Denitration catalyst with low SO2/SO3 conversion rate and preparation method thereof

A denitrification catalyst, SO3 technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problems of catalyst denitrification activity reduction, air preheater influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

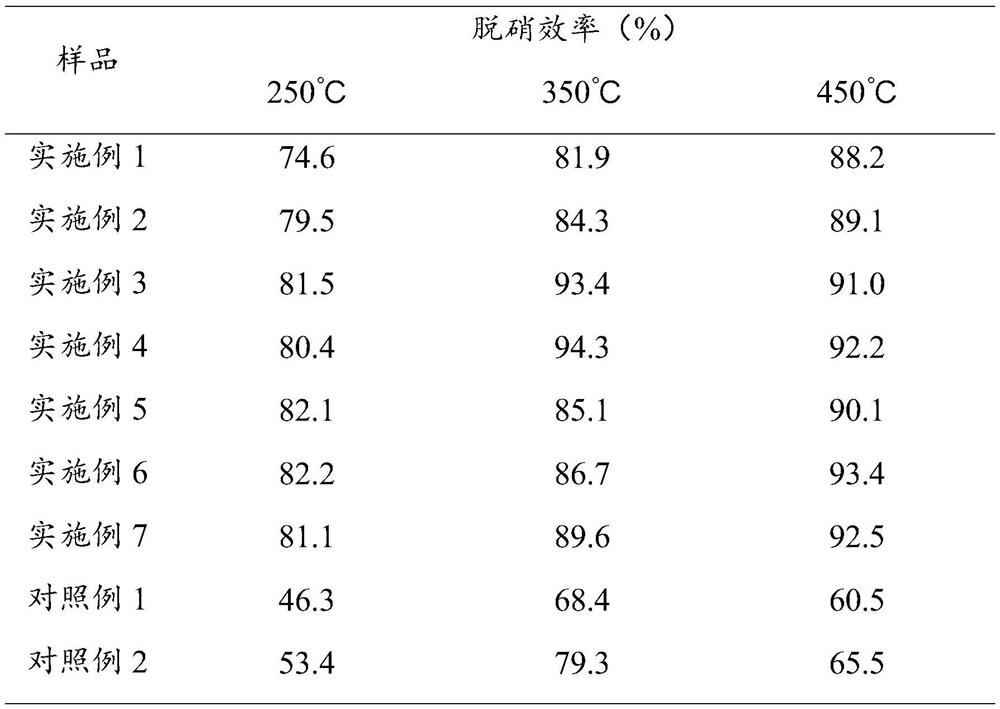

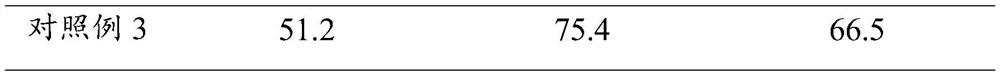

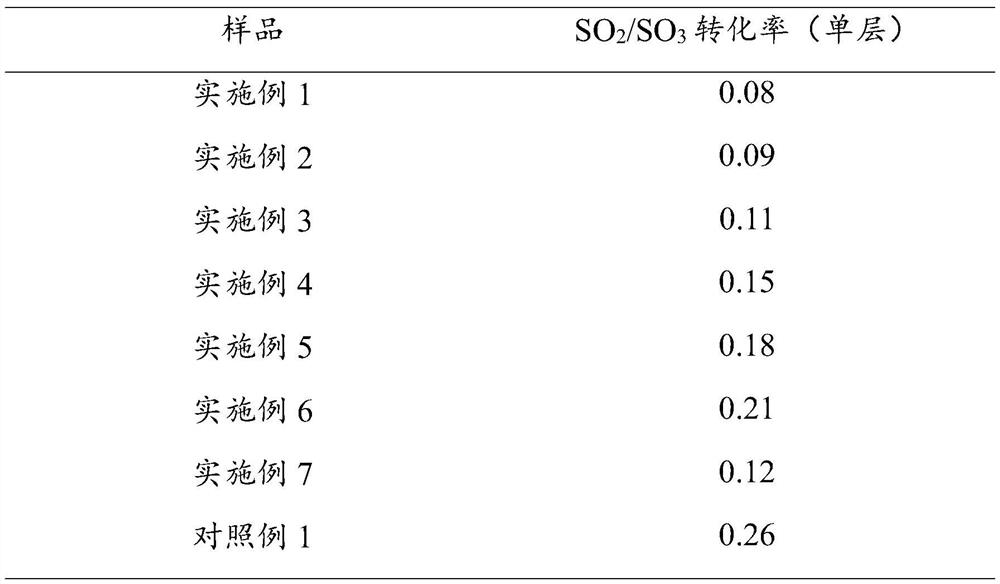

Examples

Embodiment 1

[0035] S11. Weigh ferric nitrate and place it in a crucible, add glycine, sodium chloride and deionized water to stir and dissolve, put the mixture in a muffle furnace and calcinate at 750°C for 4 hours, and cool to obtain powder A, wherein glycine and nitric acid The ratio of the amount of iron is 1:1, and the quality of sodium chloride is 5% of the quality of ferric nitrate;

[0036] S12. Weighing the titanium dioxide, and immersing the titanium dioxide in an aqueous solution of ammonium metavanadate and ammonium heptamolybdate, stirring and drying the water, calcining at 400° C. for 4 hours, and cooling to obtain powder B;

[0037] S13. Put powder A and powder B in a high-shear disperser, and shear and disperse at 16,000 rpm for 1 hour to prepare a denitration catalyst.

[0038] V of the prepared denitration catalyst 2 o 5 Content is 0.5%, MoO 3 The content is 8%, iron oxide content is 8%, and the rest is TiO 2 .

Embodiment 2

[0040] S21. Weigh aluminum nitrate and place it in a crucible, add glycine, sodium chloride and deionized water to stir and dissolve, put the mixture in a muffle furnace and calcinate at 800°C for 3 hours, and cool to obtain powder A, wherein glycine and nitric acid The ratio of the amount of aluminum is 1.5:1, and the quality of sodium chloride is 6% of the quality of aluminum nitrate;

[0041] S22. Weighing the titanium dioxide, and immersing the titanium dioxide in an aqueous solution of ammonium metavanadate and ammonium heptamolybdate, stirring and drying the water, calcining at 450° C. for 3.5 hours, and cooling to obtain powder B;

[0042] S23. Put powder A and powder B in a high-shear disperser, and shear and disperse at 15,000 rpm for 1.5 hours to prepare a denitration catalyst.

[0043] V of the prepared denitration catalyst 2 o 5 Content is 1%, MoO 3 The content is 5%, the alumina content is 6%, and the rest is TiO 2 .

Embodiment 3

[0045] S31. Weigh cerium nitrate and place it in a crucible, add glycine, potassium chloride and deionized water to stir and dissolve, put the mixture in a muffle furnace and calcinate at 800°C for 3 hours, and cool to obtain powder A, wherein glycine and nitric acid The ratio of the amount of cerium is 2:1, and the quality of potassium chloride is 8% of the quality of cerium nitrate;

[0046] S32. Weighing the titanium dioxide, and immersing the titanium dioxide in an aqueous solution of ammonium metavanadate and ammonium heptamolybdate, stirring and drying the water, calcining at 600° C. for 1 hour, and cooling to obtain powder B;

[0047] S33. Put powder A and powder B in a high-shear disperser, and shear and disperse at 14,000 rpm for 2 hours to prepare a denitration catalyst.

[0048] V of the prepared denitration catalyst 2 o 5 Content is 2%, MoO 3 The content is 4%, the cerium oxide content is 4%, and the rest is TiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com