Preparation method of nano flower-like titanium dioxide@bismuth trisulfide electrode material

A technology of bismuth trisulfide and titanium dioxide, applied in titanium dioxide, titanium oxide/hydroxide, chemical instruments and methods, etc., can solve the problems of poor reversibility, reduction, and poor rate performance of electrochemical reactions, and achieve regular morphology Control, reduce volume effect, improve the effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

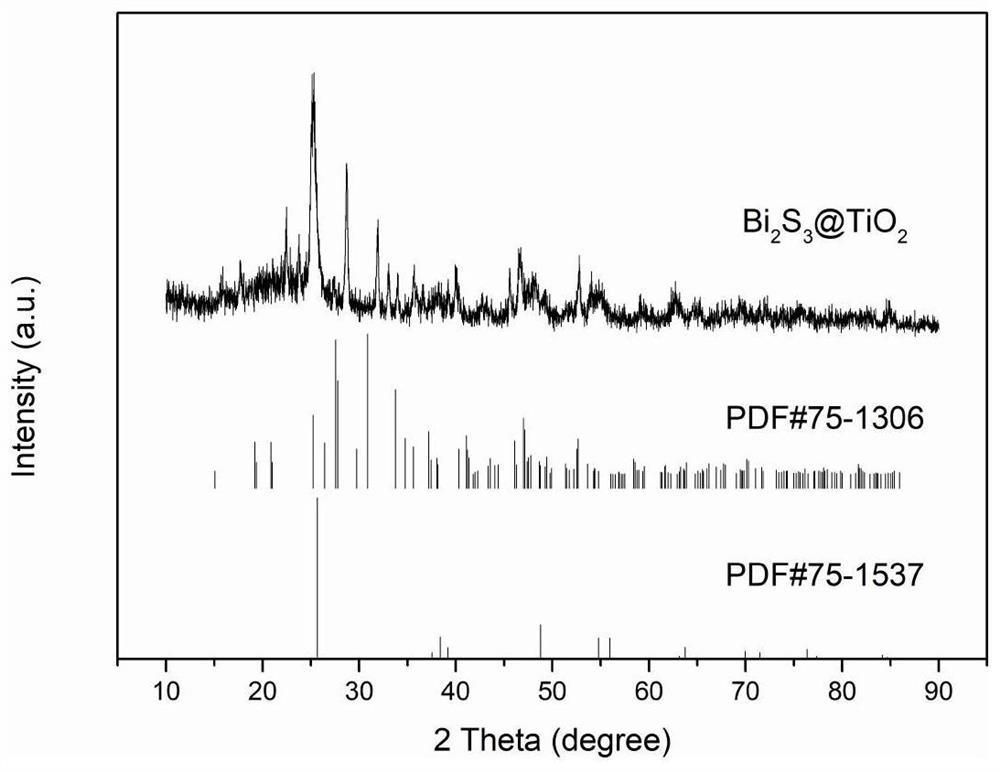

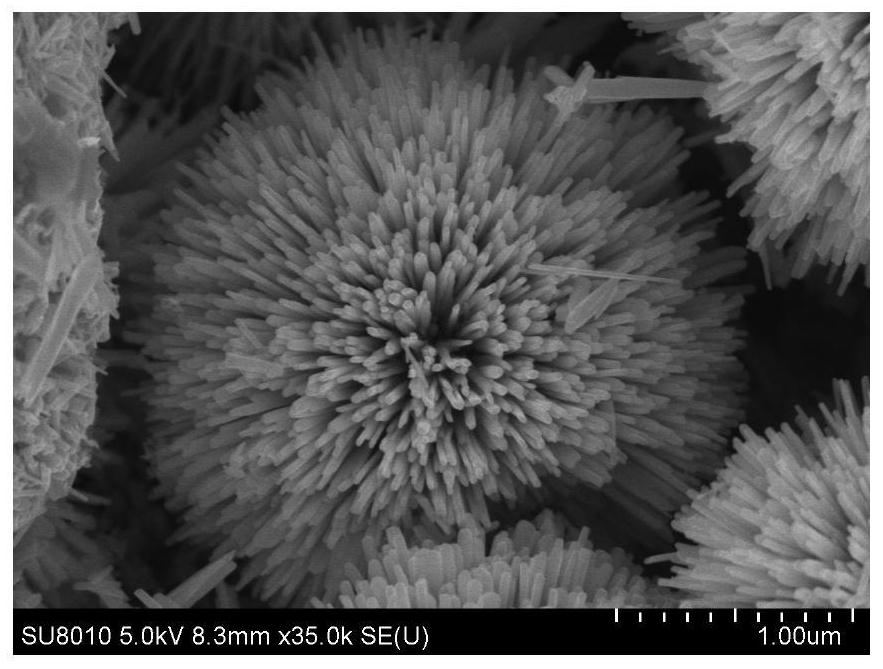

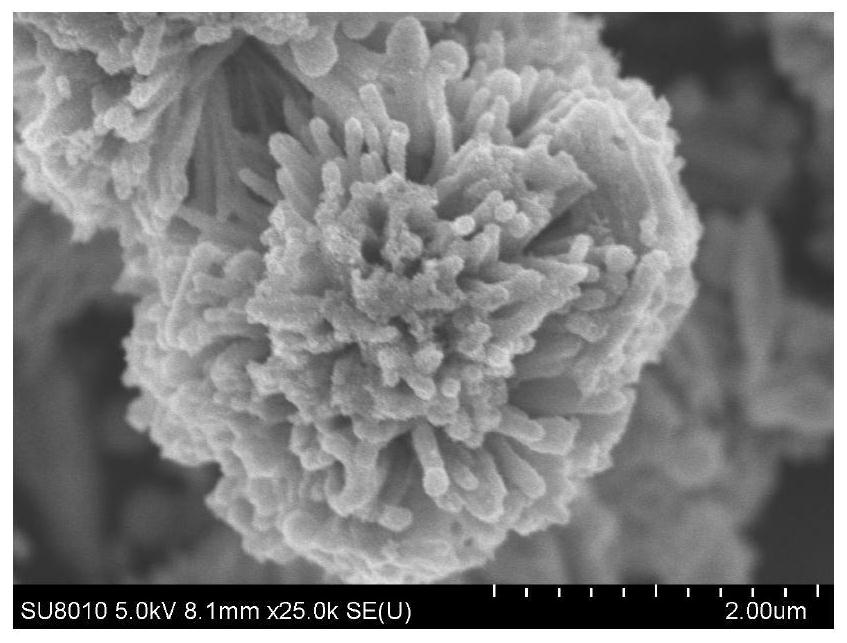

[0026] Dissolve 1 mmol of commercial bismuth chloride in 40 ml of ethylene glycol, and stir ultrasonically for 1 hour until the white particles are completely dissolved; add 2 mmol of thioacetamide, and stir ultrasonically for 1 hour until the particles are completely dissolved; add the above solvent to 100 ml of hydrothermal reaction Kettle, heated at 180°C for 12 hours, and cooled to room temperature; the black hydrothermal reaction product was centrifuged and washed several times (3-4 times), dried in an oven at 60°C for 12 hours, collected for use, and the nano-flower-shaped three Bismuth sulfide; take 0.1 gram of nano-flower-shaped bismuth trisulfide powder (place it in a three-necked flask containing 100 ml of water at 80°C, stir in a water bath for 30 minutes; slowly inject 80 mg of tetrabutyl titanate solution into the above-mentioned three-necked flask ( duration of 5 minutes); after 12 hours in a water bath at 80°C, the gray reaction product was washed by centrifugati...

Embodiment 2

