Highly dispersed coal/heavy oil hydrogenation co-refining catalyst prepared by carrier coal modification

A heavy oil hydrogenation, high dispersion technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, preparation of liquid hydrocarbon mixtures, etc. The problems of aggregation and accumulation and the small specific surface area of the carrier coal can achieve the effect of easy and cheap raw material availability, environmental friendliness, and increased loading capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

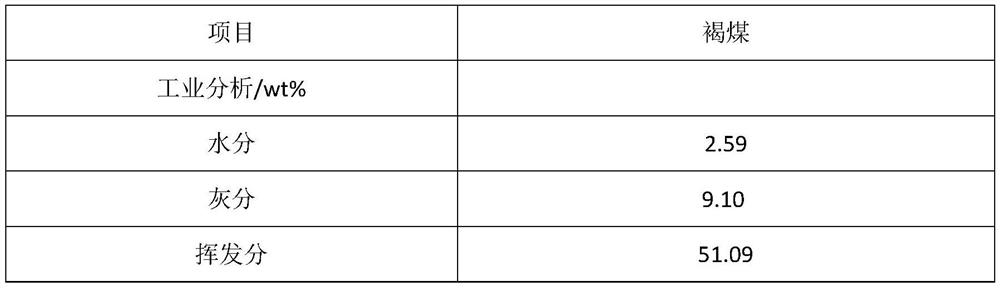

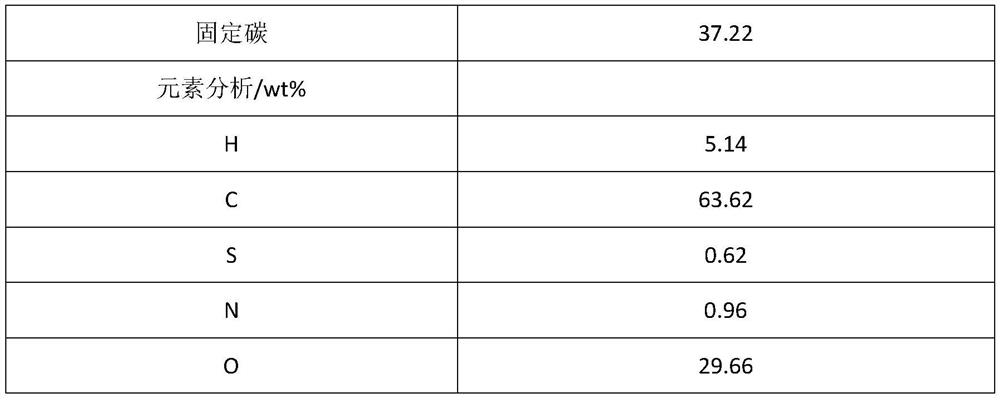

[0035] This example provides a carrier coal modification to prepare a highly dispersed briquette / heavy oil hydrogenation co-smelting catalyst, which is a highly dispersed catalyst with pore-forming pretreated coal powder as the carrier and metal iron and nickel as the active component. The preparation method of described catalyst comprises the steps:

[0036] (1) Put the carrier coal in a blast drying oven at 110°C for 3 hours of drying treatment;

[0037] (2) Get 2.3705g of ferrous sulfate heptahydrate and 2.3593g of nickel nitrate hexahydrate and add deionized water to prepare a uniform solution, mix and stir 10g of coal powder and mixed salt solution, and disperse evenly by ultrasonic vibration;

[0038] (3) Under magnetic stirring, add 2 mol / L ammonia solution dropwise to carry out precipitation reaction, control the temperature at 30°C, pH value is 7, react for 2 hours, and obtain the precipitate;

[0039] (4) Add alkaline solution drop by drop under the situation of vio...

Embodiment 2

[0043] This example provides a carrier coal modification to prepare a highly dispersed briquette / heavy oil hydrogenation co-smelting catalyst, which is a highly dispersed catalyst with pore-forming pretreated coal powder as the carrier and metal iron and nickel as the active component. The preparation method of described catalyst comprises the steps:

[0044] (1) Place the raw coal powder in a tube furnace under the protection of nitrogen, the heating rate is 10°C / min, the carbonization temperature is 500°C, the carbonization is 80min, and the carbonization material is obtained by cooling;

[0045] (2) Fully mix and stir the carbonized material and the activator, the activator is KOH, the mass ratio of the carbonized material to the activator is 2.5:1, maintain at 800°C for 60 minutes; after cooling to room temperature, use 0.1mol / L hydrochloric acid Wash with deionized water until neutral, and the product is dried to obtain a porous material with a high specific surface area;...

Embodiment 3

[0052] This example provides a carrier coal modification to prepare a highly dispersed briquette / heavy oil hydrogenation co-smelting catalyst, which is a highly dispersed catalyst with pore-forming pretreated coal powder as the carrier and metal iron and nickel as the active component. The preparation method of described catalyst comprises the steps:

[0053] (1) Place the raw coal powder in a tube furnace under the protection of nitrogen, the heating rate is 5°C / min, the carbonization temperature is 550°C, carbonization is 60min, and the carbonization material is obtained by cooling;

[0054] (2) Fully mix and stir the carbonized material and the activator, the activator is NaOH, the mass ratio of the carbonized material to the activator is 2:1, maintain at 850°C for 60 minutes; after cooling to room temperature, use 0.1mol / L hydrochloric acid Wash with deionized water until neutral, and the product is dried to obtain a porous material with a high specific surface area;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com