MY preparation bio-organic fertilizer and preparation method thereof

A bio-organic fertilizer and preparation technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, organic fertilizers, etc., can solve the problem of the survival of microbial flora and the difficulty in controlling the survival amount, reduce the fertilizer efficiency of organic fertilizers, and increase the production cost of organic fertilizers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

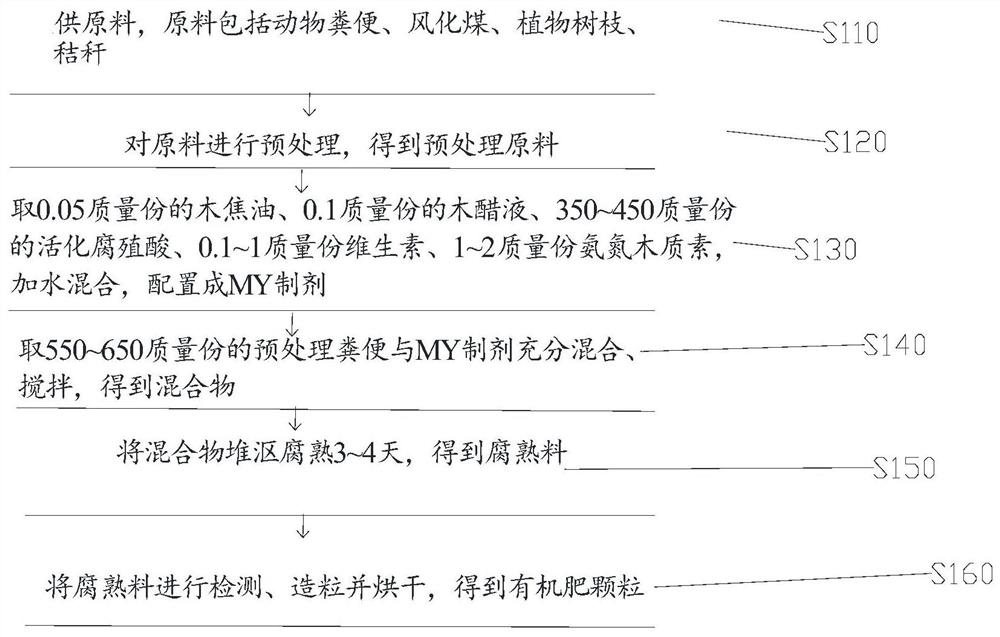

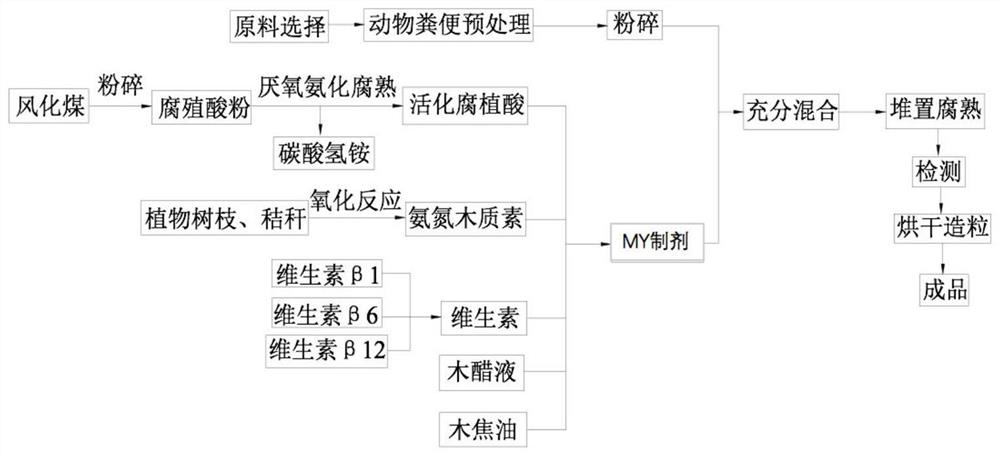

[0024] Such as figure 1 As shown, the application provides a flow chart of a preparation method of MY preparation bio-organic fertilizer, the method comprising:

[0025] Step S110, providing raw materials, including animal manure, weathered coal, plant branches, straw,

[0026] Step S120, pretreating the raw material to obtain the pretreated raw material, the preprocessing includes:

[0027] Detect the heavy metal content of animal feces, select non-polluting animal feces, dehydrate, remove impurities, and pulverize non-polluted animal feces to obtain pretreated feces, pulverize weathered coal to obtain humic acid powder, add humic acid powder Ammonium bicarbonate is decomposed by anaerobic ammoniation to obtain activated humic acid, and the plant branches and straw are oxidized to obtain ammonia nitrogen lignin.

[0028] Step S130, in parts by mass, take 0.04-0.06 parts of wood tar, 0.09-0.11 parts of wood vinegar, 350-450 parts of activated humic acid, 0.1-1 part of vitami...

Embodiment 1

[0042] Provide raw materials, raw materials include animal manure, weathered coal, plant branches, straw, pretreat the raw materials to obtain pretreated raw materials,

[0043] Pretreatment includes: detection of heavy metal content in animal feces, selection of non-polluting animal feces, dehydration, removal of impurities, and crushing of non-polluting animal feces to obtain pretreated feces, pulverization of weathered coal to obtain humic acid powder, and removal of humic acid powder. Ammonium bicarbonate is added to the acid powder for anaerobic ammonification and decomposing to obtain activated humic acid, which is oxidized to plant branches and straw to obtain ammonia nitrogen lignin.

[0044] In terms of parts by mass, take 0.04 parts of wood tar, 0.09 parts of wood vinegar, 350 parts of activated humic acid, 0.1 part of vitamins, and 1 part of ammonia nitrogen lignin, mix them with water, and configure them into MY preparations. Take 650 parts of The pretreated feces ...

Embodiment 2

[0048] Provide raw materials, raw materials include animal manure, weathered coal, plant branches, straw, pretreat the raw materials to obtain pretreated raw materials,

[0049] Pretreatment includes: detection of heavy metal content in animal feces, selection of non-polluting animal feces, dehydration, removal of impurities, and crushing of non-polluting animal feces to obtain pretreated feces, pulverization of weathered coal to obtain humic acid powder, and removal of humic acid powder. Ammonium bicarbonate is added to the acid powder for anaerobic ammonification and decomposing to obtain activated humic acid, which is oxidized to plant branches and straw to obtain ammonia nitrogen lignin.

[0050] In terms of parts by mass, take 0.06 parts of wood tar, 0.11 parts of wood vinegar, 450 parts of activated humic acid, 1 part of vitamins, and 2 parts of ammonia nitrogen lignin, mix with water, and configure MY preparations. Take 550 parts of The pretreated feces are fully mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com