Method for reducing selenite through liquid-phase catalytic hydrogenation

A liquid-phase catalysis and selenite technology, applied in chemical instruments and methods, catalyst activation/preparation, reduced water/sewage treatment, etc., can solve the problems of active component loss, catalyst deactivation, surface pollution, etc., to achieve Improved stability, simple synthesis method, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The coating structure Pt catalyst of described liquid phase hydrogenation reduction Se (IV) is prepared as follows:

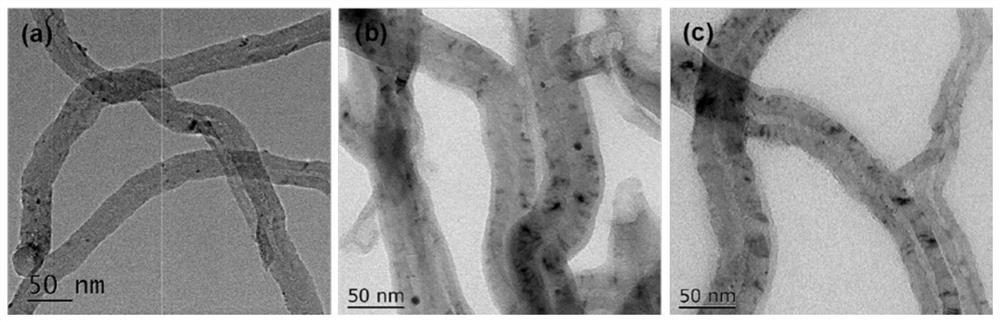

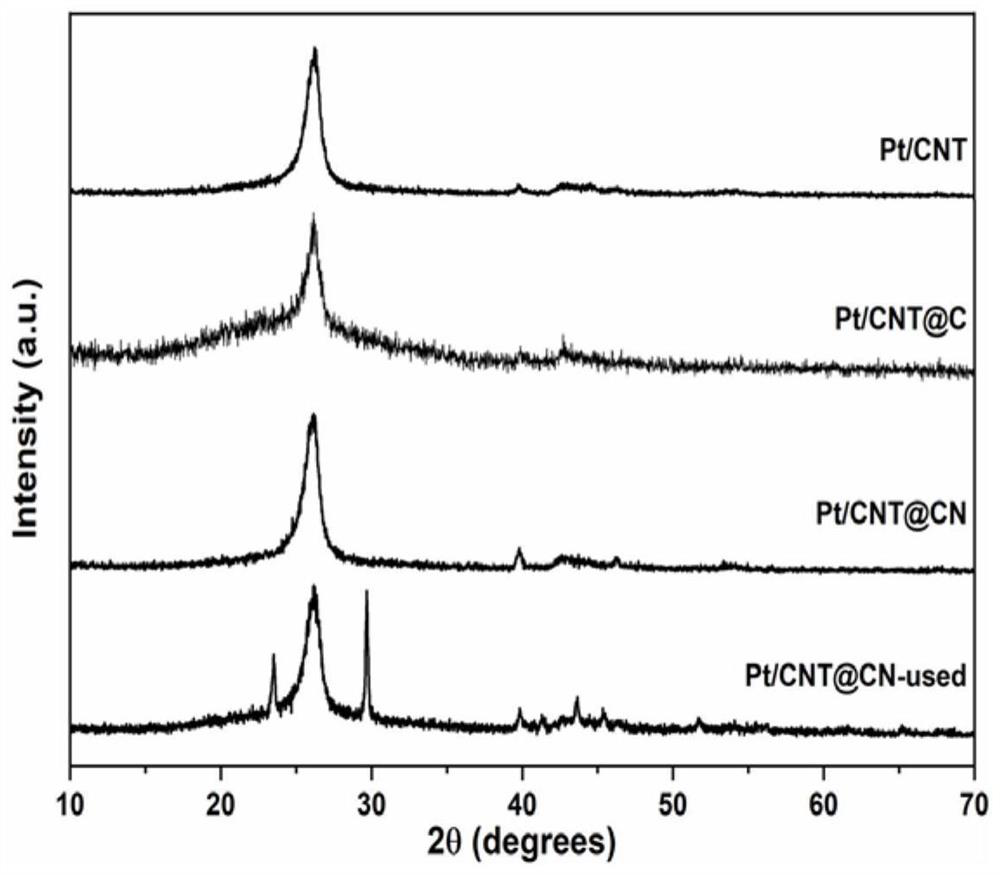

[0042] (1) Firstly, the supported precursor catalyst Pt / CNT was obtained by impregnation method, and the multi-walled carbon nanotube (CNT) and chloroplatinic acid solution were mixed and stirred, evaporated to dryness in a water bath, and N 2 Baked at 300°C under atmosphere, H 2 Reduction at 200°C for 2h under the condition to obtain Pt / CNT, wherein the Pt loading is 0.76wt.%. The transmission electron microscope image of Pt / CNT is as follows figure 1 As shown in (a), it can be seen that the noble metal Pt particles are uniformly dispersed on the surface of the multi-walled carbon nanotubes. According to the statistics, the average particle size of the noble metal Pt is about 2.96nm.

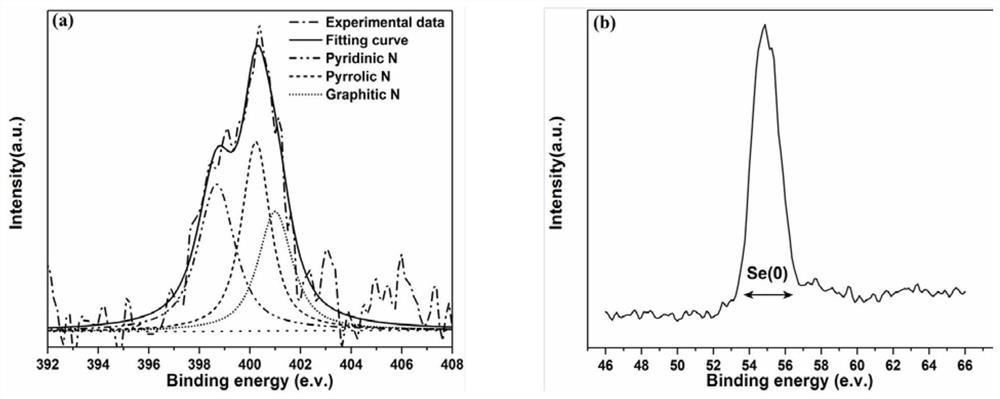

[0043] (2) Add 1g of Pt / CNT to 50mL of absolute ethanol containing 0.4mL of aniline and 10mL of 1M hydrochloric acid. After fully stirring, add 5mL of 1M ammonium persu...

Embodiment 2

