Perovskite photovoltaic cell based on P-type Au@Cu2-xS interface passivation layer material

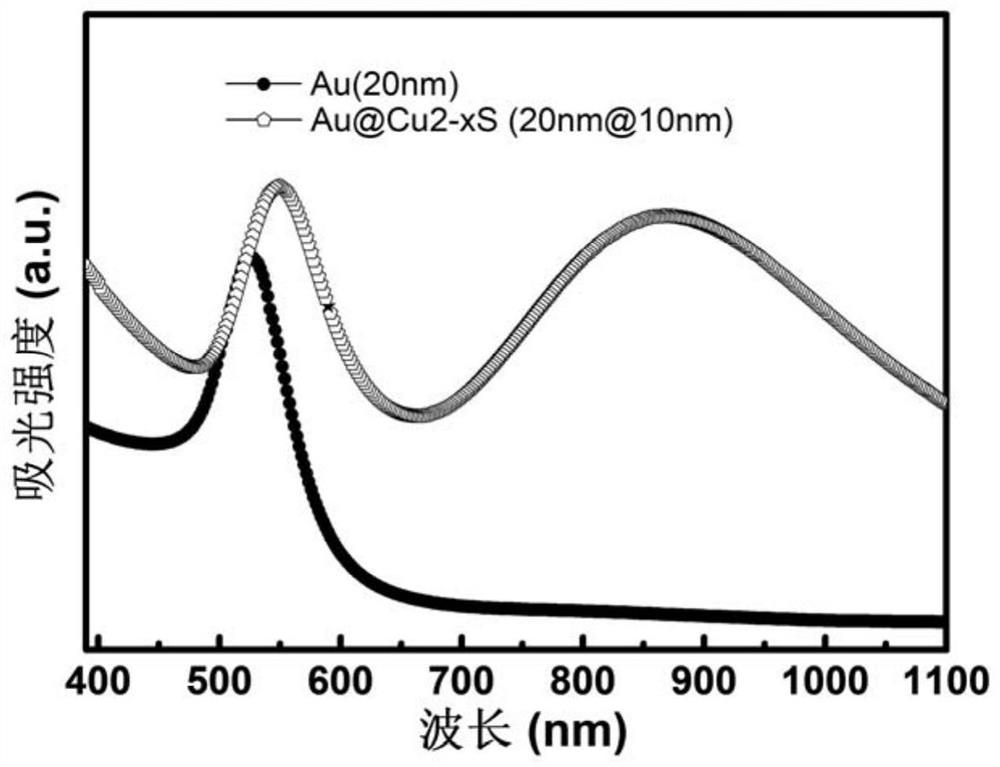

A photovoltaic cell, passivation layer technology, applied in nanotechnology for materials and surface science, photovoltaic power generation, nanotechnology for information processing, etc., can solve difficult chlorobenzene dispersion, inability to perovskite/holes problems such as passivation of the interface between the transport layers, to achieve the effects of inhibiting diffusion, promoting charge separation and extraction, and improving fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