[0028] Dissolve 1 mmol of commercial bismuth chloride in 60 ml of ethylene glycol, and stir ultrasonically for 1 hour until the white particles are completely dissolved; add 3 mmol of thiourea, and stir ultrasonically for 1 hour until the particles are completely dissolved; put the above solvent in a 100 ml hydrothermal reactor, Heat at 200°C for 12 hours, then cool to room temperature; the black hydrothermal reaction product (nano flower-like bismuth trisulfide) is washed by centrifugation for several times (3-4 times), dried in an oven at 60°C for 12 hours, and then collected for use ; Take 0.1 gram of black reaction product (nano flower-like bismuth trisulfide) and place it in a three-necked flask containing 80 milliliters of water at 60° C., stir in a water bath for 30 minutes; slowly inject 100 mg of tetrabutyl titanate solution into the above-mentioned three-necked flask ( duration of 5 minutes); after 24 hours in a water bath at 60°C, the gray reaction product (TiO 2 @B...

Embodiment 3

[0030] Dissolve 1 mmol of commercial bismuth chloride in 40 ml of ethylene glycol, and stir ultrasonically for 1 hour until the white particles are completely dissolved; add 1.5 mmol of sodium sulfide, and stir ultrasonically for 1 hour until the particles are completely dissolved; put the above solvent in a 100 ml hydrothermal reactor , heated at 150°C for 12 hours, and cooled to room temperature; the black hydrothermal reaction product (nano flower-like bismuth trisulfide) was washed by centrifugation for many times (3-4 times), dried in an oven at 60°C for 12 hours, and then collected. Use; take 0.1 g of the black reaction product (nanoflower-like bismuth trisulfide) and place it in a three-necked flask containing 60 ml of water at 70°C, stir in a water bath for 30 minutes; slowly inject 60 mg of tetrabutyl titanate solution into the above-mentioned three-necked flask (duration 5 minutes); after 12 hours in a 70°C water bath, the gray reaction product (TiO 2 @Bi 2 S 3 Nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com