A kind of recombinant escherichia coli producing glycolic acid and its construction method and application

A technology for recombining Escherichia coli and Escherichia coli, applied in microorganism-based methods, other methods of inserting foreign genetic materials, applications, etc., to achieve the effects of enhancing synthesis, enhancing expression, and reducing the loss of carbon and sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0219] The construction of embodiment 1 recombinant escherichia coli engineering strain GA00-GA07

[0220] 1. Construction of a recombinant plasmid (pYB1s-ghrA) expressing glyoxylate reductase derived from large intestine.

[0221] (1) Extraction of Escherichia coli genomic DNA and PCR amplification of ghrA gene.

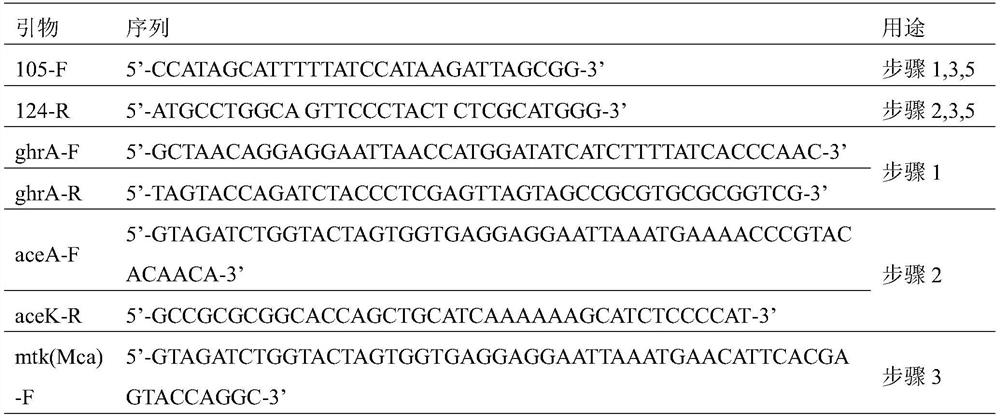

[0222] Genomic DNA of Escherichia coli BW25113 was extracted using a bacterial genome extraction kit (Tiangen Biochemical Technology Co., Ltd., product catalog DP302). Using the total genomic DNA extracted from Escherichia coli as a template, using ghrA-F and ghrA-R as primers (Table 1), high-fidelity TransStart FastPfu DNA polymerase (Beijing Quanshijin Biotechnology Co., Ltd., product catalog AP221) was used for PCR amplification. The PCR product was obtained, and the PCR product was subjected to agarose gel electrophoresis, and the target fragment was recovered to obtain the gene fragment ghrA-NX comprising the gene ghrA (nucleotide sequence shown in SEQ ID No.2...

Embodiment 2

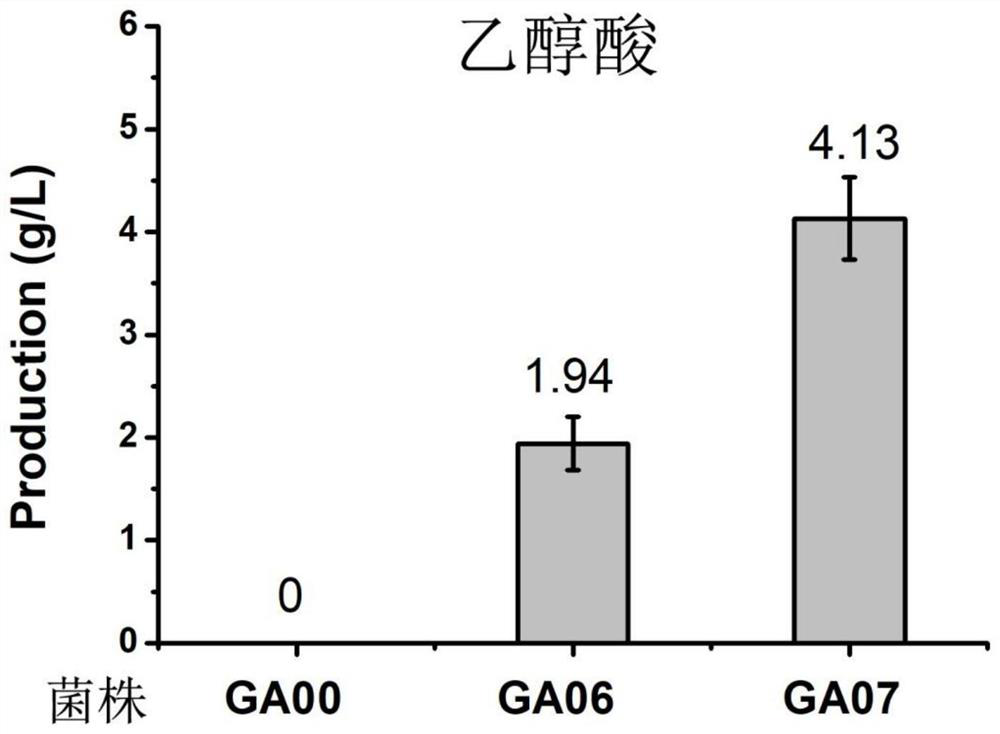

[0259] Example 2 Production of Glycolic Acid Using Recombinant Escherichia coli Strains GA00, GA06, and GA07 Using Glucose as a Raw Material

[0260] 1. The formula of the culture medium

[0261] (11) The composition of LB medium is as follows:

[0263] Peptone: 10g / L

[0264] NaCl: 10g / L

[0265] (12) The formula of self-induction medium ZYM is as follows:

[0266] 100mL A+2mL B+2mL C+200μL D+100μL E (the following are mass percentage concentrations);

[0267] A.ZY: 1% tryptone, 0.5% yeast powder;

[0268] B.50×M: 1.25M Na 2 HPO 4 , 1.25M KH 2 PO 4 , 2.5M NH 4 Cl and 0.25M Na 2 SO 4 ;

[0269] C.50×5052: 25% glycerol, 2.5% glucose, 10% L-arabinose;

[0270] D.500×MgSO 4 : 1M MgSO 4

[0271] E.1000×trace elements: 50mM FeCl 3 , 20mM CaCl 2 , 10mM MnCl 2 , 10mM ZnSO 4 , CoCl 2 、NiCl 2 、Na 2 Mo 4 、Na 2 SeO 3 and H 3 BO 3 2mM each.

[0272] (13) The composition of the conversion solution is as follows:

[0273] Glucose 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com