Biodegradable lubricating grease composition and preparation method thereof

A lubricating grease composition and biodegradation technology, applied in the field of lubricating grease, can solve the problem of unsatisfactory and rare degradation of lubricating grease, and achieve excellent anti-oxidation effect, excellent mechanical stability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

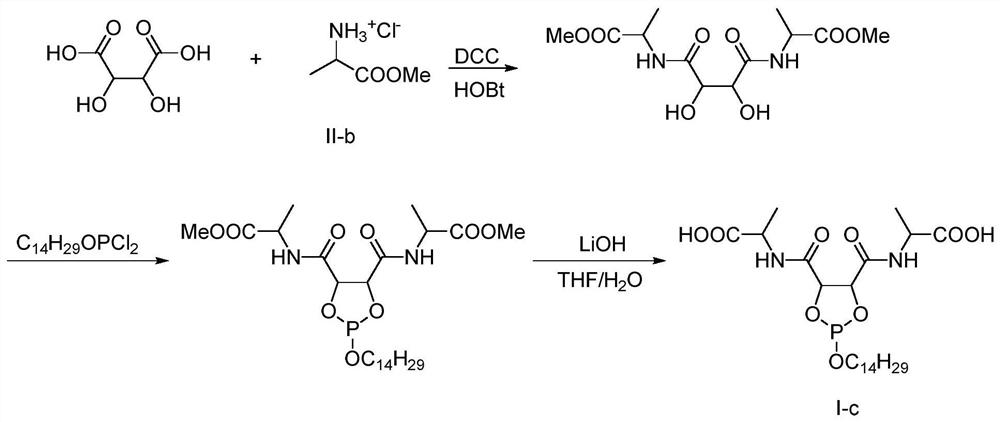

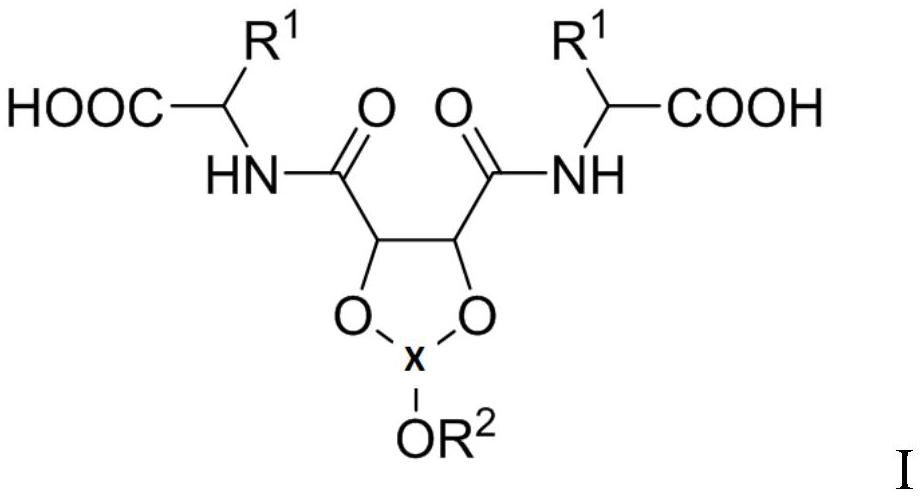

[0044] The present invention also provides a preparation method of the above-mentioned compound of formula I and a method of preparing a lubricating grease composition by using the compound of formula I.

[0045] The preparation method of formula I compound comprises the steps:

[0046] (1) tartaric acid and amino acid ester hydrochloride, that is, the following formula II compound is mixed in the first solvent to carry out a reaction, that is, the first intermediate product is obtained by amidation reaction, wherein R 3 Be methyl, ethyl, tert-butyl or benzyl, for example the compound of formula II can be L-valine methyl ester hydrochloride, L-alanine methyl ester hydrochloride, L-alanine ethyl ester salt salt, L-valine ethyl ester hydrochloride, etc.

[0047]

[0048] In some embodiments, the first solvent is selected from one of dichloromethane, chloroform, acetone, ethyl acetate, N,N-dimethylformamide (DMF), dimethylsulfoxide (DMSO) and acetonitrile or more, preferably...

preparation example 1

[0070] This preparation example is used to illustrate the biodegradation accelerator of the present invention, that is, 2,2'-((2-tetradecyloxy)-1,3,2-dioxaphospholane-4,5-di Carbonyl)-diamino-dipropionic acid (see structural formula I-c) synthetic process.

[0071]

[0072] 1) Add 100mL DMF, tartaric acid (33.3mmol, 5g), L-alanine methyl ester hydrochloride (73.2mmol, 10.21g), 1-hydroxybenzotriazole (79.9mmol, 10.8 g), pyridine (8 mL), cooled to 0°C, added DCC (79.9 mmol, 16.5 g), and reacted overnight. The reaction mixture was suction-filtered, the solid was washed with 300 mL of ethyl acetate, the organic phases were combined, washed twice with saturated sodium bicarbonate solution, twice with 10% hydrochloric acid solution, once with saturated brine, dried over anhydrous magnesium sulfate for 2 h, filtered, Spin dry to obtain a white solid.

[0073] 2) Phosphorus trichloride (40mmol, 5.48g) was dissolved in 5mL of n-hexane, cooled to 4°C, triethylamine (40mmol, 4.04g) ...

Embodiment 1

[0081] In this embodiment, each raw material component is: lubricating base oil (500SN, Thailand) 828g (viscosity at 100°C is 10.9mm 2 / s), lithium hydroxide 8.3g, dodecyl hydroxystearic acid 103.5g; 2,6-di-tert-butyl-p-cresol 12g; barium petroleum sulfonate 9g; dialkyl dithiocarbamate 8g; The biodegradation accelerator 8g of preparation example 1;

[0082] First, take 500g of base oil and 103.5g of lauryl hydroxystearic acid into the fat making kettle, mix and stir evenly. When the temperature rises to 88°C, add 80.7g of lithium hydroxide aqueous solution (including 8.3g of lithium hydroxide and 72.4g of water) to carry out saponification reaction for 30min;

[0083] Then, raise the temperature to 130°C for dehydration reaction, add 12g of 2,6-di-tert-butyl-p-cresol and continue to heat up to 215°C for 15 minutes of high-temperature refining;

[0084] After high-temperature refining, add the remaining 278g of base oil and cool down to 120°C, then add 9g of barium petroleum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com