Nano magnetic microsphere with hollow core-shell structure as well as preparation method and application of nano magnetic microsphere

A nano-magnetic, core-shell structure technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve problems such as unsuitable for large-scale promotion, reduction of surface energy, loss of dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

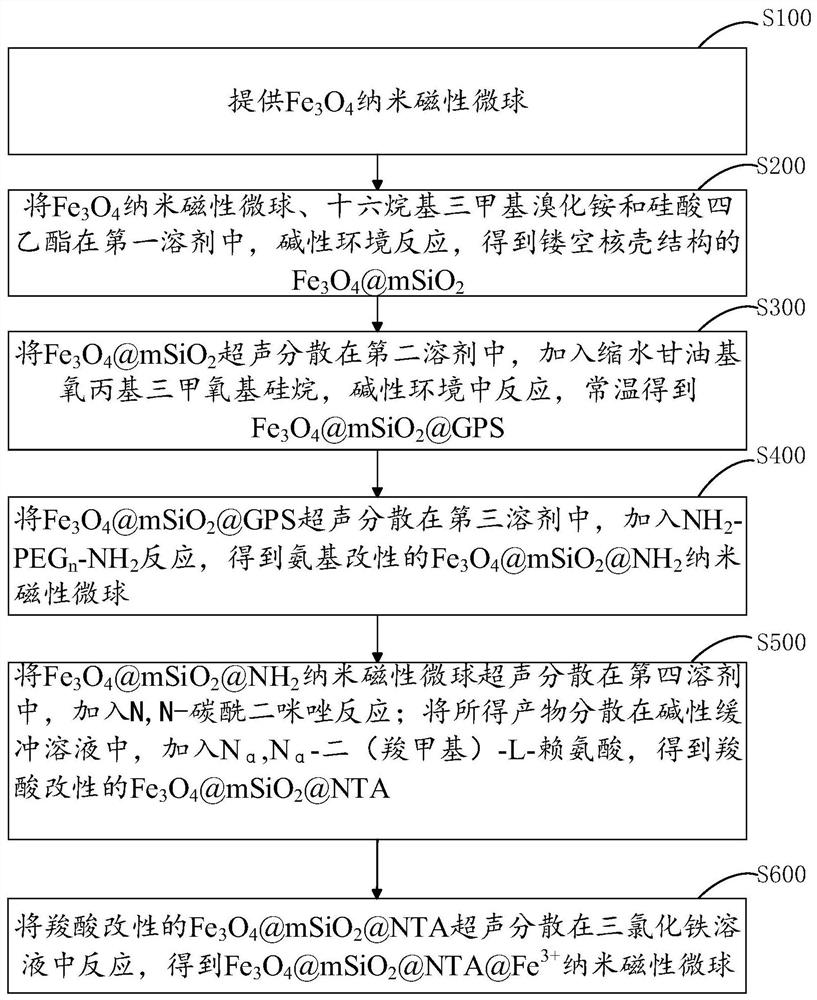

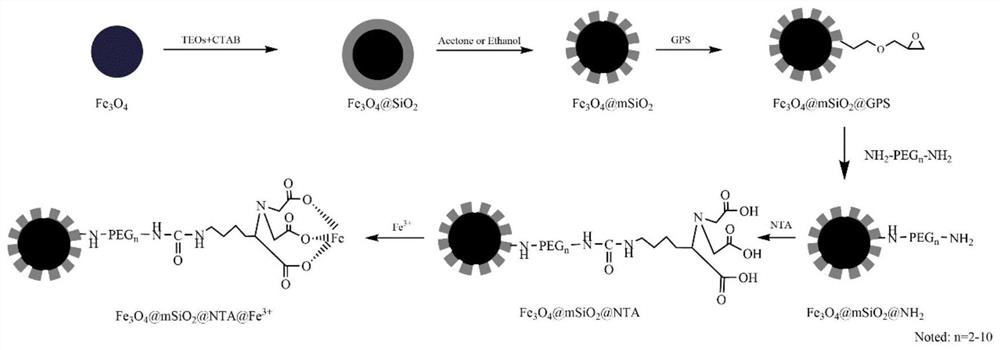

[0038] Such as figure 1 As shown, the embodiment of the present disclosure provides a method for preparing nano-magnetic microspheres with a hollow core-shell structure, including:

[0039] S100, providing Fe 3 o 4 Nano magnetic microspheres;

[0040] S200, the Fe 3 o 4 Nano-magnetic microspheres are ultrasonically dispersed in ethanol, and hexadecyltrimethylammonium bromide, tetraethyl silicate and ammonia water are added in sequence to react to obtain Fe with a hollow core-shell structure. 3 o 4 @mSiO 2 ;

[0041] S300, the Fe 3 o 4 @mSiO 2 Ultrasonic dispersion in ethanol, followed by adding ammonia and glycidyloxypropyltrimethoxysilane to react to obtain Fe 3 o 4 @mSiO 2 @GPS;

[0042] S400, the Fe 3 o 4 @mSiO 2 @GPS ultrasonic dispersion in THF, adding NH 2 -PEG n -NH 2 reaction to obtain amine-modified Fe 3 o 4 @mSiO 2 @NH 2 Nano magnetic microspheres;

[0043] S500, the Fe 3 o 4 @mSiO 2 @NH 2 Nanomagnetic microspheres are ultrasonically disp...

