Bifunctional catalyst for preparing 3-pentanone through methanol-butanone alkylation and preparation method and application thereof

A bifunctional catalyst, butanone alkyl technology, applied in the direction of carbon-based compound preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the application limitations of large-scale industrial production, raw materials Low utilization rate of methanol, easy coking on the surface of the catalyst, etc., to achieve the effects of reducing pyrolysis and carbon deposition, high utilization efficiency, and moderate catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

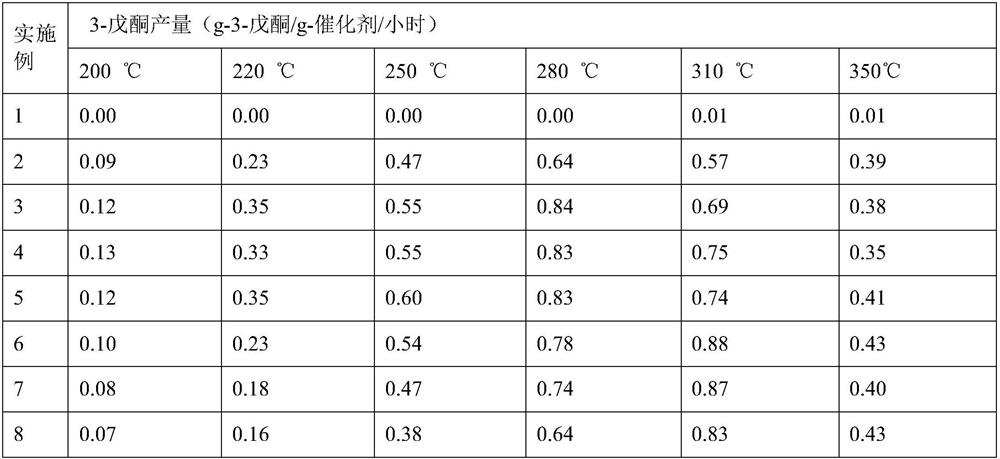

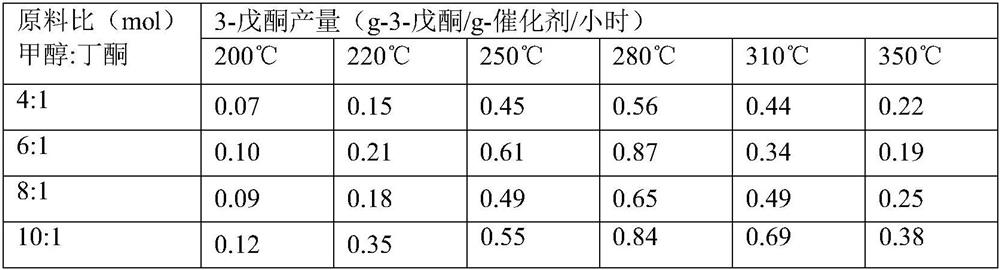

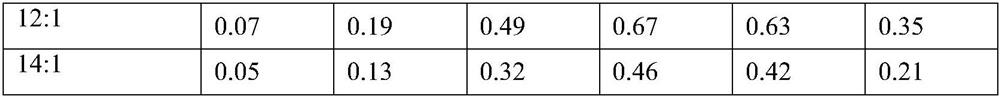

Examples

preparation example Construction

[0039] In a second aspect, a method for preparing the above-mentioned bifunctional catalyst comprises the following steps:

[0040] 1) Ni(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 Dissolve O together in deionized water and stir to form a uniform and transparent mixed solution.

[0041] 2) with step 1) gained mixed solution and NaOH / Na 2 CO 3 The mixed aqueous solution is titrated in parallel, and the pH value of the titrated mixed solution is controlled at 8.0-9.5; after the titration is completed, the stirring is continued at room temperature for 2-4h.

[0042] 3) Suction filtration and washing with deionized water After the solid obtained in step 2) is precipitated to neutrality, the product is dried at 90-110°C for 10-15h; then the dried powder is calcined at 300-400°C for 3-5h in an air atmosphere.

[0043] 4) The solid catalyst obtained after roasting is pressed into tablets and sieved, and the part of 40-80 mesh is take...

Embodiment 1

[0048] Embodiment 1 (catalyst preparation example, without zinc oxide)

[0049] First weigh 0.58g Ni(NO 3 ) 2 ·6H 2 O, 30.26g Mg(NO 3 ) 2 ·6H 2 O, 7.5g Al(NO 3 ) 3 9H 2 O, and dissolved it in 100 mL of deionized water, called solution A. At the same time, weigh 11.2g of NaOH and 5.3g of NaOH 2 CO 3 solid, and dissolved the solid together in 100 mL of deionized water, called solution B. After the solid is completely dissolved, pour the two into two separating funnels respectively, then take a 1000mL beaker, add 100mL deionized water in advance, and put in a magnet for stirring. After the instrument is assembled, open the funnels containing solution A and solution B respectively, let the liquid drop drop by drop, and monitor the pH value of the mixed solution in real time with a precision pH meter. During the titration, keep the pH of the mixture in the range of 8.5-9.0. After the titration, the mixture was continuously stirred at room temperature for 3 h. The soli...

Embodiment 2

[0050] Embodiment 2 (catalyst preparation example, without zinc oxide)

[0051] Weigh 2.91gNi(NO 3 ) 2 ·6H 2 O, 28.21gMg(NO 3 ) 2 ·6H 2 O, 7.5g Al(NO 3 ) 3 9H 2 O solid, and dissolved it in 100 mL of deionized water, called solution A. Solution B, precipitation process, washing, drying, roasting and sieving process are completely consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com