[0053] The Pt / CNT, Pt / CNT@C, and Pt / CNT@CN catalysts prepared above were used for the liquid-phase catalytic reduction of Se(IV). The catalyst concentration was 0.125g / L, the initial concentration of Se(IV) was 30ppm, and the hydrogen flow rate was 200mL / min. The reaction was carried out in 10mM HAc-NaAc buffer salt with a pH of 4.75, and the reaction was carried out at room temperature and pressure for 2h. Response curve such as Figure 6 It can be seen that the catalytic performance of the catalyst Pt / CNT@CN coated with the heteronitrogen carbon layer is the highest, indicating that the carbon layer doped with nitrogen can improve the catalytic activity of the catalyst.

Embodiment 3

[0055] The catalyst Pt / CNT@CN for liquid phase hydrogenation reduction of Se(IV) was prepared according to the method in Example 1. The most catalytically active catalyst, Pt / CNT@CN-600, was used for the liquid-phase hydrogenation reduction reaction of Se(IV), with concentrations of 0.05g / L, 0.075g / L, 0.125g / L and 0.15g / L, respectively, The initial concentration of Se(IV) was 30ppm, the hydrogen flow rate was 200mL / min, and the reaction was carried out in 10mM HAc-NaAc buffer salt with pH 4.75. Response curve such as Figure 7 As shown in (a), as the catalyst concentration increases, the time required for Se(IV) to be completely reduced gradually decreases, but from Figure 7 (b) It can be seen that the initial activity of the catalyst is basically maintained at about 2300 mg / (L g cat h), indicating that there is no mass transfer resistance in the reaction system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com