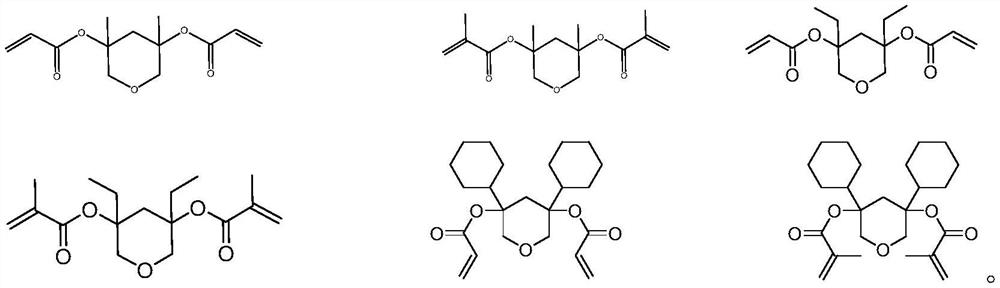

Degradable photoresist resin monomer synthesized from pyran-3, 5-diketone and synthesis method thereof

A technology of resin monomer and synthesis method, applied in the field of resin monomer and its synthesis, can solve the problems of insufficient resolution, weak etching resistance, etc., and achieve the advantages of good solubility, good etching resistance and improved edge roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

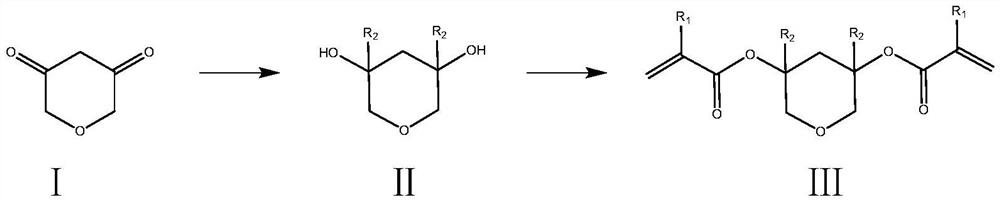

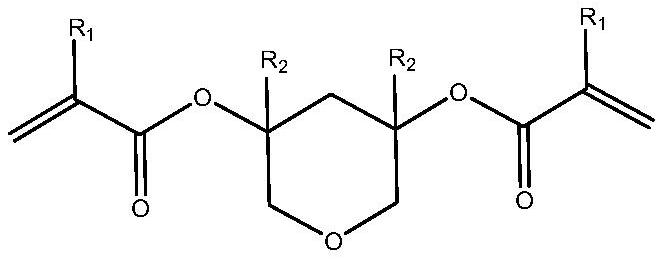

Method used

Image

Examples

Embodiment 1

[0021]

[0022] The first step: a. Preparation of methyl Grignard reagent: adding magnesium chips (4.3g, 177mmol) to anhydrous ether (15mL), then adding an iodine tablet, and dissolving methyl bromide (17g, 179mmol) Prepare a solution in diethyl ether (25mL). Under nitrogen protection, first add methyl bromide diethyl ether solution (6mL) to the above reaction solution. After a few minutes, the reaction solution boils slightly and the color of iodine disappears. Continue to drop Add the remaining ether solution of methyl bromide, add ether (20mL), raise the temperature and keep boiling slightly, and reflux for half an hour; b. Synthesis of intermediate 1-2: Cool the prepared methyl Grignard reagent with ice water, stir Add a solution of 2H-pyran-3,5(4H,6H)-dione 1-1 (10g, 87.6mmol) in diethyl ether (20mL) dropwise, control the rate of addition, and keep the reaction solution slightly boiling. After the addition, Stirring was continued for half an hour at 25 degrees Celsius,...

Embodiment 2

[0025]

[0026] The first step: the operation steps and raw material dosage are the same as the first step reaction of Example 1, and the reaction obtains compound 2-2 (10.8g, 73.9mmol, 84.3%);

[0027] The second step: the operation steps are the same as the second step reaction of Example 1, intermediate 1-2 (10.6g, 72.5mmol) is replaced by intermediate 2-2 (10.8g, 73.9mmol), acryloyl chloride (13.5g, 149 mmol) was replaced by methacryloyl chloride (15.5 g, 148 mmol) to obtain compound 2-3 (16.7 g, 59.2 mmol, 80.1%).

Embodiment 3

[0029]

[0030] The first step, the operating steps are the same as the first step of Example 1, wherein methyl bromide (17g, 179mmol) is changed to ethyl bromide (19.2g, 176mmol), to obtain compound 3-2 (12.3g, 70.6mmol, 80.5 %);

[0031] The second step: the operation steps are the same as the second step of Example 1, the intermediate 1-2 (10.6g, 72.5mmol) is replaced by 3-2 (12.3g, 70.6mmol), and triethylamine (30g, 296mmol) is replaced Triethylamine (29g, 287mmol), acryloyl chloride (13.5g, 149mmol) was replaced by acryloyl chloride (13g, 144mmol) to obtain compound 3-3 (16.5g, 58.4mmol, 82.8%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com