A kind of production method and application of thermophilic fungus mannanase

A technology of mannanase and konjac gum, which is applied in the biological field to achieve the effects of good thermal stability, great application value, and rich variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

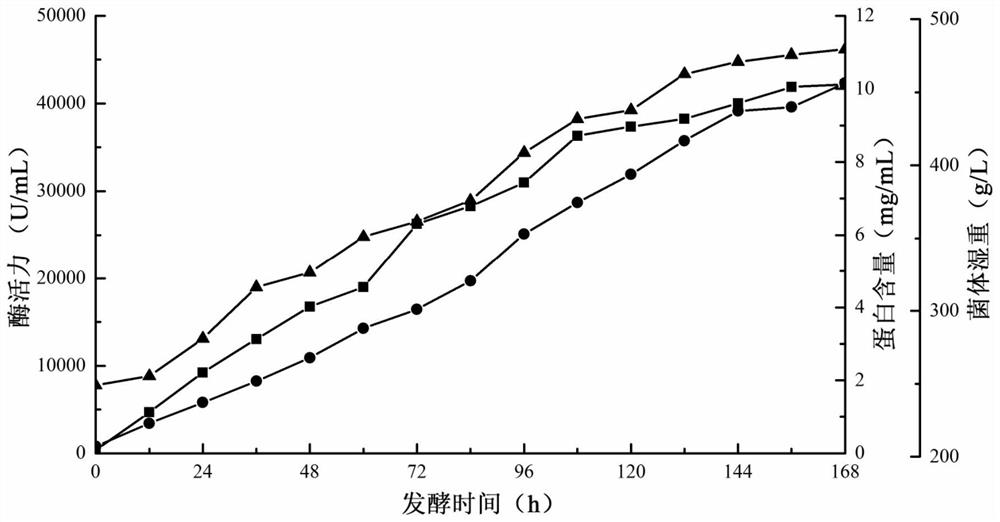

[0080] Embodiment 1, cloning and high-level expression of mannanase gene

[0081] 1. Cloning of the mannanase gene

[0082] Specific primers were used to amplify the mannanase gene from Cladosporium camphorii, and the sequences of the specific primers were as follows:

[0083] Upstream primer: 5′-ATGAAGTTATCATCCTTCGCT-3′;

[0084] Downstream primer: 5'-CTAGCTTGCGTTTCGAGTAGC-3'.

[0085] In the PCR reaction, the cDNA of Malbranchea cinnamonmea S168 was used as a template, and the above primer pair was used as primers, and Ex taq DNA polymerase (Takara Company) was used to amplify. The program was: pre-denaturation at 95°C for 5 minutes; 30 cycles of amplification at 94°C for 30s, 55°C for 30s, and 72°C for 1 min; total extension for 10 minutes. After the PCR product was detected by 1% agarose gel electrophoresis, it was recovered and connected to the pMD-18T vector (Takara Company), transformed into Escherichia coli by heat shock method, and a single colony was selected for ...

Embodiment 2

[0102] Embodiment 2, the purification of mannanase and the determination of enzymatic properties

[0103] 1. Purification of mannanase

[0104] Q-Sepharose FF (Q-Sepharose FF) ion-exchange chromatography: get 10mL of the fermented liquid fermented through the high-density fermentation of Example 1, obtain the supernatant through centrifugation at 10000rpm for 5min, in 20mmol / L Tris-HCl buffer ( pH 8.0) overnight, and loaded on a Q-sepharose column equilibrated with 20mmol / L Tris-HCl buffer (pH 8.0). Elute with 20mmol / L Tris-HCl buffer (pH8.0) for 20min, elute unbound protein, and linearly elute with 20mmol / L Tris-HCl buffer (pH8.0) containing 0-500mmol / L NaCl For protein, the elution time was 100min, and the eluate containing the target protein was combined and then dialyzed overnight with 20mmol / L MOPS buffer (pH7.5).

