Organic electroluminescent device and display device

An electroluminescent device and electroluminescent technology, which are applied to electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of substandard blue color coordinates, low exciton utilization, blue damage, etc., and achieve good color purity, The effect of suppressing energy loss and reducing efficiency roll-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

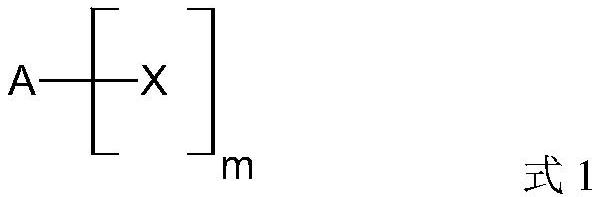

[0097] The invention also provides a preparation method of the organic electroluminescence device, which comprises sequentially depositing an anode, a hole transport region, a light-emitting layer, an electron transport region and a cathode on a substrate, and then encapsulating. Among them, when preparing the light-emitting layer, the evaporation rate of the TTA material and the evaporation rate of the resonant TADF material are adjusted to make the dye reach a preset doping ratio by using a multi-source co-evaporation method. The light-emitting layer is formed by co-evaporating the source and the resonant TADF material source. The deposition methods of the anode, the hole transport region, the electron transport region and the cathode are the same as the existing methods in the art.

[0098] An embodiment of the present invention also provides a display device, which includes the organic electroluminescent device as provided above. Specifically, the display device may be a ...

Embodiment 1

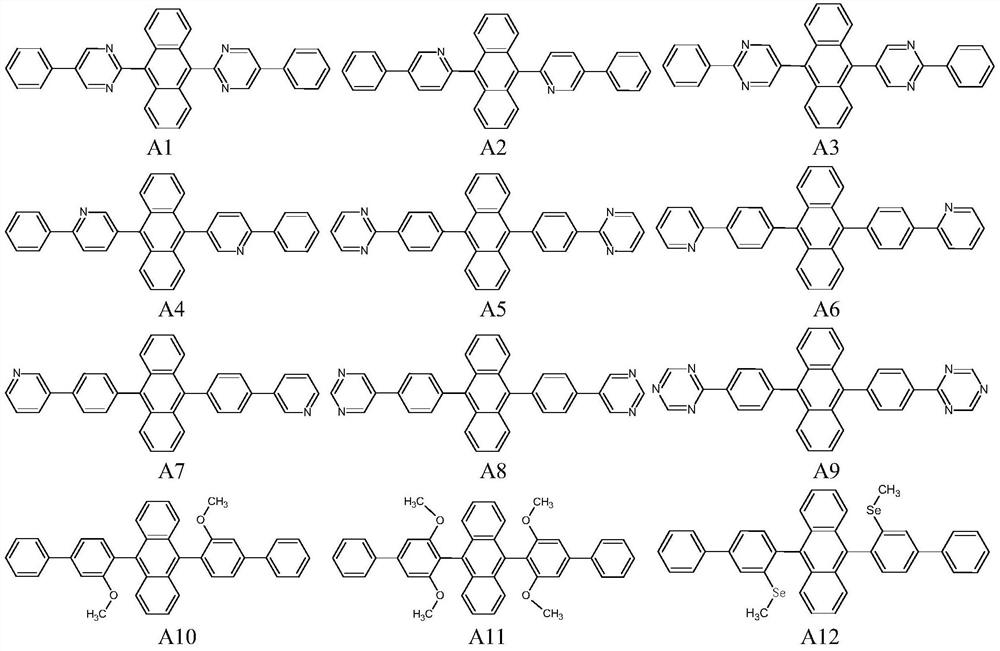

[0103] Synthesis Example 1: Synthesis of Compound A4

[0104]

[0105] Under the protection of argon, 5-bromo-2-phenylpyridine (10g) was dissolved in ultra-dry tetrahydrofuran (200mL) solution, then n-butyllithium (2.5M, 17mL) was slowly added at -80°C into the above solution. Subsequently, anthracene-9,10-dione (3.4 g) was added in one portion. The resulting mixture was stirred for 2 hours, during which time the temperature was raised to 20°C. Subsequently, cold water (100 mL) was added and the organic phase was separated. The aqueous phase was extracted with ethyl acetate (100 mL). The organic portion was dried over magnesium sulfate and the volatiles were removed in vacuo to leave a foamy solid. Potassium iodide (14 g), sodium hypophosphite (10 g) and acetic acid (150 mL) were added to the solid, and the mixture was heated to reflux for 2 h. After cooling, the precipitate was collected and washed with copious THF / H2O (7:3). After drying, 3.4 g of yellow compound 1 ...

Embodiment 2

[0108] Synthesis Example 2: Synthesis of Compound A421

[0109]

[0110] Under the protection of argon, 9,10-bis(3-bromophenyl)anthracene (5.36g), pyridine-3-boronic acid (3.10g), palladium chloride (PdCl 2 , 0.266g), triphenyl phosphite (0.786g), potassium carbonate (12.4g), toluene (166mL), ethanol (120mL) and distilled water (153mL) were sequentially added into a glass flask. The reaction mixture was heated at reflux for 5 h, then the organic portion was separated. The volatiles were removed in vacuo to leave a gray residue which was purified by column chromatography on silica gel using petroleum ether / ethyl acetate (1:1) as eluent. 3.7 g of white compound A421 are obtained. The compound was obtained by H NMR spectroscopy ( 1 HNMR) and high resolution mass spectrometry (HRMS) are characterized as follows:

[0111] 1 H NMR (600MHz, CDCl 3 -d6,δ):8.97(s,2H),8.61(d,J=7.2Hz,2H),7.97(d,J=12.4Hz,2H), 7.81(s,2H),7.78–7.74(m, 8H), 7.56(t, J=10Hz, 2H), 7.39–7.37(m, 6H);

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com