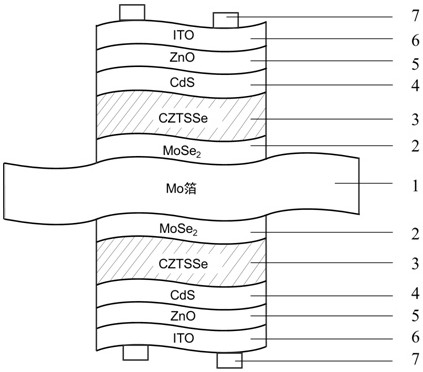

CZTSSe flexible double-sided solar cell and preparation method thereof

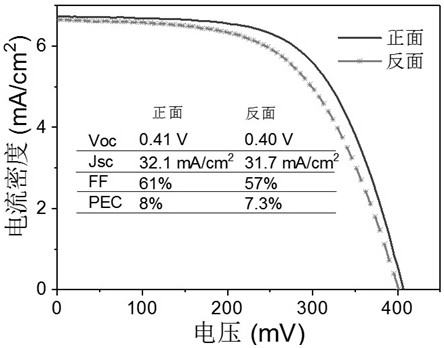

A double-sided solar cell and solar cell technology, applied in the field of solar cells, can solve the problems of lack of process technology, large occupied area, and inability to fully utilize sunlight, etc., to achieve cost savings, reduced occupied area, and improved utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation process of double-sided CZTSSe thin film:

[0031] (1) Add elemental copper, zinc, tin, sulfur, and selenium into the mixture of ethylenediamine and ethylenedithiol in a certain proportion, heat and stir to obtain a uniform and clear CZTSSe precursor solution.

[0032] (2) Transfer the CZTSSe precursor solution to the glove box, drop it onto one side (front) of the flexible molybdenum foil for spin coating, turn it at 3000 rpm for 30s, and then sinter it on a hot stage at 300 degrees to obtain a Thin CZTSSe films.

[0033] (3) Spin-coat the reverse side of the molybdenum foil onto which the CZTSSe precursor solution was dropped, spin at 3000 rpm for 30s, then place the sample in the air, place it on the hot stage for sintering at 300 degrees, and obtain a thin layer of CZTSSe film on the reverse side of the molybdenum foil .

[0034] (4) Repeat the process of spin coating and sintering, alternately deposit CZTSSe film on the front and back of the above fil...

Embodiment 2

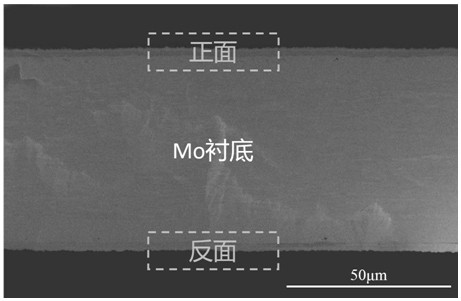

[0036] The specific preparation process of CZTSSe flexible double-sided solar cells:

[0037] (1) Under constant pressure conditions, the molybdenum foil was placed in a mixed solution of methanol (85mL) and concentrated sulfuric acid (15mL) through electrochemical cleaning to remove surface impurities and molybdenum oxide. Then ultrasonically clean with deionized water, isopropanol, and absolute ethanol in sequence, each for 5 minutes, and then blow dry with nitrogen.

[0038] (2) Using precursor solution spin-coating technology, spin-coat CZTSSe precursor solution on both sides of the molybdenum foil substrate, and then obtain a CZTSSe thin film by overhead annealing. Repeat spin-coating and annealing many times to obtain a thickness of 1 μm ~ 4 μm;

[0039] (3) Put the Mo sheet sample with CZTSSe layer and selenium powder into a closed graphite box, place it in a rapid thermal annealing furnace protected by nitrogen, and selenize it at a temperature of 550 °C for 15 min to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com