Embodiment 1

[0073] Embodiment 1 Preparation of hollow core-shell structure nano-magnetic microspheres

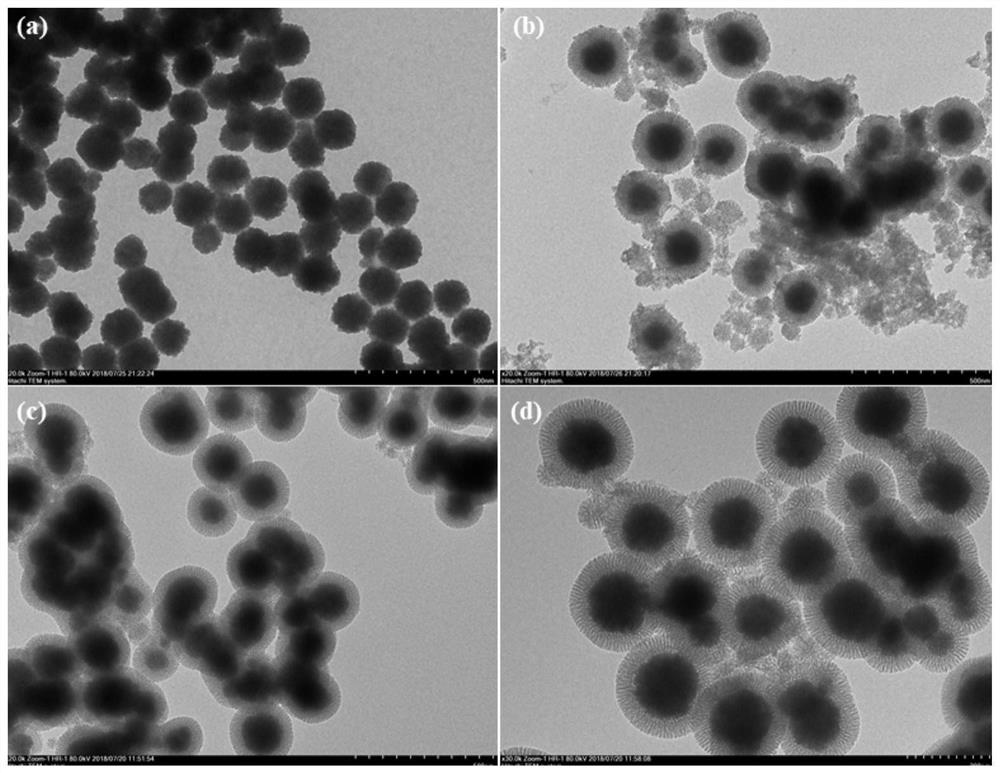

[0074] 1. Ultrasonic disperse 0.2M ferric chloride in 40ml of mixed solution of sodium citrate, anhydrous sodium acetate and ethylene glycol. The mass ratio of the three substances in the mixed solution is 1:80:400. The mixed solution After heating and dissolving in an oil bath, put the reaction solution in an autoclave and react at 200°C for 10 hours. After the reaction, wash the product with 20ml of water and ethanol three times in sequence to obtain Fe with uniform particles. 3 o 4 Nano magnetic microspheres. The resulting Fe 3 o 4 Electron microscope image of nanomagnetic microspheres image 3 as shown in a.

[0075] 2, the Fe obtained in step 1 3 o 4 Ultrasonic dispersion in 60ml of aqueous solution containing 60% ethanol, sequentially add cetyltrimethylammonium bromide, tetraethyl silicate and ammonia water under the condition of mechanical stirring, wherein cetyltrimethyla...

Embodiment 2

[0087] Example 2 Purification of phosphorylated polypeptides in β-casein using hollow-core-shell nano-magnetic microspheres

[0088] 1. Dissolve 1mg β-casein in 1ml 50mM ammonium bicarbonate buffer to obtain a 1mg / ml β-casein solution;

[0089] 2. Take 10ugβ-casein, add trypsin according to the ratio of 1:50, carry out enzyme digestion for 12 hours under the condition of 37°C water bath, add trifluoroacetic acid with a final concentration of 1% after enzyme digestion to terminate the enzyme digestion reaction, and vacuum dry Afterwards, the β-casein digestion peptide was obtained;

[0090] 3. Use 100ul binding buffer (1% trifluoroacetic acid, 80% acetonitrile) to combine the Fe prepared in Example 1 3 o 4 @mSiO 2 @NTA@Fe 3+ Wash three times and set aside;

[0091] 4. Dissolve the peptide obtained in step 2 in 100ul binding buffer, and transfer to a well-balanced Fe 3 o 4 @mSiO 2 @NTA@Fe 3+ Magnetic microspheres in a centrifuge tube, and evenly disperse the magnetic mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com