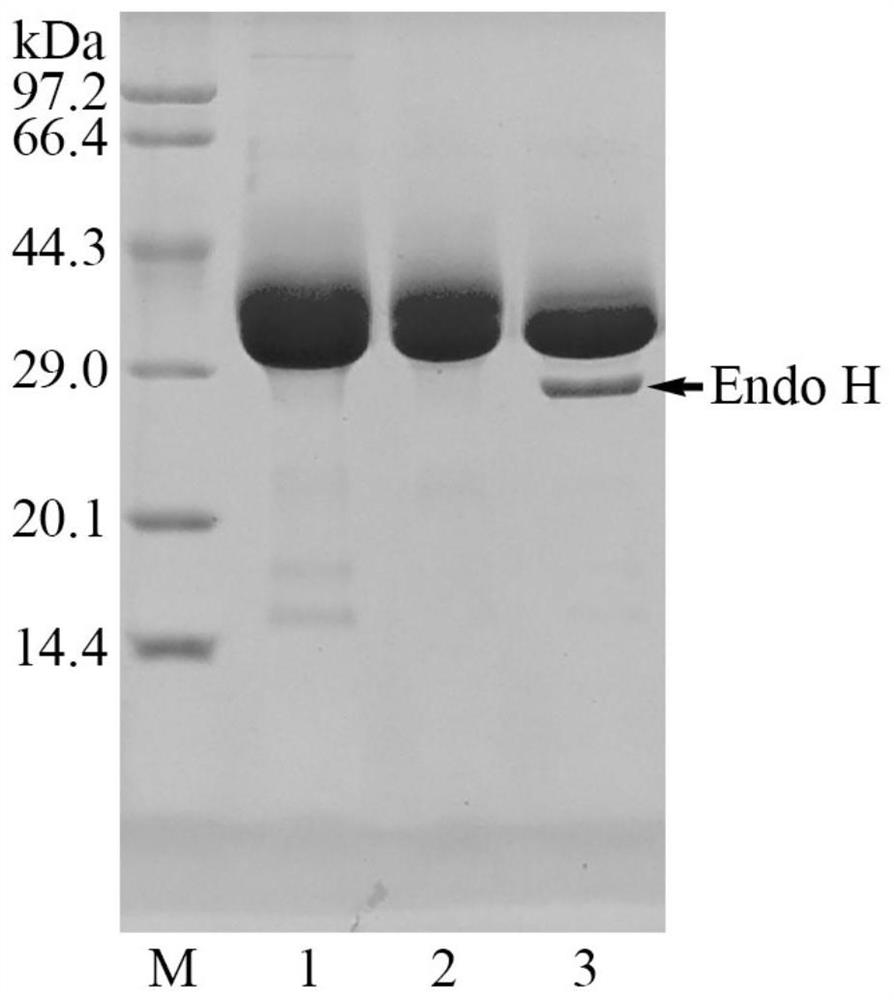

[0105] SDS-PAGE purification diagram as shown figure 2 shown. Wherein, swimming lane 1 is the fermentation supernatant, swimming lane 2 is the pure enzym...

Embodiment 3

[0132] Embodiment 3, hydrolysis different substrate concentration konjac gum

[0133] Weigh 100mL 50mmol / L MOPS buffer solution of pH7.5, add 1g, 5g, 10g, 20g, 30g konjac gum and stir well, add mannanase McMan5A according to the ratio of konjac gum to 200U / g, and place at 70°C It was hydrolyzed for 8 hours, and after enzymolysis, the reaction was terminated in a boiling water bath for 20 minutes to obtain an enzymolysis solution. The viscosity of the enzymolysis solution was measured at 25°C with a DV-1 rotational viscometer. The weight average molecular weight of the product was determined by gel exclusion chromatography. Dilute the product concentration to 10mg / mL with distilled water, centrifuge at 10000rpm for 5min, take the supernatant, pass through a 0.22μm filter membrane and load the sample, the chromatographic column is TSKgel GMPW XL , the column temperature was 35°C, the mobile phase was water, and the flow rate was 0.6mL / min. The molecular weight and molecular w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com