Preparation method and application of bentonite composite material for adsorbing and degrading site odor substances

A composite material, adsorption and degradation technology, applied in the field of in-situ chemical remediation of organically polluted sites, can solve the problems of few types of commercially available products, short odor diffusion control time, high price, and achieve stable product properties, easy operation and mild reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

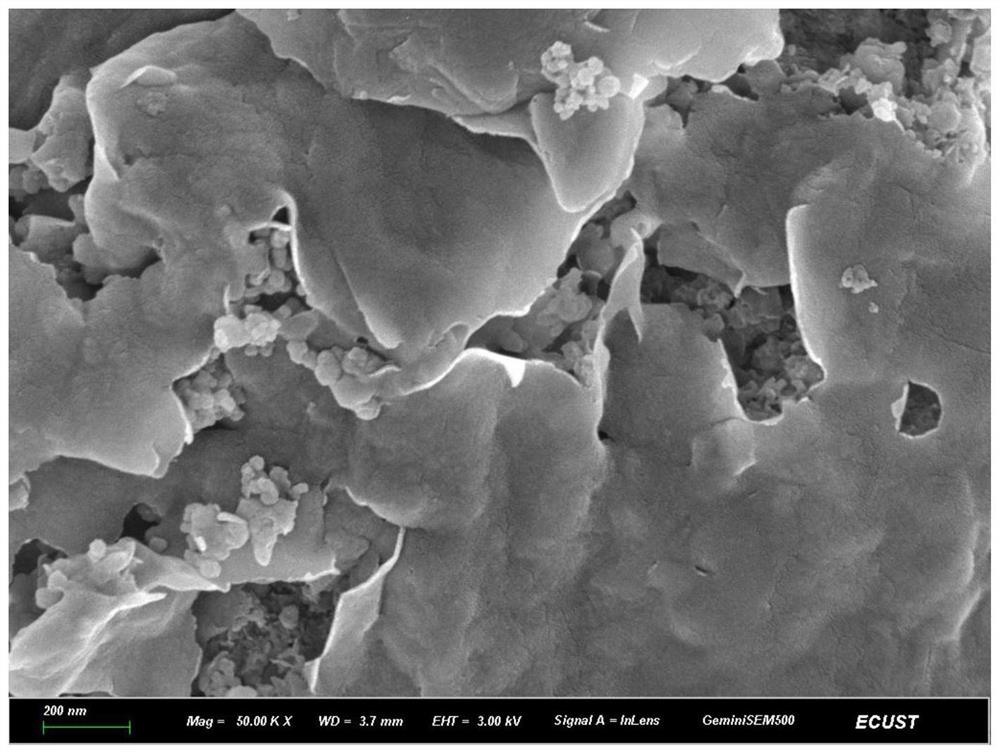

[0028]Preparation of bentonite composite material: raw materials (mass parts) mainly include bentonite (100), cetyltrimethylammonium chloride (5), chitosan (1), calcium chloride (50), hydrogen peroxide (200), cetyltrimethylammonium bromide (0.02), ammonia water (accounting for 5% of the volume fraction of the reaction system). Dissolve 5g of cetyltrimethylammonium chloride in 500mL of distilled water and mix evenly, add 100g of sodium bentonite, and stir at a high speed in a water bath at 60°C until it becomes emulsion; add 1% acetic acid solution containing 1g of chitosan, and ultrasonically After 60 minutes, the product was washed three times with ethanol solution and distilled water; after drying at 102°C, it was ground through a 200-mesh sieve to obtain organically modified bentonite; take 500 mL of cetyltrimethylammonium bromide (0.02 g) aqueous solution , add 50g calcium chloride, ultrasonic 90min, add organic modified bentonite, ultrasonic 120min to obtain mixed solutio...

