Ferroferric oxide nanoparticles as well as preparation method and application thereof

A technology of ferroferric oxide and nanoparticles, which is applied in the field of inorganic nanomaterials, can solve the problems of unusable enzymes, high cost, and high cost of biosensors, and achieve the effect of avoiding precipitation reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

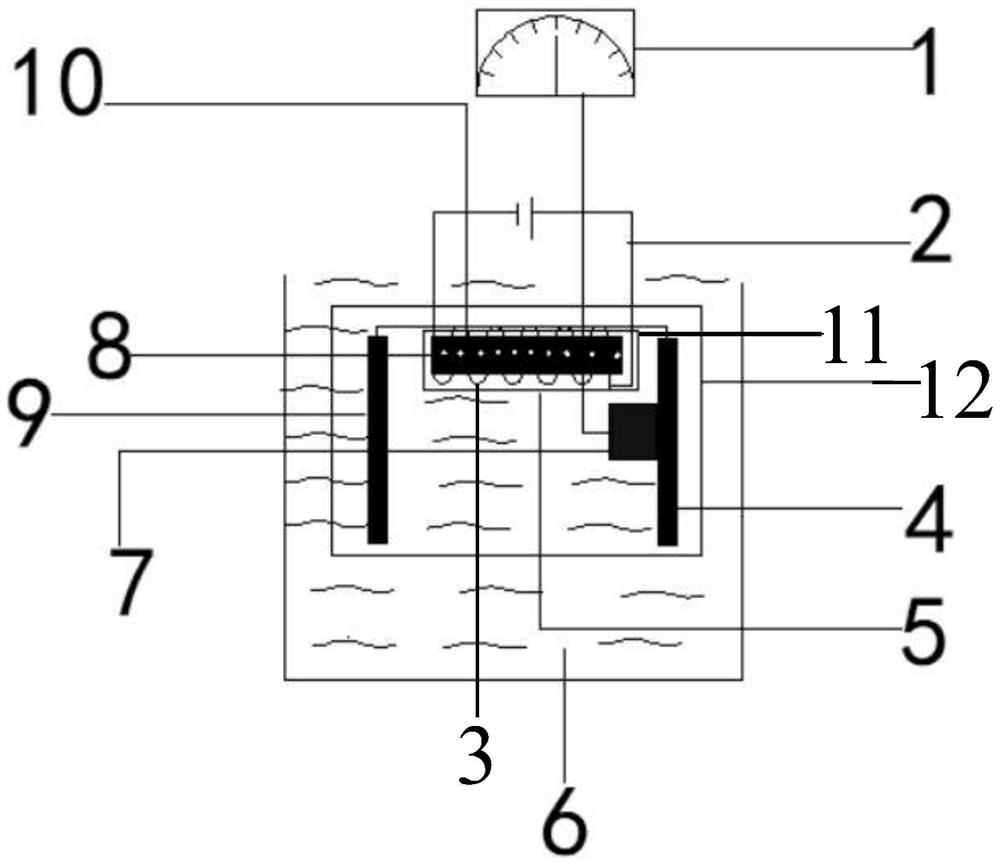

Image

Examples

Embodiment 1

[0088] Embodiment 1: the preparation of ferric oxide nanoparticles

[0089] (1) Take 3.2g FeCl 3 ·6H 2 O, 1.5g FeSO 4 ·7H 2 O was dissolved in a mixed solvent of 10 mL of absolute ethanol and 10 g of glycerin, and 5 g of anhydrous sodium acetate was added as a co-solvent, 25 Hz ultrasonic for 5 min, and stirred at 40 ° C to completely dissolve the solid to obtain solution A;

[0090] (2) Take 10mL 0.0058mol / mL sodium dodecylbenzenesulfonate solution and 5mL n-butanol and mix evenly to obtain a mixing aid, then take 10mL toluene and add it to the mixing aid and mix to obtain a mixture, then drop while stirring Add 3mL of step (1) to obtain solution A, then add 3mL of 4mol / L NaOH solution dropwise while stirring, and stir until the solution becomes transparent and clear to obtain 31mL of solution B;

[0091] (3) Add 0.02g sodium polymethacrylate (purchased from Guangdong Wengjiang Chemical Reagent Co., Ltd., product number: PB063162, CAS number: 54193-36-1) to solution B, th...

Embodiment 2

[0094] Embodiment 2: the preparation of enzyme biosensor

[0095] Preparation of ferric oxide-β-glucosidase:

[0096] (I) Get the iron ferric oxide nanoparticles obtained in 0.1g Example 1, 0.2g PEG4000 (purchased from Shanghai Kaibite Chemical Co., Ltd.), 0.1g FeSO 4 and 0.1g K 2 S 2 o 8 Mix, then add 20mL of ethanol with a concentration of 50% (v / v), then add 20mL of water, stir until completely dissolved, keep the temperature at 25°C, then add 4mL of methyl acrylate for copolymerization reaction for 30min, to obtain a polymerization product;

[0097] (II) washing the polymerized product with ethyl acetate and distilled water subsequently, and then separating it with a magnet to obtain 0.2 g of magnetic particles;

[0098] (Ⅲ) Add 40 mL of 2% (volume fraction) hydrazine hydrate ethanol solution to the magnetic particles (take 2 mL of 80% (v / v) hydrazine hydrate solution, and use 50% (v / v) ethanol solution Dilute the volume to 100mL to obtain), react for 2h, place in a 6...

Embodiment 3

[0107] Before the experiment, the mass of the β-glucosidase on the nanometer ferroferric oxide coupled enzyme microsphere and the self-assembled β-glucosidase electrode was 0.225g; The mass of iron is 0.18g;

[0108] (1) Use the enzyme biosensor prepared in Example 2 to measure the concentration of glucose solution (5mol / L). When in use, adjust the external power supply voltage (i.e. external power supply voltage) to 1v, disconnect or close the switch every 2s, when The display was stable (4.0mol / L), and the applied voltage was adjusted to be 0.5v. After 15s, a total of 100mL of glucose solution was taken out, and the β-glucosidase content in the glucose solution was quantitatively determined by the Bradford method (the Bradford protein concentration assay kit was purchased from Shanghai Biyuntian Biotechnology Co., Ltd., product number P0006; the specific operation steps are carried out according to the instructions), the result: the protease concentration is 2.25μg / mL, that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com