Inert gas purification catalyst, raw material composition and preparation method

A raw material composition and inert gas technology, applied in the direction of inert gas compounds, physical/chemical process catalysts, nitrogen compounds, etc., can solve the problems of high cost, non-renewable, unfavorable industrial use, etc., achieve low production cost, increase adsorption, Remove the effect of deep depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

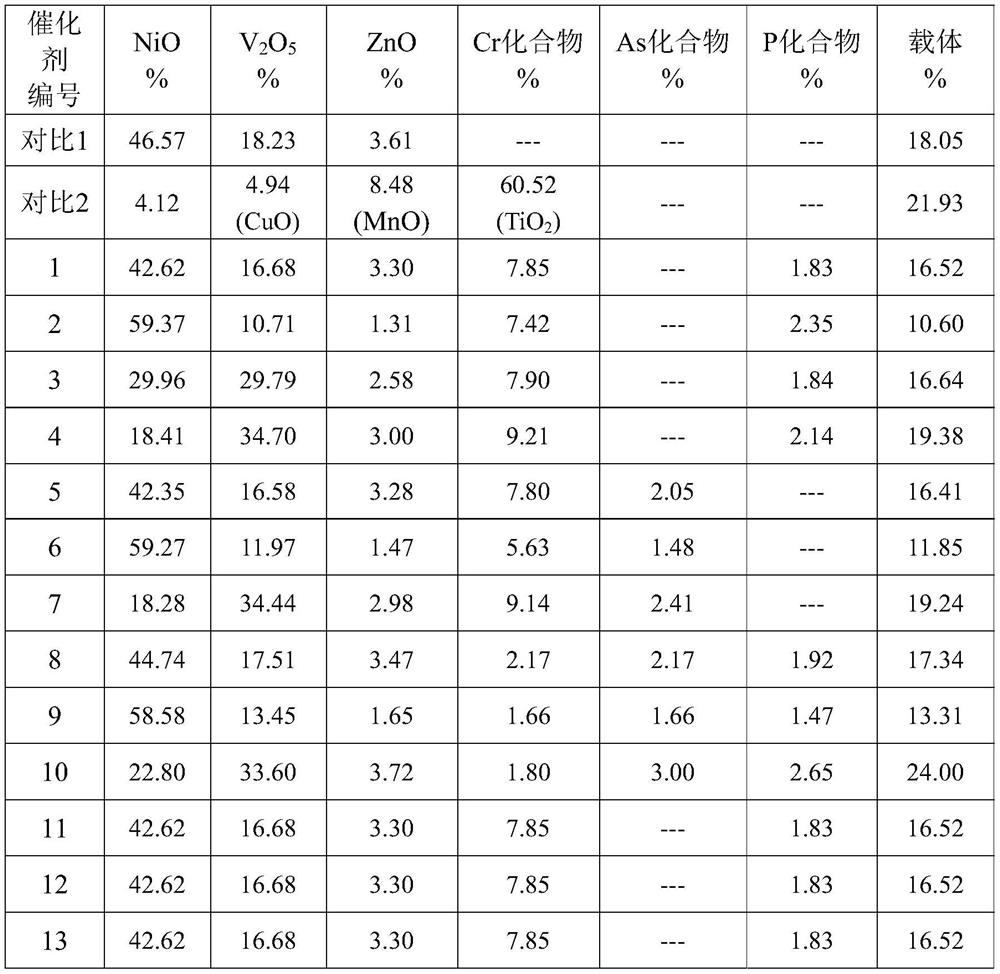

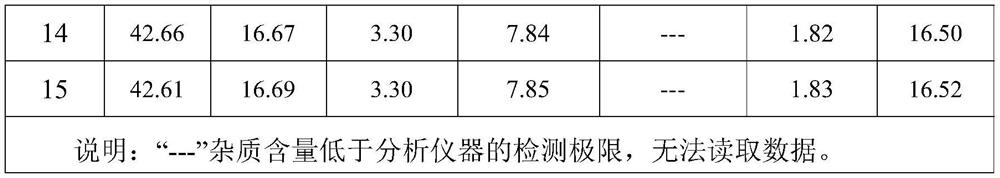

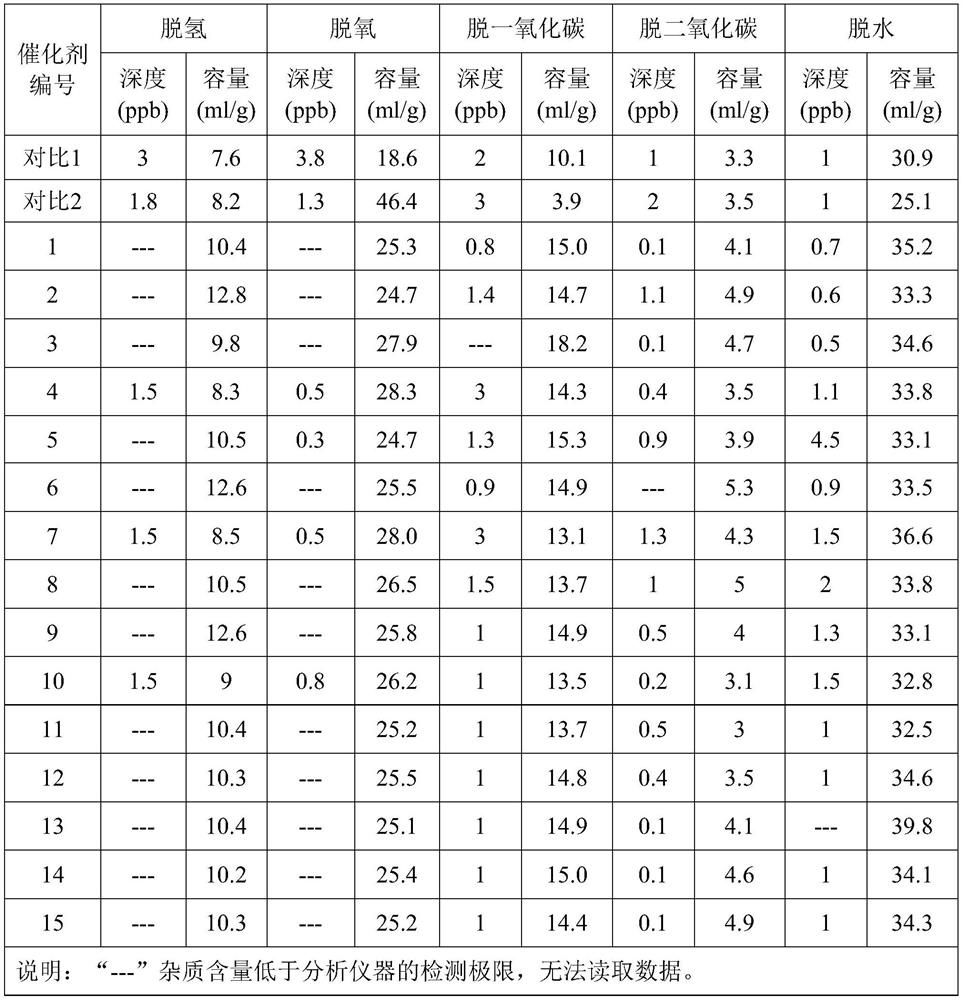

Embodiment 1

[0036] (1) After grinding 9.5g of sodium chromate and 2.5g of ammonium phosphate in a ball mill, add them to 300ml of ethanol solution and process them with ultrasonic waves for 2 hours. (2) Weigh 86 g of basic nickel carbonate, 13 g of ammonium metavanadate and 8.5 g of basic zinc carbonate, grind them in a ball mill, mix them, and add the mixture to the ethanol mixture containing sodium chromate and ammonium phosphate. Stir at room temperature (25° C.) for 6 hours, collect the solids by filtration, and dry the catalyst active component and auxiliary agent mixture. (3) Weigh 20 g of beta molecular sieve and fully mix with the dried catalyst active component and auxiliary agent mixture, and finally use aluminum sol with an aluminum content of 5% as a binder for molding. (4) After forming, the catalyst was dried naturally in an oven at 110° C. overnight, then transferred to a muffle furnace with nitrogen protection gas, and roasted at 350° C. for 6 hours to obtain catalyst No. ...

Embodiment 2

