Epoxy structural adhesive and preparation method thereof

A technology of epoxy structural adhesive and epoxy resin, applied in the direction of epoxy resin adhesive, adhesive, adhesive type, etc., can solve the problems of large shrinkage, easy delamination, and lower glass transition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

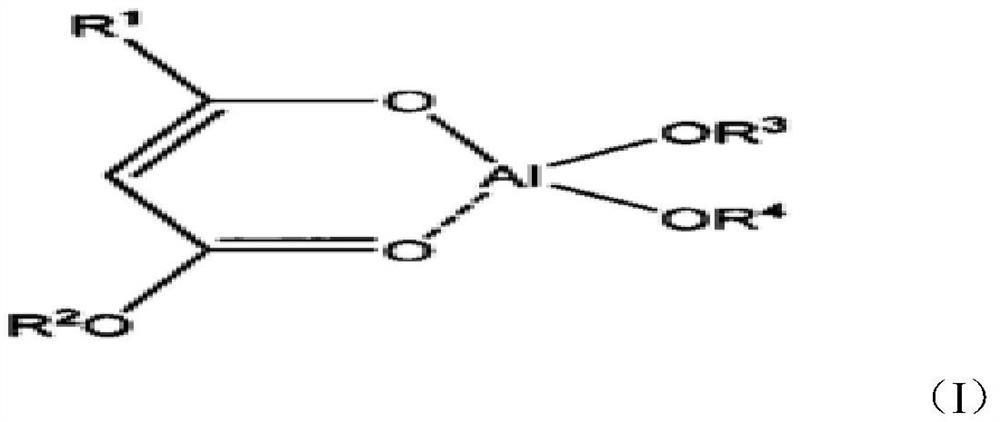

[0077] Synthesis of Aluminate Coupling Agent

[0078] In a four-necked flask equipped with a stirrer, a distillation tube, a gas inlet tube and an internal thermometer, first add 100 g of aluminum isopropoxide and 368.5 g of oleyl acetoacetate, heat the mixture to 80 ° C, and then add 50 drops / min A mixed solution consisting of 285g dioctyl phosphate and 100ml toluene was added dropwise at a speed of 2 The mild flowing gas was decompressed to remove the isopropanol and toluene solvent formed during the reaction. When the desired degree of conversion was achieved, the batch was cooled to 55°C and the pressure depressurized to remove the remaining volatiles. Finally The product mixture was then cooled to room temperature to obtain an aluminate coupling agent.

Embodiment 1

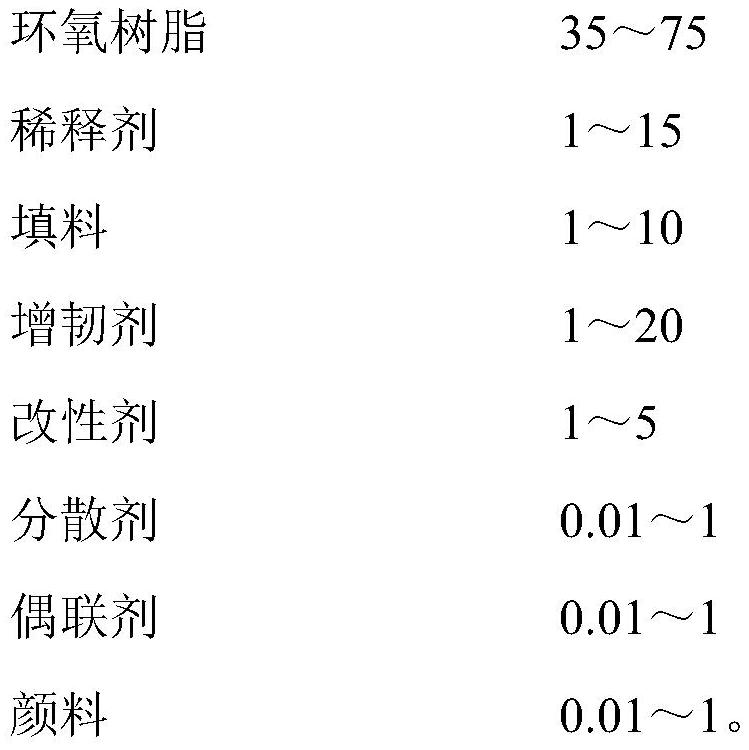

[0080] Preparation of component A:

