Preparation method of micron cobalt disulfide composite material

A composite material, cobalt disulfide technology, applied in the preparation/purification of cobalt sulfide and carbon, chemical instruments and methods, etc., can solve the problems of low tap density, high content of various types of impurities, single function of carbon skeleton, etc. The effect of preventing structural collapse and severe deformation, mitigating stress shocks, and enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of ZIF-67 and carbon nanotube composite precursor: Dissolve 1.9g cobalt chloride, 0.6g 2-nitroimidazole, and 2.0g carbon nanotube slurry in methanol, mix well and perform solvothermal reaction, The temperature is 40°C, and the reaction time is 6h. The carbon nanotube slurry is obtained by dissolving multi-walled carbon nanotubes in N-methylpyrrolidone at a mass percentage of 7% and subjecting them to vacuum grinding at 200 r / min. The molar ratio of cobalt chloride to 2-methylimidazole is 1:0.5; the mass ratio of the total mass of cobalt chloride and 2-methylimidazole to the carbon nanotube slurry is 1:0.8.

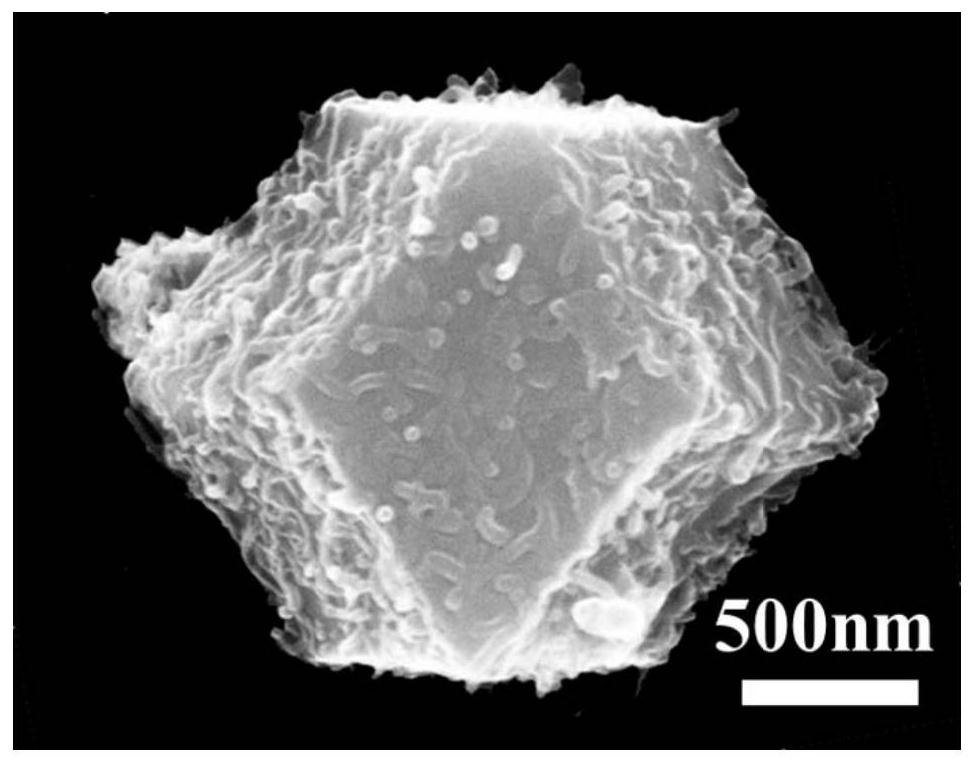

[0024] (2) Carbonize the ZIF-67 and carbon nanotube composite precursor prepared in step (1): Slowly heat the ZIF-67 and carbon nanotube composite precursor material prepared in step (1) in a vacuum environment to obtain Porous dodecahedral composite intermediate product; the heat treatment includes a heating rate of 1°C / min, a heat treatment temper...

Embodiment 2

[0028] (1) Preparation of ZIF-67 and carbon nanotube composite precursor: Dissolve 2.9g cobalt nitrate, 1.2g 2-nitroimidazole, and 12.3g carbon nanotube slurry in diethylene glycol, mix well and perform solvothermal Reaction, the temperature is 50°C, and the reaction time is 9h. The carbon nanotube slurry is obtained by dissolving multi-walled carbon nanotubes in N-methylpyrrolidone at a mass percentage of 2% and subjecting them to vacuum grinding at 400 r / min. The molar ratio of cobalt nitrate and 2-nitroimidazole is 1:1; the mass ratio of the total mass of cobalt nitrate and 2-nitroimidazole to the carbon nanotube slurry is 1:3.