[0038] (1) After grinding 14g of sodium chromate and 5g of ammonium phosphate in a ball mill, add them to 300ml of ethanol solution, and process them with ultrasonic waves for 2 hours. (2) Weigh 187g of basic nickel carbonate, 13g of ammonium metavanadate and 5.2g of basic zinc carbonate, grind them in a ball mill, mix them, and add the mixture to the ethanol mixture containing sodium chromate and ammonium phosphate. Stir at room temperature (25° C.) for 6 hours, collect the solids by filtration, and dry the catalyst active component and auxiliary agent mixture. (3) Weigh 20 g of beta molecular sieve and fully mix with the dried catalyst active component and auxiliary agent mixture, and finally use aluminum sol with an aluminum content of 5% as a binder for extrusion molding. (4) The molded catalyst was dried naturally in an oven at 110°C overnight, then transferred to a muffle furnace with nitrogen protection gas, and roasted at 350°C for 6 hours to obtain catalyst No. 2.

Embodiment 3

[0040] (1) After grinding 9.5g of sodium chromate and 2.5g of ammonium phosphate in a ball mill, add them to 300ml of ethanol solution and process them with ultrasonic waves for 2 hours. (2) Weigh 60 g of basic nickel carbonate, 23 g of ammonium metavanadate and 6.5 g of basic zinc carbonate, grind them in a ball mill, mix them, and add the mixture to the ethanol mixture containing sodium chromate and ammonium phosphate. Stir at room temperature (25° C.) for 6 hours, collect the solids by filtration, and dry the catalyst active component and auxiliary agent mixture. (3) Weigh 20 g of beta molecular sieve and fully mix with the dried catalyst active component and auxiliary agent mixture, and finally use aluminum sol with an aluminum content of 5% as a binder for extrusion molding. (4) The molded catalyst was dried naturally in an oven at 110° C. overnight, then transferred to a muffle furnace with nitrogen protective gas, and calcined at 350° C. for 6 hours to obtain catalyst N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com