for doping nano black phosphorus or black phosphorus-based mixed material

A hybrid material, black phosphorus-based technology, applied in the field of nanomaterials, can solve the problems of uneven doping of composite materials, easy high-temperature sintering cost, harsh equipment requirements, etc., and achieves improved doping uniformity, good stability, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: The preparation method of this nitrogen-doped perforated black phosphorene / reduced graphene oxide (N-HBP / rGO) composite material is as follows:

[0028] (1) Uniformly disperse 250mg of perforated black phosphorene and 50mg of graphene oxide in 60mL of ethanol to obtain a suspension;

[0029] (2) Place the suspension obtained in step (1) in a quartz glass tube and continuously feed argon and ammonia (ammonia accounts for 50% of the total gas volume), and then irradiate with ultraviolet light under 300r / min magnetic stirring reaction;

[0030] (3) After 72 hours of ultraviolet light irradiation reaction in step (2), the reaction product was subjected to solid-liquid separation, and the obtained solid was freeze-dried to prepare the N-HBP / rGO composite material;

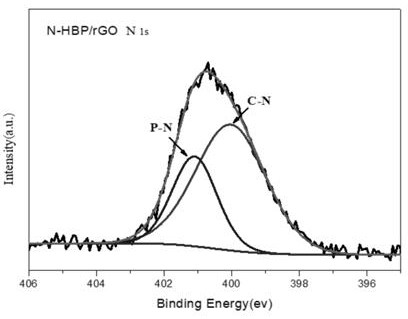

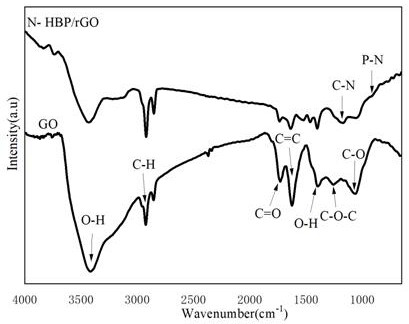

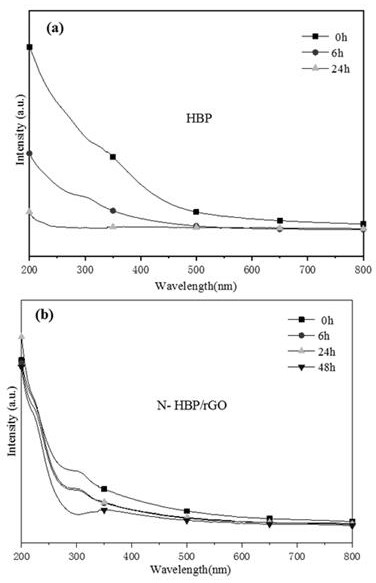

[0031] figure 1 The N1S spectrogram of the nitrogen-doped perforated black phosphorene / reduced graphene oxide composite material obtained in this embodiment, as can be seen from the figure, the P-N a...

Embodiment 2

[0035] Embodiment 2: The preparation method of this sulfur-doped black phosphorus quantum dot is as follows:

[0036] (1) Uniformly disperse 300 mg of black phosphorus quantum dots in 30 mL of N-methylpyrrolidone solvent to obtain a suspension;

[0037] (2) Place the suspension obtained in step (1) in a high borosilicate glass tube and continuously feed helium and hydrogen sulfide (helium accounts for 35% of the total gas volume), and then carry out visible light irradiation reaction under air flow stirring;

[0038](3) After 48 hours of visible light irradiation reaction in step (2), the reaction product is finally subjected to solid-liquid separation, and the obtained solid is vacuum-dried to obtain a sulfur-doped black phosphorus quantum dot material.

Embodiment 3

[0039] Embodiment 3: the preparation method of this carbon and nitrogen double-doped black phosphorus nanobelt / graphene composite material is as follows:

[0040] (1) Uniformly disperse 150mg of black phosphorus nanobelts and 150mg of MXene in 300mL of dimethyl sulfoxide solvent to obtain a suspension;

[0041] (2) Place the suspension obtained in step (1) in a quartz glass tube, and continuously feed nitrogen, ethylene and ammonia (ethylene and ammonia account for 60% of the total volume of the gas, and the volume ratio of ethylene and ammonia is 1: 1), and then carry out ultraviolet light irradiation reaction under jet stirring;

[0042] (3) After 2 hours of reaction under ultraviolet light irradiation in step (2), the solid-liquid separation of the reaction product was carried out, and the obtained solid was dried naturally to obtain a carbon and nitrogen double-doped black phosphorus nanoribbon / MXene composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com