[0029] (2) Carbonize the ZIF-67 and carbon nanotube composite precursor prepared in step (1): Slowly heat the ZIF-67 and carbon nanotube composite precursor material prepared in step (1) in a vacuum environment to obtain Porous dodecahedral composite intermediate product; the heat treatment includes a heating rate of 2°C / min, a heat treatment temp...

Embodiment 3

[0033] (1) Preparation of ZIF-67 and carbon nanotube composite precursor: Dissolve 2.8g cobalt sulfate, 3g 2-pyridinecarboxylic acid, and 34g carbon nanotube slurry in ethylene glycol, mix them evenly, and perform solvothermal reaction at a temperature of 60°C, reaction time 12h. The carbon nanotube slurry is obtained by dissolving multi-walled carbon nanotubes in N-methylpyrrolidone at a mass percentage of 5%, and subjecting them to vacuum grinding at 800 r / min. The molar ratio of cobalt nitrate and 2-nitroimidazole is 1:2.5; the mass ratio of the total mass of cobalt nitrate and 2-nitroimidazole to the carbon nanotube slurry is 1:5.

[0034] (2) Carbonize the ZIF-67 and carbon nanotube composite precursor prepared in step (1): Slowly heat the ZIF-67 and carbon nanotube composite precursor material prepared in step (1) in a vacuum environment to obtain Porous dodecahedral composite intermediate product; the heat treatment includes a heating rate of 3°C / min, a heat treatment ...

PUM

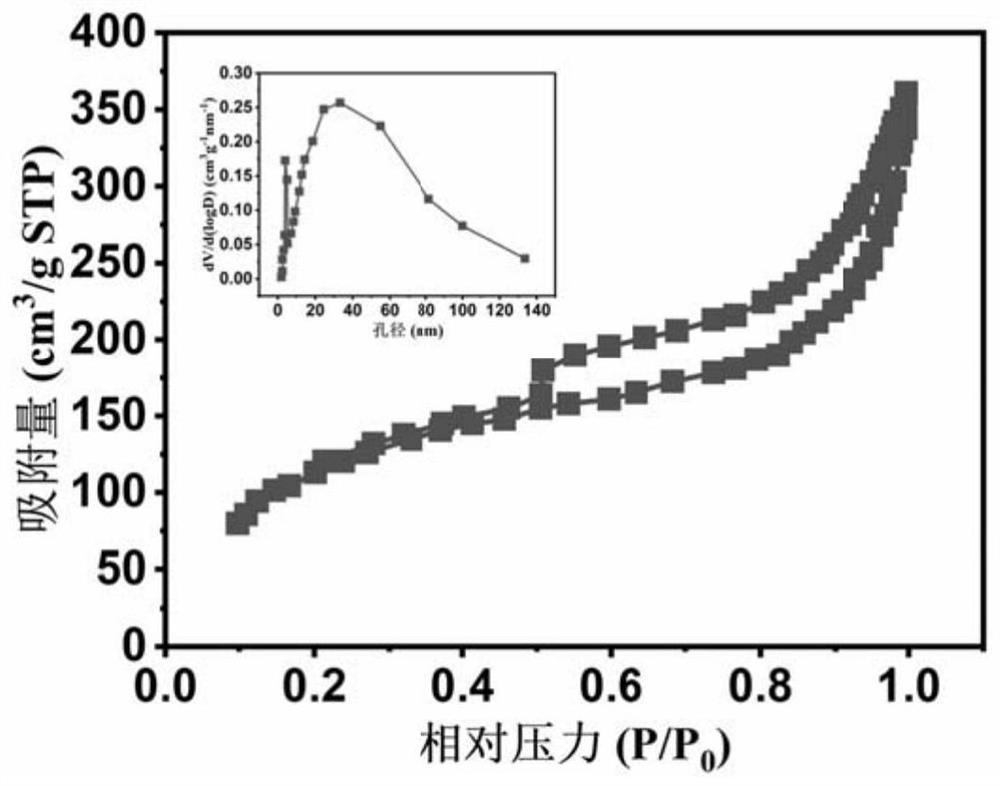

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com