Particle-free nickel-based conductive ink and preparation method thereof

A particle-free, conductive ink technology, used in replication/marking methods, inks, printing, etc., can solve the problems of expensive conductive silver ink, low electron mobility, easy oxidation of thin film air, and achieve good adhesion and preparation. The effect of simple process and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a kind of highly stable particle-free nickel-based conductive ink, containing 20% nickel acetate (nickel precursor), 18% ammonia (complexing agent), 2% formaldehyde (reducing agent), 0.1% carboxymethyl Sodium cellulose (organic additive), 0.001% polyvinylpyrrolidone (organic additive), 0.001% gelatin (organic additive), 0.001% Tegoerbyk-1802tps (organic additive), and the balance is ethanol. The preparation method is:

[0051] Dissolve ammonia water in ethanol according to the above ratio, mix well, then add nickel acetate into the mixed solution, stir at 20°C for 3 hours until dissolved, then add formaldehyde and organic additives until completely dissolved. The highly stable particle-free nickel-based conductive ink of this embodiment was obtained by filtration through a microporous membrane (pore diameter of 0.22 μm), with a viscosity of 1.9 mPa·s and a surface tension of 30 mN / m.

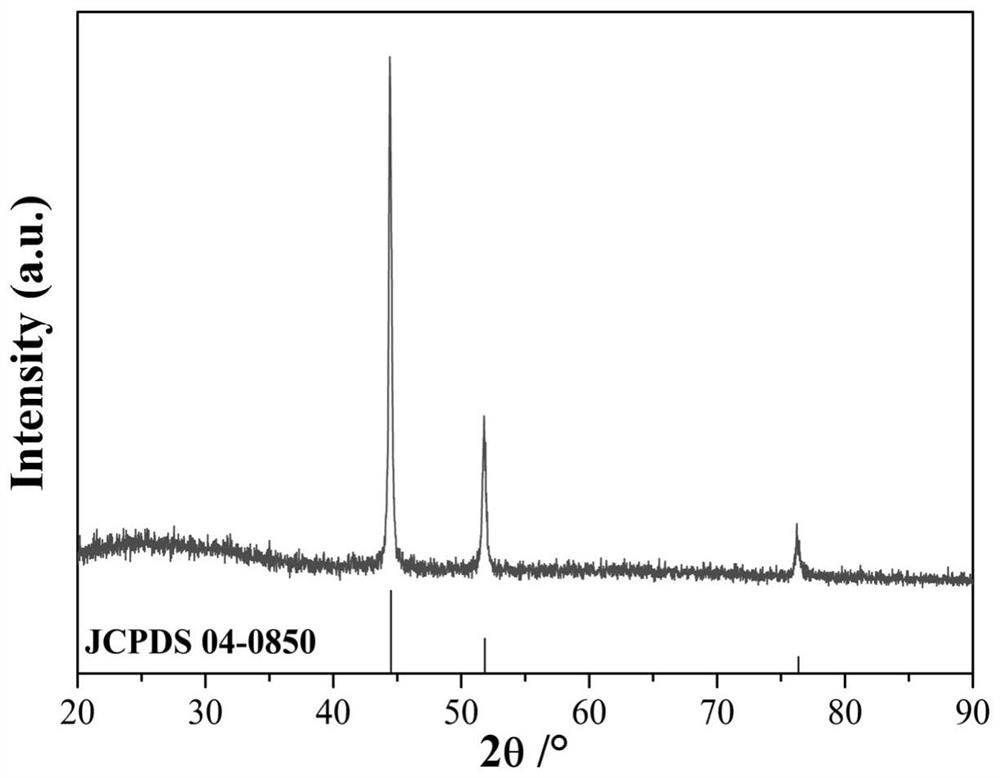

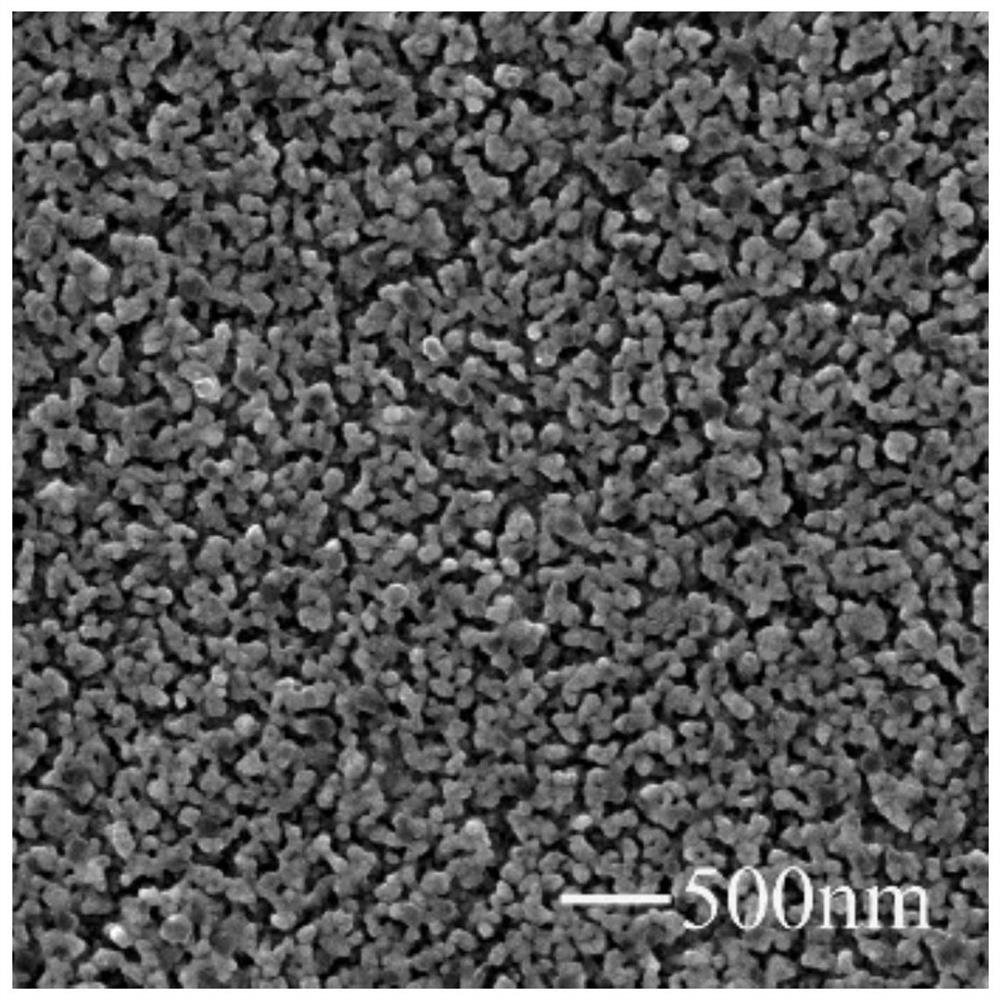

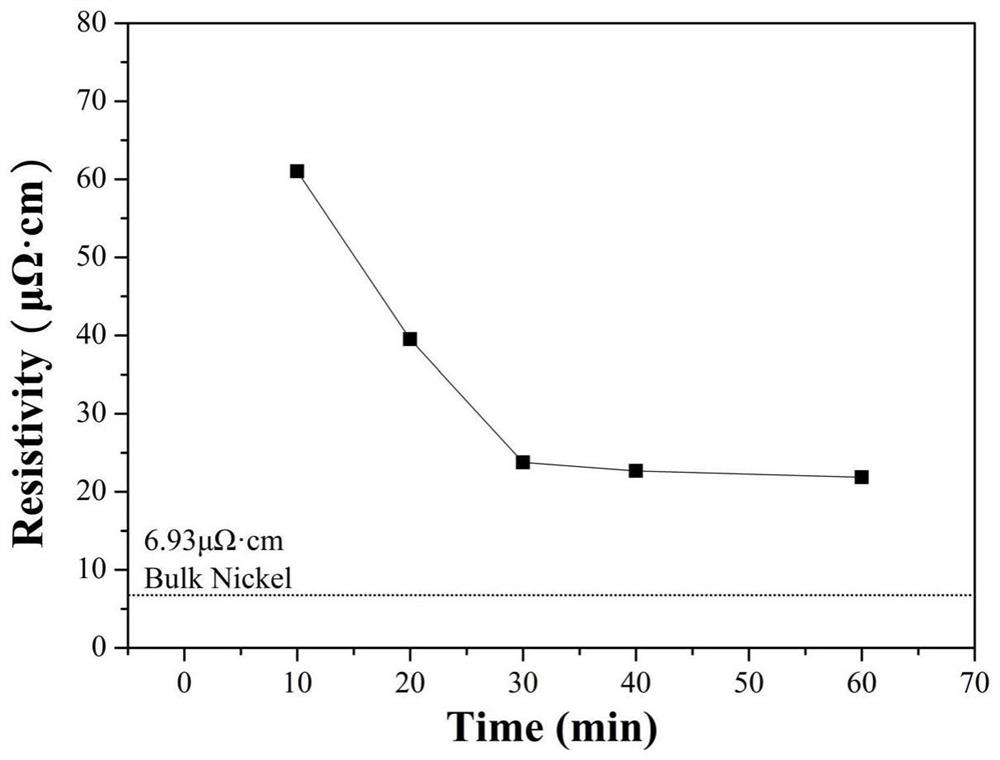

[0052] Take 400 μL of the ink and spin-coat it on a 2cm*2...

Embodiment 2

[0054] This embodiment provides a kind of highly stable particle-free nickel-based conductive ink, containing 35% nickel oxalate (nickel precursor), 26% ethylamine (complexing agent), 2% glycerol (reducing agent), 0.02% Phenolic resin (organic additive), 0.001% polyvinylpyrrolidone (organic additive), 0.001% methylcellulose (organic additive), 0.001% DISPERBYK-2015 (organic additive), and the balance is ethanol. The preparation method is:

[0055] Dissolve ethylamine in ethanol according to the above ratio, mix well, then add nickel oxalate into the mixed solution, stir at 20°C for 3 hours until dissolved, then add glycerol and organic additives until completely dissolved. The highly stable particle-free nickel-based conductive ink of this embodiment was obtained by filtration through a microporous membrane (0.22 μm), with a viscosity of 1.4 mPa·s and a surface tension of 24 mN / m.

[0056] Take 400 μL of the ink and spin-coat it on a 2cm*2cm glass substrate. The suspension co...

Embodiment 3

[0058] This embodiment provides a kind of highly stable particle-free nickel-based conductive ink, containing 40% nickel acetate (nickel precursor), 38% isopropylamine (complexing agent), 7% ethylene glycol (reducing agent), 0.02% Polyvinylpyrrolidone (organic additive), 0.001% agar (organic additive), 0.001% urea (organic additive), 0.001% DISPERBYK-2015 (organic additive), and the balance is ethanol. The preparation method is:

[0059] Dissolve isopropylamine in ethanol solution according to the above ratio, mix well, then add nickel acetate into the mixture, stir at 20°C for 2 hours until dissolved, then add ethylene glycol and organic additives until completely dissolved. The highly stable particle-free nickel-based conductive ink of this embodiment was obtained by filtration through a microporous membrane (0.22 μm), with a viscosity of 3.4 mPa·s and a surface tension of 34 mN / m.

[0060] Take 400 μL of the ink and spin-coat it on a 2cm*2cm glass substrate. The parameters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com