Blood compatible polymer layer and preparation method thereof

A technology of blood compatibility and polymer layer, which is applied in the fields of coating, surgery, medical science, etc., can solve the problem that the hydrophobic property does not achieve the anti-fouling effect, and achieve excellent anti-red blood cell adhesion performance, controllable experimental conditions, Excellent anti-platelet adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

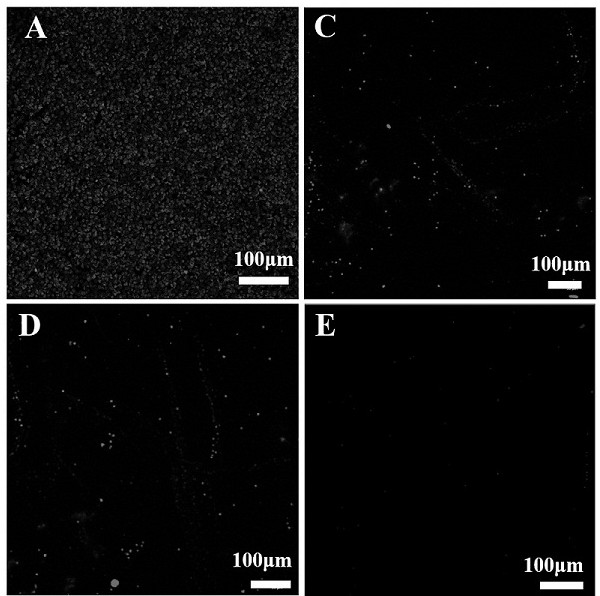

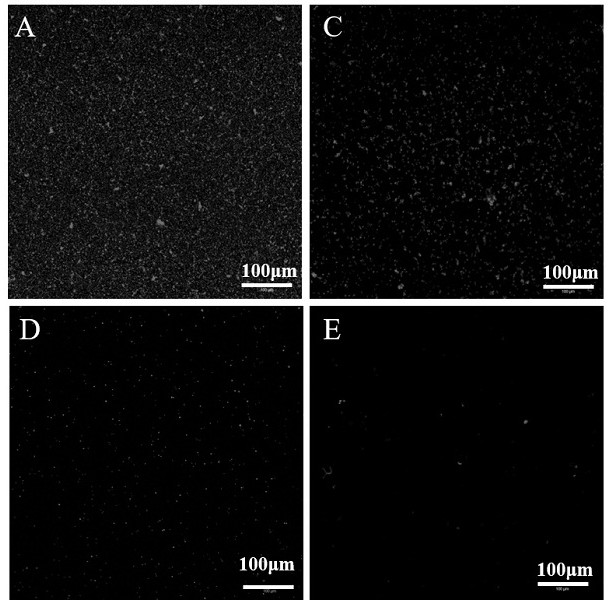

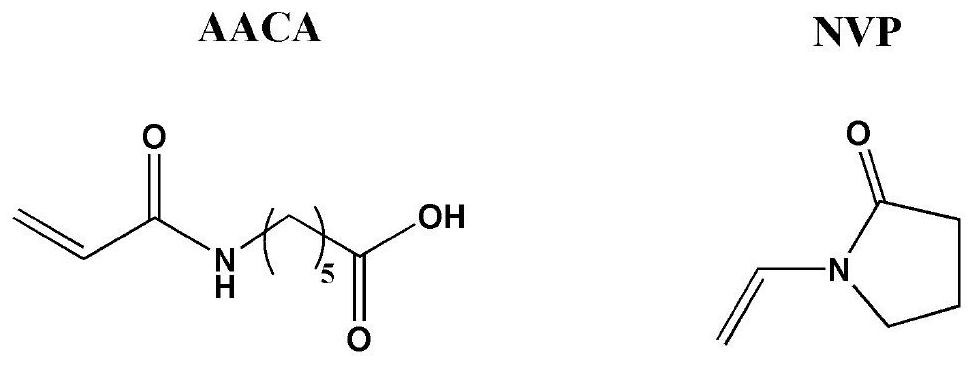

[0047] A method for preparing a blood-compatible polymer layer. Under the condition of ultraviolet light irradiation, the copolymerization reaction of 6-acrylamidocaproic acid and N-vinylpyrrolidone is initiated on the surface of a silanized silicon wafer, and the grafted polymer layer is obtained. Hemocompatible polymer layers on silanized samples, such as Figure 9 As shown, the specific steps are as follows:

[0048] (1) Place the silicon chip in mixed solution I (a mixed solution of concentrated sulfuric acid and hydrogen peroxide, concentrated sulfuric acid is a sulfuric acid solution with a mass fraction of 90%, and hydrogen peroxide is a hydrogen peroxide with a volume fraction of 30%), and heat at 80°C After taking it out for 30 minutes, clean the surface with deionized water, blow dry with high-purity nitrogen (purity 99.999%), and obtain a silicon wafer with surface hydroxylation, named Si-OH, and denoted as A; where concentrated sulfuric acid and hydrogen peroxide ...

Embodiment 2

[0067] A preparation method of a blood-compatible polymer layer, the specific steps are as follows:

[0068] (1) Place the substrate (ceramic) in mixed solution I (a mixed solution of concentrated sulfuric acid and hydrogen peroxide, concentrated sulfuric acid is a sulfuric acid solution with a mass fraction of 98%, and hydrogen peroxide is a hydrogen peroxide with a volume fraction of 30%), and heat Heating at lower temperature for 30min, cleaning the surface with deionized water after taking it out, and drying it with high-purity nitrogen gas (purity 99.999%) to obtain the substrate of surface hydroxylation; the volume ratio of concentrated sulfuric acid and hydrogen peroxide in the mixed solution I is 3: 1;

[0069] (2) carrying out silanization treatment to the surface hydroxylated substrate obtained in step (1) to obtain a silanized substrate;

[0070] The process of specific silanization treatment is: the surface hydroxylated substrate obtained in step (1) is placed in ...

Embodiment 3

[0075] A preparation method of a blood-compatible polymer layer, the specific steps are as follows:

[0076] (1) Put the substrate (glass) in the mixed solution I (a mixed solution of concentrated sulfuric acid and hydrogen peroxide, where the concentrated sulfuric acid is a sulfuric acid solution with a mass fraction of 98%, and the hydrogen peroxide is a hydrogen peroxide with a volume fraction of 30%). After heating for 32min, take it out, clean the surface with deionized water, and dry it with high-purity nitrogen gas (purity 99.999%) to obtain a hydroxylated substrate on the surface; the volume ratio of concentrated sulfuric acid and hydrogen peroxide in the mixed solution I is 3: 1;

[0077] (2) carrying out silanization treatment to the surface hydroxylated substrate obtained in step (1) to obtain a silanized substrate;

[0078] The process of specific silanization treatment is: the surface hydroxylated substrate obtained in step (1) is placed in mixed solution II (sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com