Embodiment 2

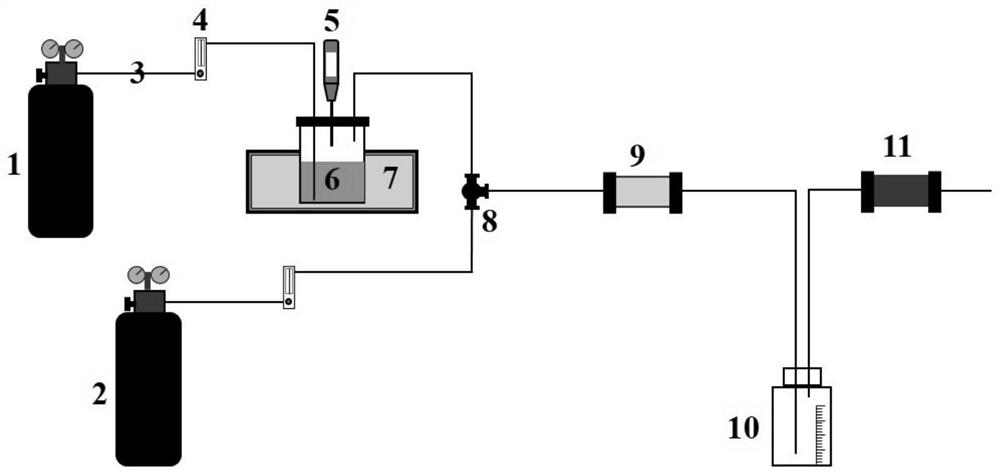

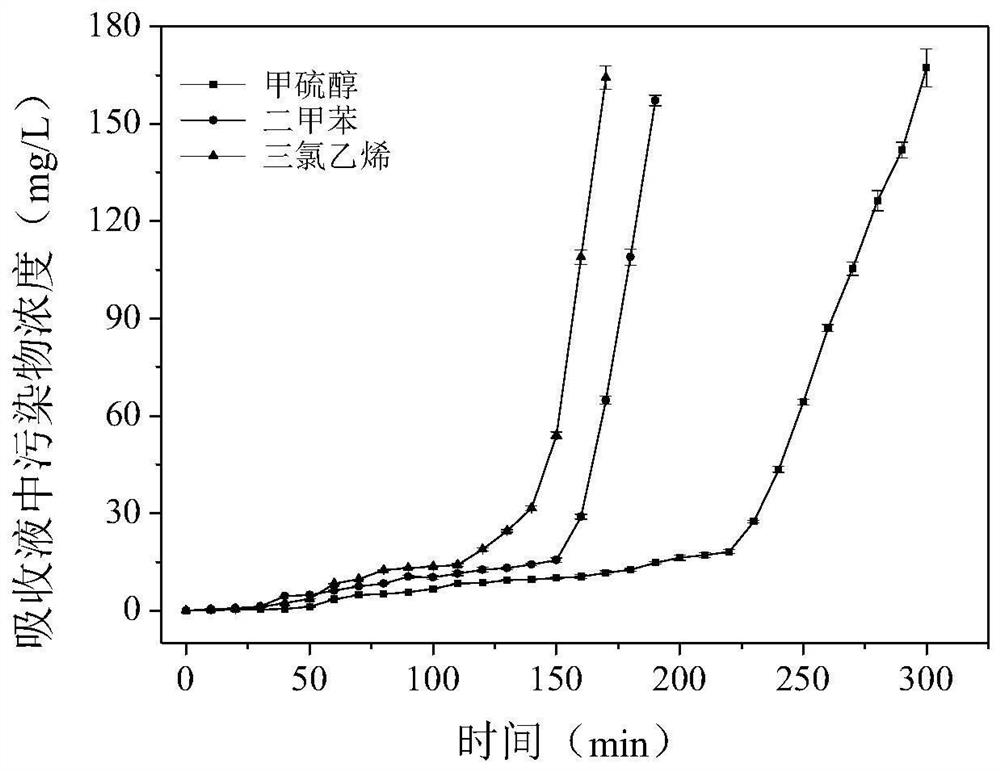

[0033] Verification of the barrier performance of bentonite composite materials for soil odor substances: the preparation method of bentonite composite materials is the same as in Example 1, and the experimental device is shown in Figure 4 . The inner diameter of the experimental device: length 30cm×width 30cm×height 20cm, filled with soil mixed with odorous substances (height 10cm, about 15kg soil, odorous substance release surface 0.09m 2 ), respectively fill in methyl mercaptan (200mg / kg), xylene (200mg / kg), trichlorethylene (200mg / kg) contaminated soil, set the soil moisture content to 25%, and evenly spray 18g of bentonite on the surface of the contaminated soil Composite material (200g / m 2 ). To avoid loss of odorous substances, the experimental setup was sealed with adhesive tape. Turn on the nitrogen gas bottle, pass clean nitrogen gas from one end of the device at a certain gas flow rate, and use a pollutant recovery bottle filled with n-hexane solution (1L) to ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com