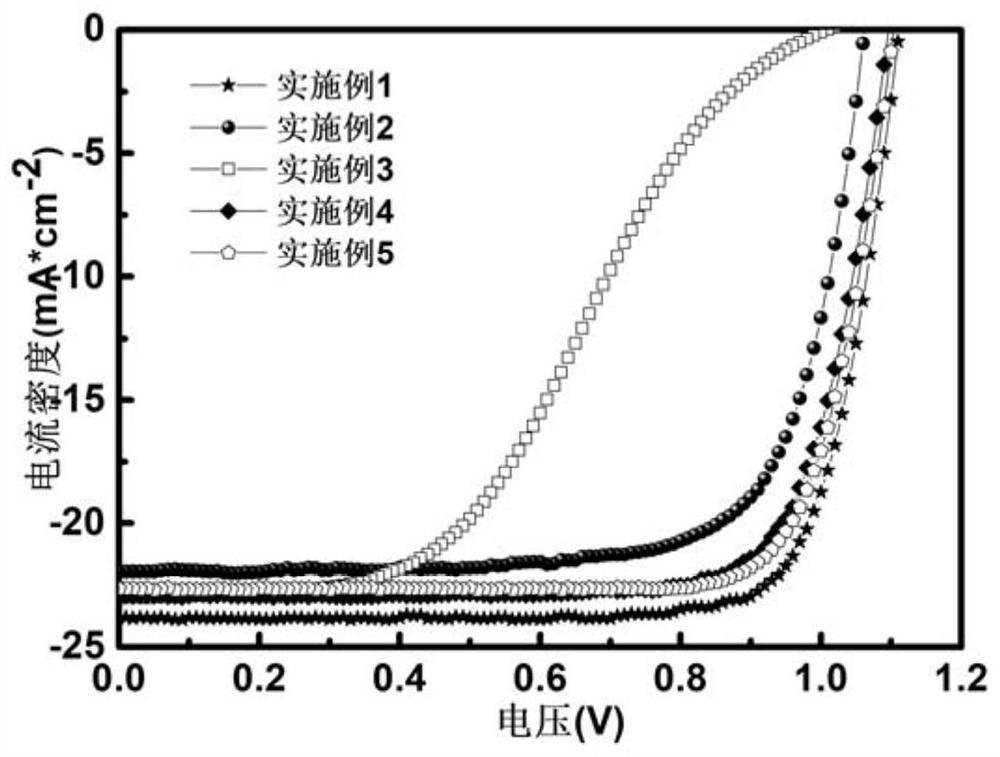

Embodiment 1

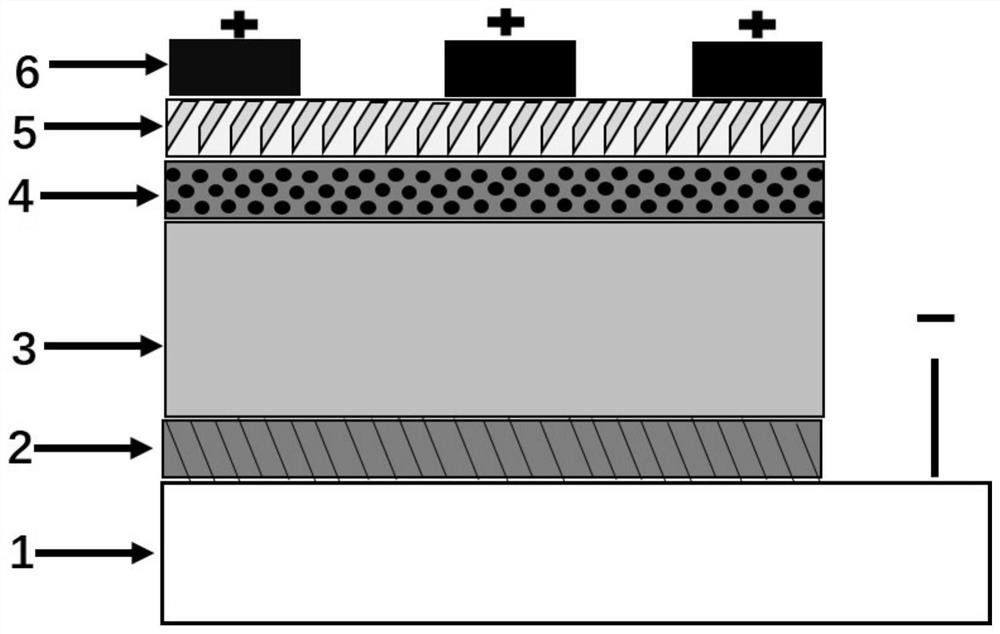

[0047] A planar structure perovskite photovoltaic cell, the structure schematic diagram is as follows figure 2 As shown, its structure includes a transparent conductive substrate 1, an electron transport layer 2, a perovskite photosensitive active layer 3, an interface passivation layer 4, a hole transport layer 5 and a metal electrode 6 from bottom to top, and its preparation method includes the following steps :

[0048] (1) Treatment of transparent conductive substrate: cleaning FTO (fluorine-doped SnO 2 ) conductive glass sheet, first soak the conductive glass sheet in a solution containing detergent for 30 minutes, then rinse it with clean water after repeated scrubbing; then polish it with polishing powder; then put it into deionized water, acetone Ultrasonic for 20 minutes respectively in the container of alcohol and alcohol; finally put in deionized water to rinse twice, blow dry with nitrogen gun and dry in an oven at 80°C;

[0049] (2)SnO 2 QD thin film preparat...

Embodiment 2

[0067] A planar structure perovskite photovoltaic cell comprises a transparent conductive substrate, an electron transport layer, a perovskite photosensitive active layer, an interface passivation layer, a hole transport layer and a metal electrode, and its preparation method comprises the following steps:

[0068] (1) cleaning ITO conductive glass sheet: with embodiment 1;

[0069] (2)SnO 2 Film preparation: SnCl 2 2H 2 O was dissolved in ethanol, coated on the ITO conductive substrate by spin coating method, and annealed at 180 °C for 1 hour in air to prepare SnO 2 film, and put it into a UV-ozone cleaner, and treat it with UV-ozone for 15 minutes in an atmospheric atmosphere and at room temperature, and the treated SnO 2 / ITO substrate is quickly transferred into the glove box;

[0070] (3) Preparation of perovskite photosensitive active layer: same as Example 1;

[0071] (4) Prepare an interface passivation layer on the perovskite photosensitive film:

[0072] a. Au@...

Embodiment 3

[0084] A planar structure perovskite photovoltaic cell comprises a transparent conductive substrate, an electron transport layer, a perovskite photosensitive active layer, an interface passivation layer, a hole transport layer and a metal electrode, and its preparation method comprises the following steps:

[0085] (1) cleaning FTO conductive glass sheet: with embodiment 1;

[0086] (2)SnO 2 Preparation of QD film: same as Example 1;

[0087] (3) Preparation of perovskite photosensitive active layer: same as Example 1;

[0088] (4) Prepare an interface passivation layer on the perovskite photosensitive film:

[0089] a. Au@Cu with core-shell structure 2-x Preparation of S nanoparticles:

[0090] ① Prepare 0.10mol / L CTAB solution and 5mmol / L HAuCl respectively 4 Solution, 15mmol / L NaBH 4 Solution, AA solution of 15mmol / L, NaOH solution of 1.0mmol / L, hexamethylenetetramine solution of 0.1mol / L, thioacetamide solution of 0.1mol / L, copper nitrate solution of 0.1mol / L, spar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com