[0081] 1) Add epoxy resin, diluent and toughening agent to the planetary high-speed mixer, keep vacuum, stir at a high speed of 1500 rpm until mixed evenly, and control the temperature not to exceed 65°C;

[0082] 2) Then add fillers, modifiers, and dispersants in sequence, and continue to stir evenly at a high speed of 250 rpm under vacuum;

[0083] 3) Finally, add the coupling agent and pigment under the protection of nitrogen, adjust the temperature of the circulating water bath to 40-45°C, keep the temperature of the material at 40°C, and stir in a high-speed vacuum at a speed of 500 rpm for 40 minutes.

[0084] 4) Then adjust the rotation speed of the planetary machine to 20 r / min for vacuum degassing for 20 minutes, then pass through a 10-micron stainless steel filter for packaging to obtain component A.

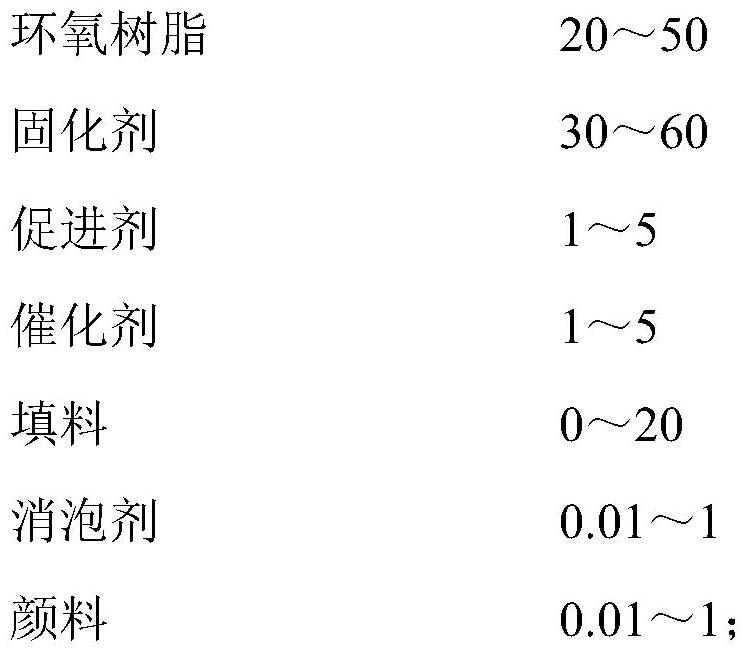

[0085] Preparation of component B:

[0086] 1) Add epoxy resin first under a nitrogen atmosphere, and heat up to 105-120°C for 2...

Embodiment 2

[0095] Preparation of component A:

[0096] 1) Add epoxy resin, diluent and toughening agent into the planetary high-speed mixer, keep vacuum, stir at a high speed of 1800 rpm until mixed evenly, and control the temperature not to exceed 65°C;

[0097] 2) Then add fillers, modifiers, and dispersants in sequence, and continue to stir evenly at a high speed of 300 rpm under vacuum;

[0098] 3) Finally, add coupling agent and pigment under the protection of nitrogen, adjust the temperature of the circulating water bath to 40-45°C, keep the temperature of the material at 40°C, and stir at a speed of 500-850 rpm for 50 minutes under high-speed vacuum.

[0099] 4) Then adjust the rotation speed of the planetary machine to 20-40 rpm for vacuum degassing for 30 minutes, then pass through a 10-micron stainless steel filter for packaging to obtain component A.

[0100] Preparation of component B:

[0101] 1) Add epoxy resin first under nitrogen atmosphere, and heat up to 105-120°C for v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com